Calculate Volumes by Five Methods

For this tutorial, we'll be using a sample stockpile drawing and

calculating its volume using five distinct techniques:

- Stockpile Volumes:

Creates grid surfaces from perimeter polyline and surface entities

and calculates volumes in one command

- Volumes By Layers:

Creates grid surfaces from existing and design layers and

calculates volumes in one command

- Two Grid Surface

Volumes: Calculates volumes between two grid

files

- Volumes By

Triangulation: Calculates volumes between two

triangulation files

- Calculate Sections

Volumes: Calculates volumes between two section files

using volumes by average end areas

Each of these routines has its own advantages. You can choose

the routine that best suits your data or run multiple methods as a

check of the volumes. The volume reports for each of these routines

will vary slightly due to using different types of surface models

that have different resolutions. These volume differences should be

less than 2%.

A Results Summary of the various volume

methodologies is also provided.

If there is a greater difference, try increasing the resolution

of the surface models. For grids, make the grid cell size smaller

and for sections, make the station interval smaller. If there is

still a significant difference, then the cause should be

investigated by checking the source data.

Common Steps

The following are common preparation steps for all five volume

methods:

- Click the Windows desktop icon for Carlson to start the

program.

- If you get the Start Page, pick

Open Files.

- If you get the Startup Wizard

dialog box, click the Browse button.

- If you are taken directly into CAD, click File --

Open.

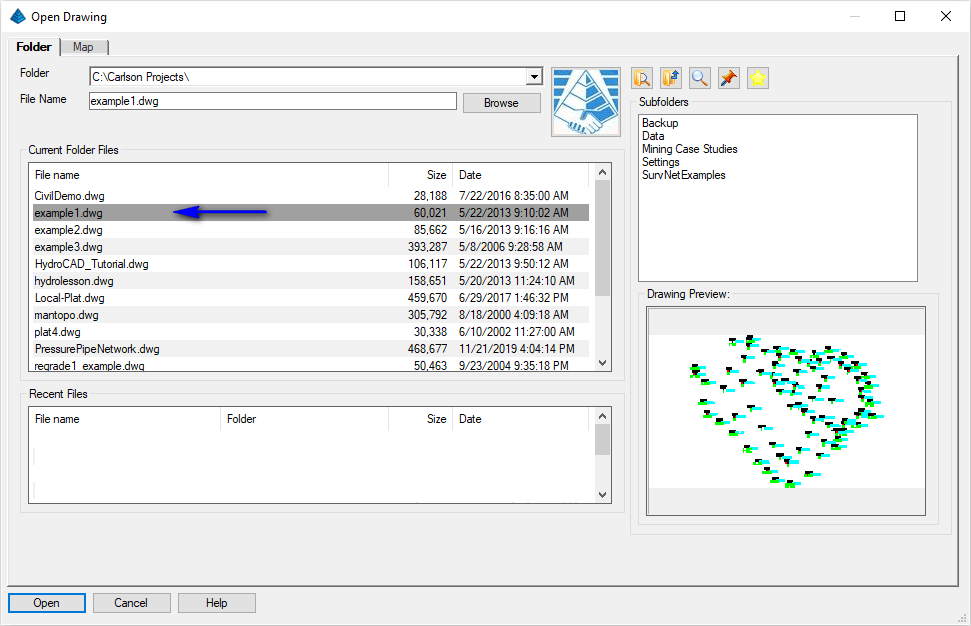

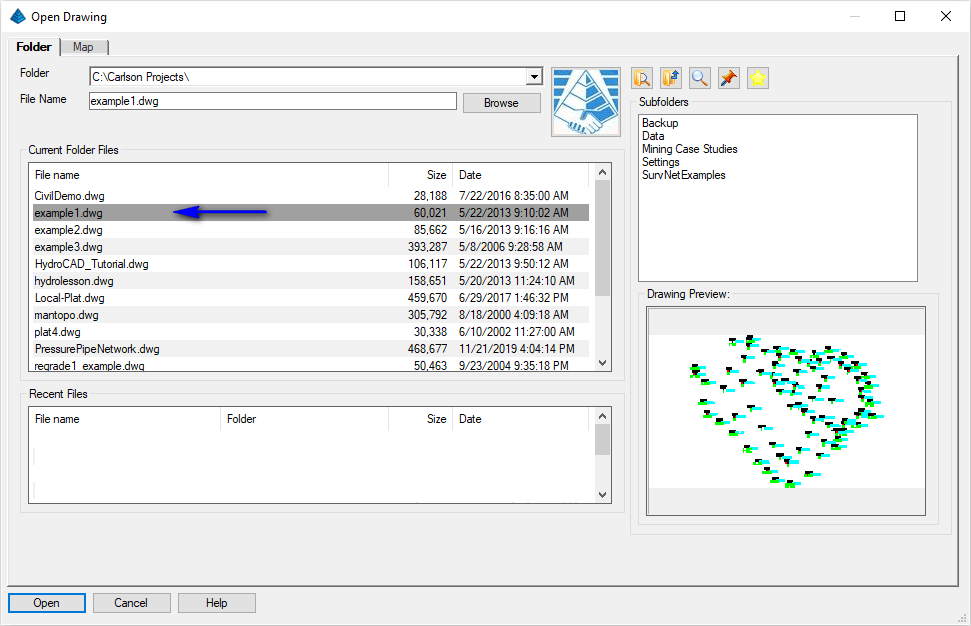

Browse/navigate to the default folder location of

C:\Carlson Projects and open the

example1.dwg file.

Use the File -- Save As to save a copy named

example1-v.dwg. Completing this tutorial will

alter the drawing file and by renaming the file from the start,

you'll keep the original file intact (allowing you to run through

the tutorial a second time if desired). This is also a good

practice to keep when working on drawings from 3rd parties.

- Ensure you are in the Civil program by issuing the

Settings -- Carlson Menus -- Civil Menu command.

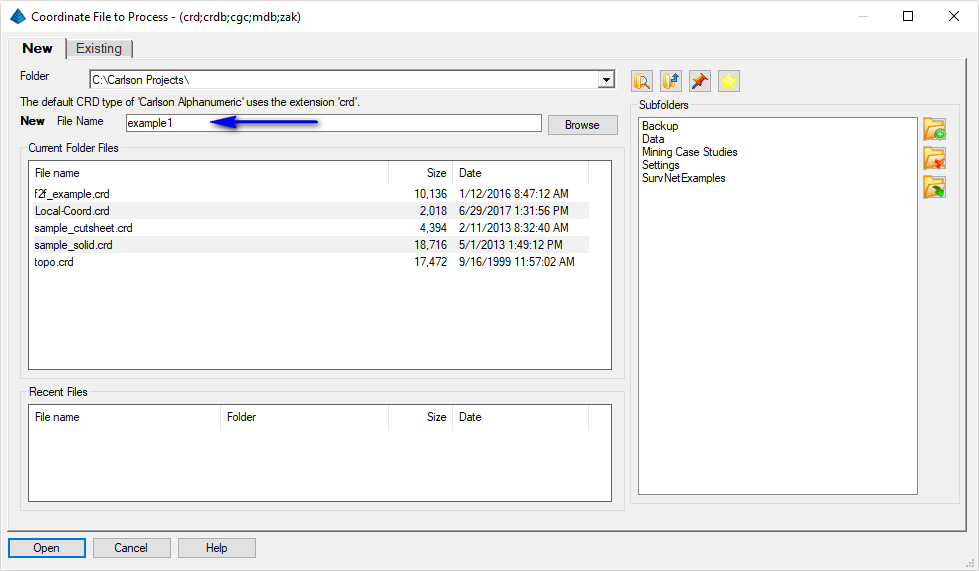

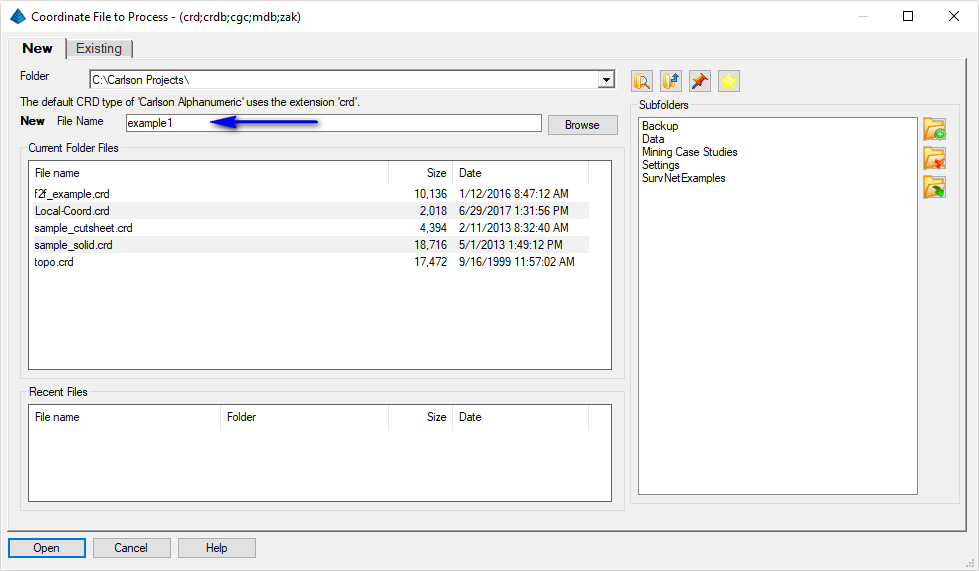

Since our drawing contains point data, let's house it in a related

coordinate file for future use. Issue the Points --

Set

Coordinate File command to display a dialog box similar to that

shown below:

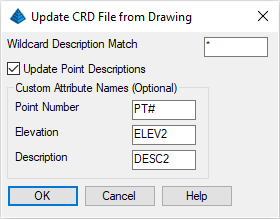

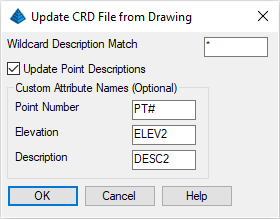

Set the value as shown above and click Open when

ready. Next, issue the Points -- Point Utilities --

Update CRD File from Drawing command (also found under Points

--

Coordinate File Utilities) to display a dialog box similar to

that shown below:

Accept the default values and click OK when ready.

When prompted:

Select Carlson, LDD, Softdesk, InRoads,

EaglePt, Geodimeter, Leica or MicroSurvey Points.

[FILter]/<Select entities>:

type ALL and press Enter

[FILter]/<Select entities>:

press Enter

- Due to the shape of the data (and in an effort to get

consistent results), we'd like to develop a boundary (or

inclusion) polyline around the data set. There are several

ways to accomplish this:

- Through the use of the Survey module

and its Survey -- Draw

Field to Finish command, or,

- Through the use of the Draw -- 3D Polyline

command, or,

- Through the use of the Draw -- Shrink-Wrap

Entities command, or,

- Through the use of the Surface --

Stockpile/Pond/Pit Volumes --

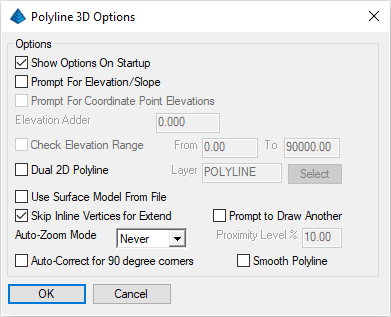

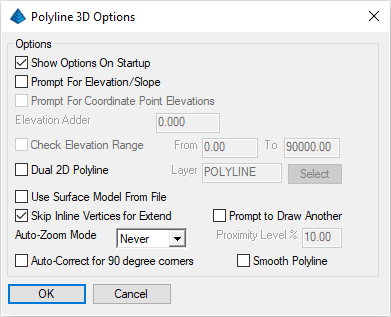

Draw 3DPoly Perimeter command (run it now) to display a dialog

box similar to that shown below:

Set the values

as shown above (click OK when ready) and when

prompted:

Set the values

as shown above (click OK when ready) and when

prompted:

[Continue/Extend/Follow/Options/<Pick point

or point numbers>]: type the range

of 2000-2028 and press Enter

[Arc/Close/Distance/Extend/Follow/Line/Undo/<Pick point

or point numbers>]: type C and press

Enter

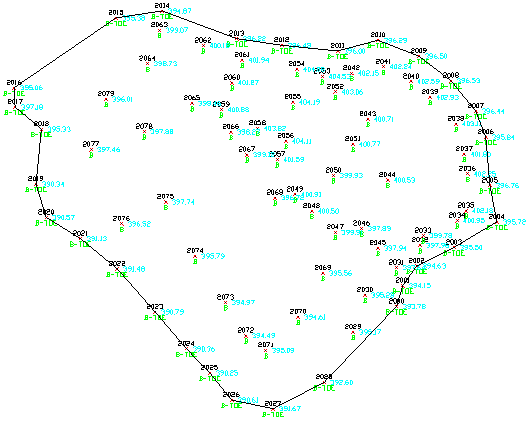

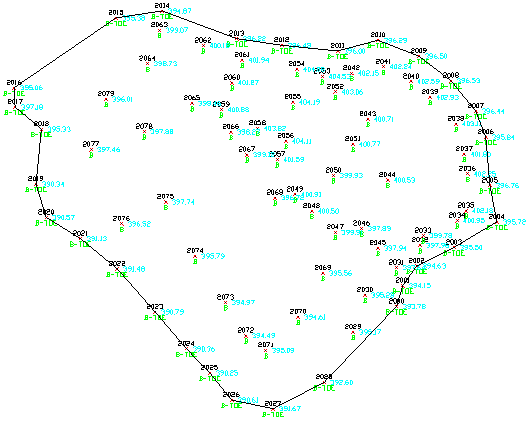

The drawing should resemble that shown below:

Let's begin the volume calculation processes.

Volume Method 1 - Calculate Stockpile Volume

The Calculate Stockpile Volume routine is based

on a grid surface methodology like the Two Surface Volumes discussion below. The

difference with this routine is that it builds the grid surfaces

within the routine to save time otherwise needed to build the grid

files. The fewer steps make this routine faster and easier but it

doesn't have options for checking surfaces. Instead the input data

entities should be checked before running this routine. Also,

Calculate Stockpile Volume only applies to volumes

calculations when the volume is all Fill.

- Issue the Surface -- Stockpile/Pond/Pit Volumes --

Calculate Stockpile Volume command. When prompted:

Select stockpile entities and

perimeter.

[FILter]/<Select entities>:

type ALL and press Enter (The program

looks for a closed 3D polyline on the PERIMETER layer to use as the

inclusion perimeter and the base surface model. If this polyline is

not found, then the program will prompt to select the perimeter

polyline. All the selected entities including the perimeter are

used to model the second surface of the stockpile top).

[FILter]/<Select entities>:

press Enter

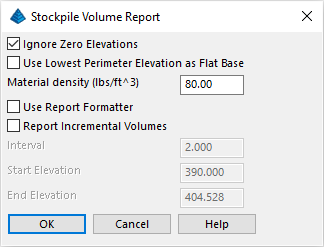

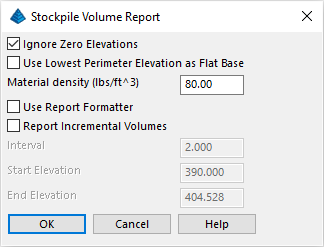

The routine offers various reporting capabilities. Let's assume a

typical density for a pile of road salt as illustrated below and

click OK when ready:

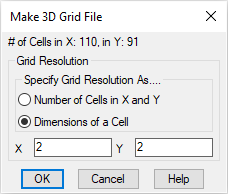

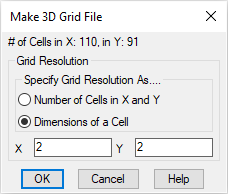

Specify the grid resolution as shown in the dialog below and click

OK when ready:

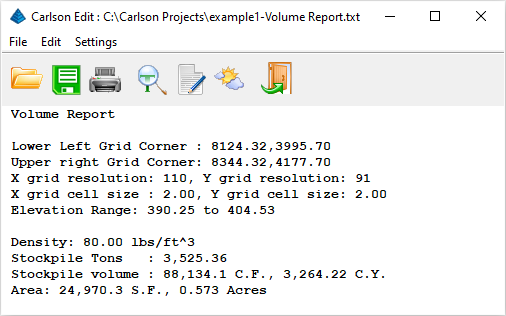

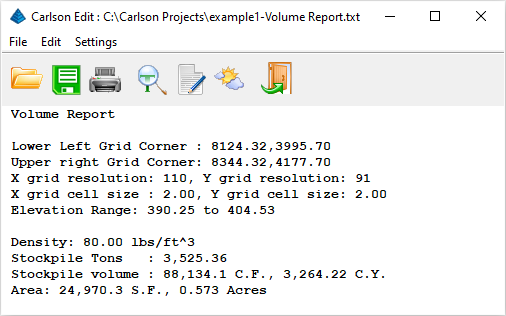

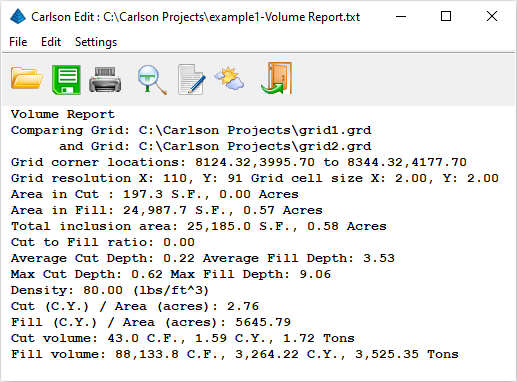

The result is summarized in a volume report in the

Standard Report Viewer similar to that shown below:

Click the Exit (Doorway) button to dismiss the

report.

NOTE: The limits of the grid are determined

automatically and shown in the report. For the sake of accuracy,

the next two methods will use the grid parameters shown above.

NOTE: For situations involving a Cut-only

scenario (such as a pond or pit), use the Surface --

Stockpile/Pond/Pit Volumes --

Calculate Pond/Pit Volume command.

Volume Method 2 - Volumes By Layers

Let's explore a simple routine that handles both Cut and Fill

scenarios.

- Issue the Surface -- Volumes By Grid Surface --

Volumes By Layers command. When prompted:

Pick Lower Left limit of surface area

<8124.32,3995.70>: indicate the

values shown to the left and press Enter (or pick a lower

left limit)

Pick Upper Right limit of surface area

<8344.32,4177.70>: indicate the

values shown to the left and press Enter (or pick an upper

right limit)

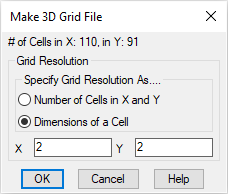

Specify the grid resolution as shown in the dialog below and click

OK when ready:

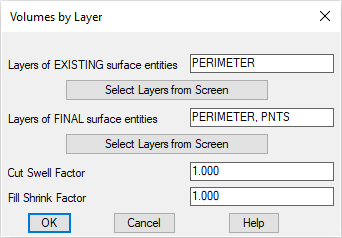

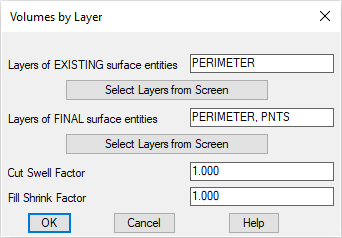

A dialog box similar to that shown below appears:

Click the Select Layers from Screen buttons and

when prompted:

- Select entities on layers of Existing

surface.

[FILter]/<Select entities>:

pick the PERIMETER polyline and press

Enter

- Select entities on layers of Final

surface.

[FILter]/<Select entities>:

type ALL and press Enter twice

Once the values are as shown above, click OK when

ready. Prompting resumes:

Select surface entities on corresponding

layers.

[FILter]/<Select entities>:

type ALL and press Enter twice

Select the Inclusion perimeter polylines or

ENTER for none:

[FILter]/<Select entities>:

pick the PERIMETER polyline and press

Enter

[FILter]/<Select entities>:

press Enter

Select the Exclusion perimeter polylines or

ENTER for none.

[FILter]/<Select entities>:

press Enter

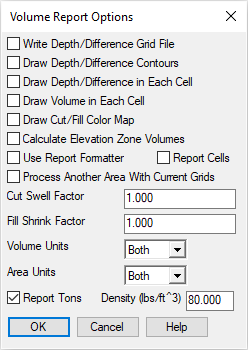

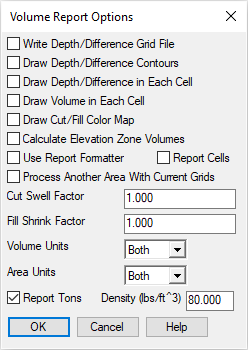

Volume Report Options (dialog):

set the values as shown below and click

OK when ready:

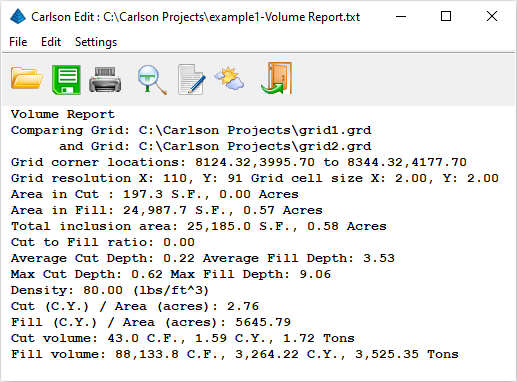

The volume report similar to that shown below appears:

Click the Exit (Doorway) button to dismiss the

report.

NOTE: Similar to Calculate

Stockpile Volume, this routine builds the grid surfaces within

the routine to save the steps of creating grid files. The

difference between this routine and the Calculate Stockpile

Volume routine is that Volumes By Layers uses

entities on specified layers for Existing and

Final scenarios to build the surfaces and it will

calculate both Cut and Fill volumes.

Volume Method 3 - Two Grid Surface Volumes

For the next example, we must create the two grid files; one

representing an assumed base-ground (Existing) surface,

the other representing the surface of the pile

(Final).

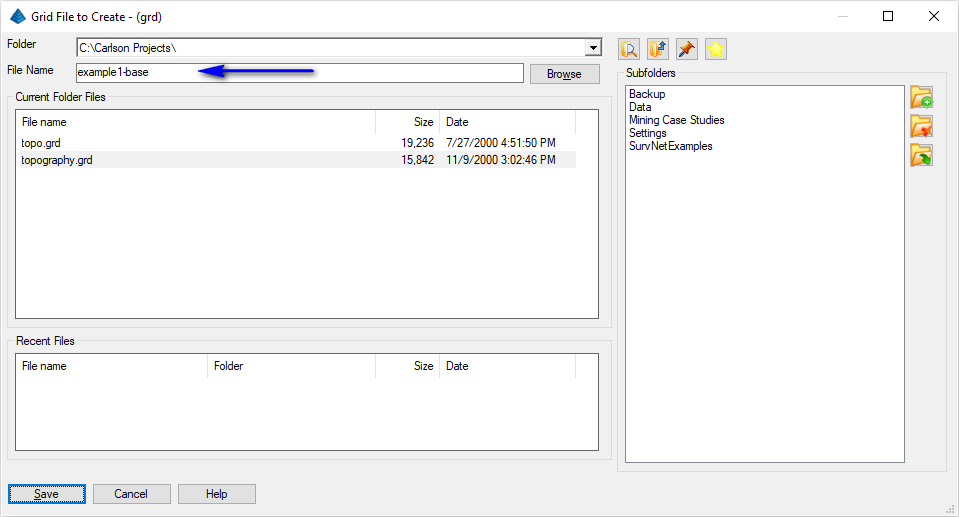

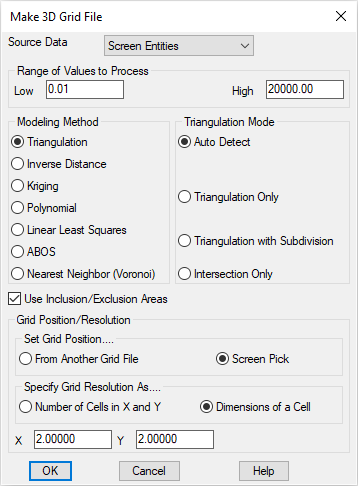

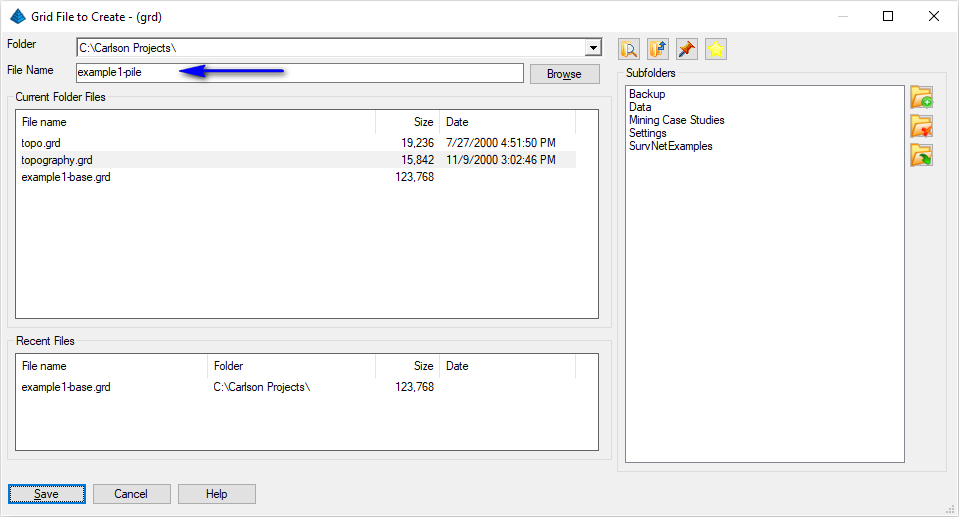

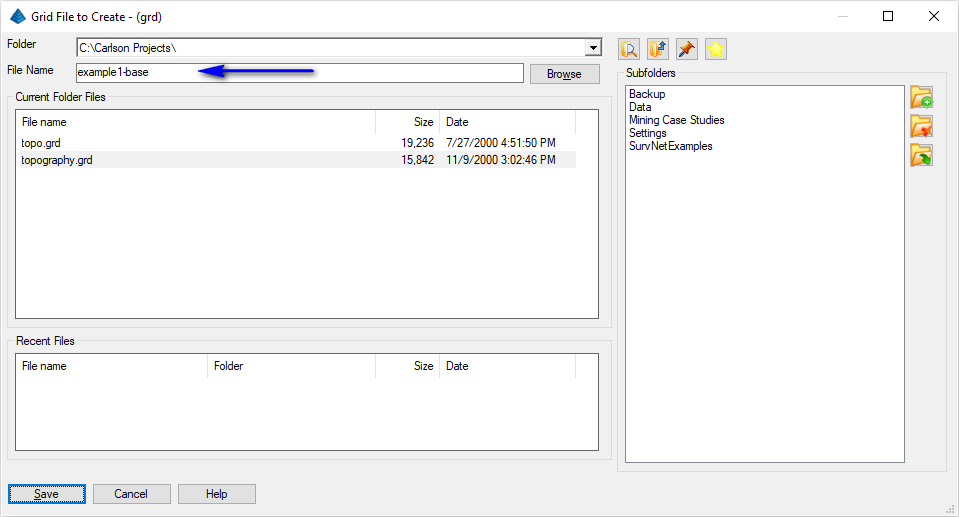

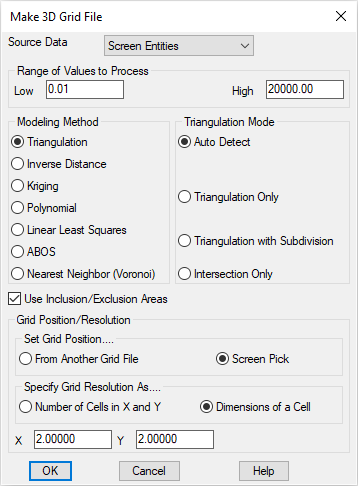

- Issue the Surface --

Make 3D Grid File command. When prompted:

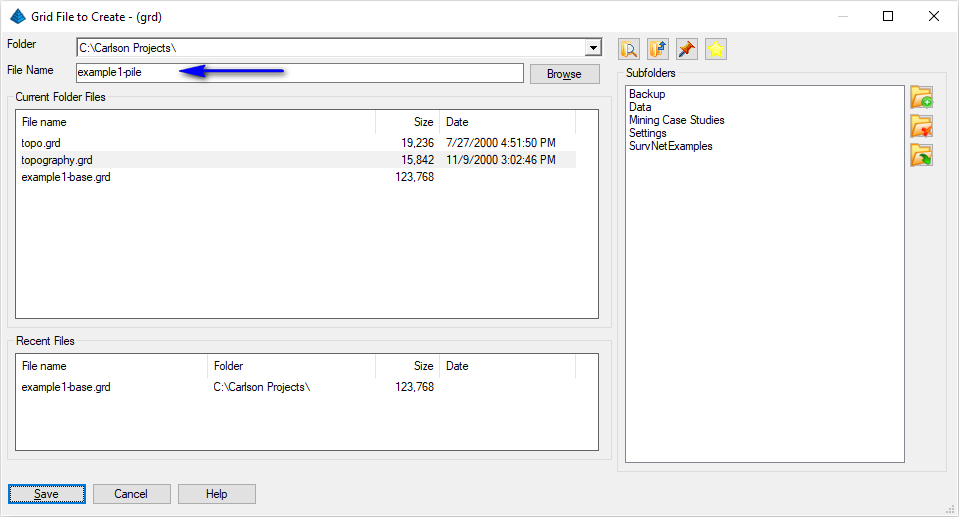

Grid File to Create (dialog):

supply the file name indicated below and click

Save when ready:

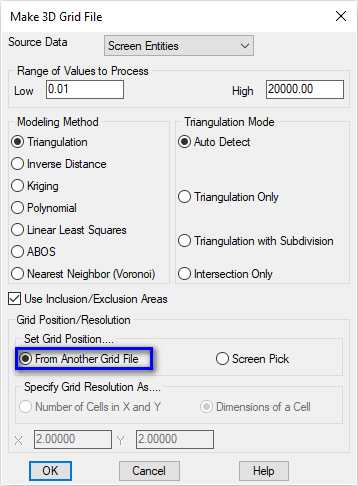

A dialog box similar to that shown below appears. Set the values as

shown and click OK when ready:

Prompting resumes:

Pick first grid corner

<8124.32,3995.70>: press

Enter (notice the grid limit from the previous example is

defaulted)

Pick opposite grid corner

<8344.32,4177.70>: press

Enter

Select the Inclusion perimeter polylines or

ENTER for none.

[FILter]/<Select entities>:

pick the PERIMETER polyline

[FILter]/<Select entities>:

press Enter

Select the Exclusion perimeter polylines or

ENTER for none.

[FILter]/<Select entities>:

press Enter

Select points, lines, polylines and faces to

grid from.

[FILter]/<Select entities>:

pick the PERIMETER polyline again and press

Enter

[FILter]/<Select entities>:

press Enter

A grid file representing an assumed base-ground (Existing)

surface is written.

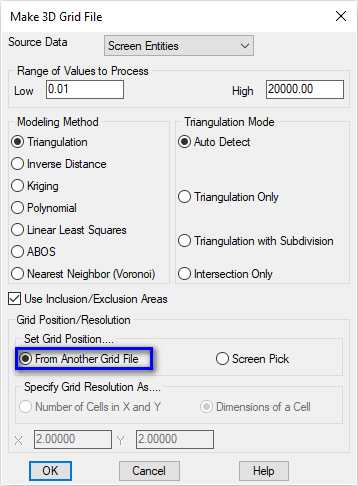

- Re-run the Surface -- Make 3D Grid File

command. When prompted:

Grid File to Create (dialog):

supply the file name indicated below and click

Save when ready:

A dialog box similar to that shown below appears. Set the values as

shown and click OK when ready:

NOTE: For the volume routine to follow, the two

grids to compare should have matching grid positions and

resolution. Prompting resumes:

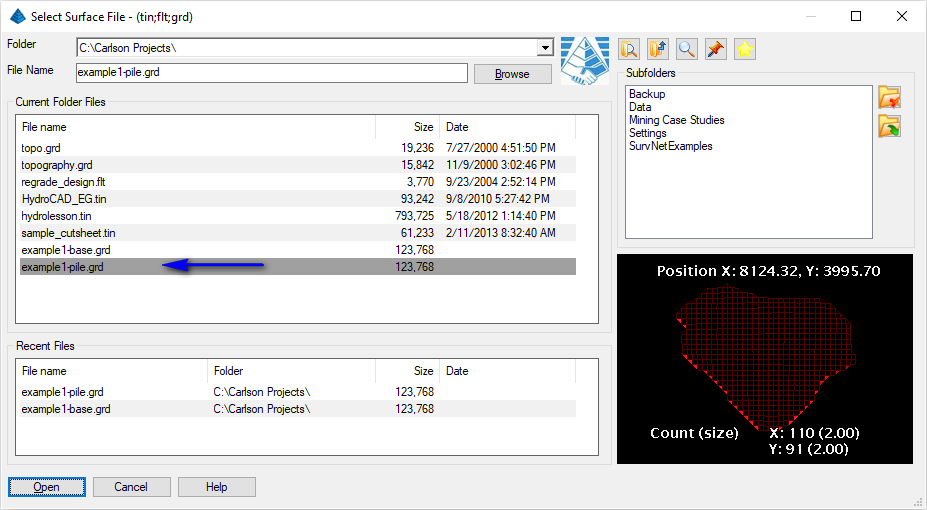

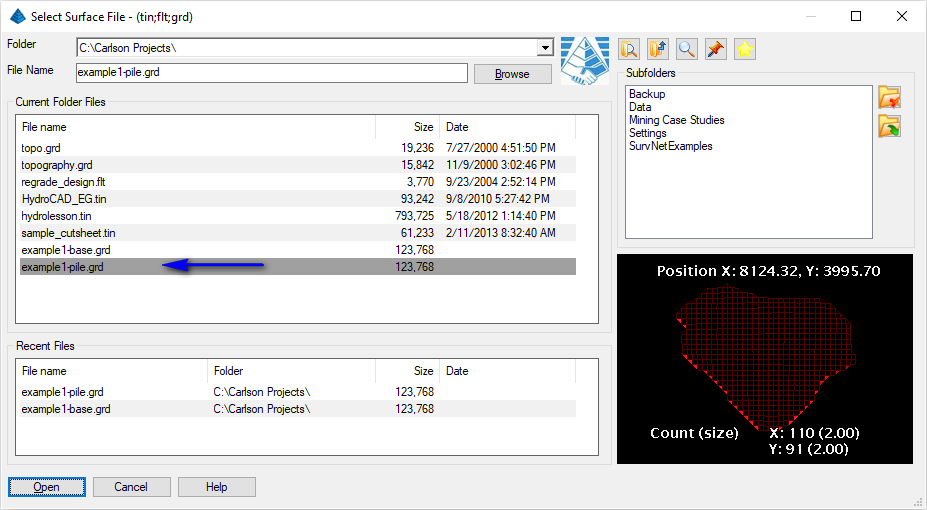

Grid File to Get Position From

(dialog): select the grid file created

earlier and click Open when ready

Select the Inclusion perimeter polylines or

ENTER for none.

[FILter]/<Select entities>:

pick the PERIMETER polyline

[FILter]/<Select entities>:

press Enter

Select the Exclusion perimeter polylines or

ENTER for none.

[FILter]/<Select entities>:

press Enter

Select points, lines, polylines and faces to

grid from.

[FILter]/<Select entities>:

type ALL and press Enter

[FILter]/<Select entities>:

press Enter

A grid file representing the surface of the pile (Final)

is written.

- Optional: Presume we might want to check

the surface(s) just created. This step is optional to verify that

the surfaces are good by checking for bad elevation data points and

that the surfaces follow the data points. Issue the View -- 3D View

-- Surface

File Viewer and when prompted:

Select Surface File (dialog):

select the grid file that was just created and

click Open when ready:

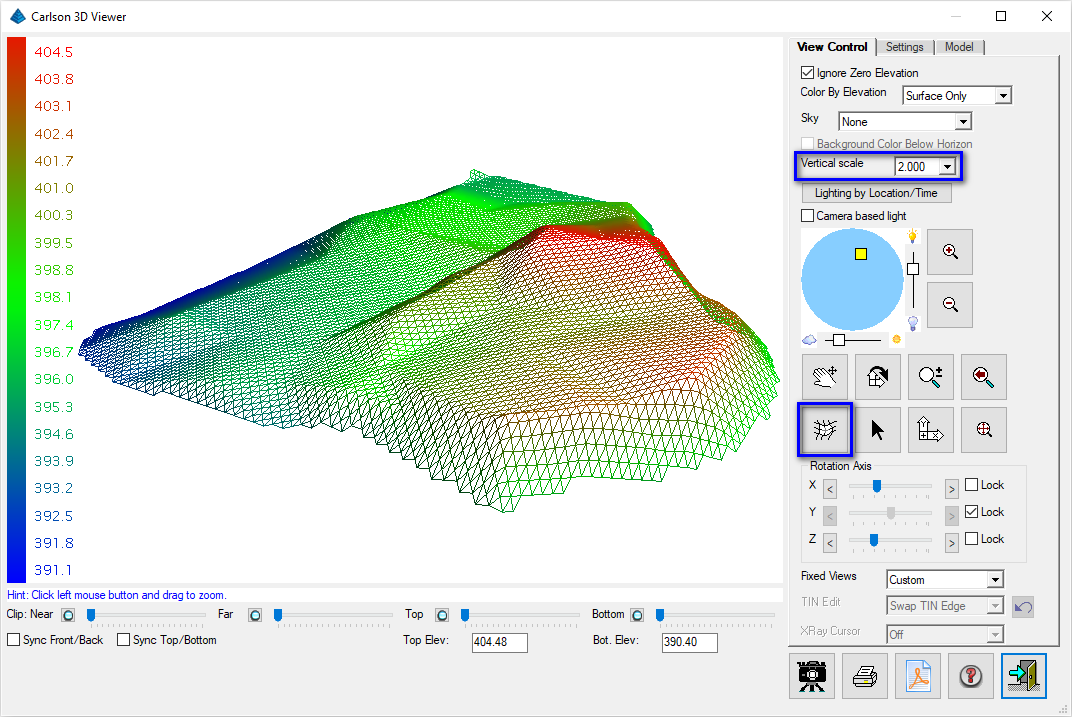

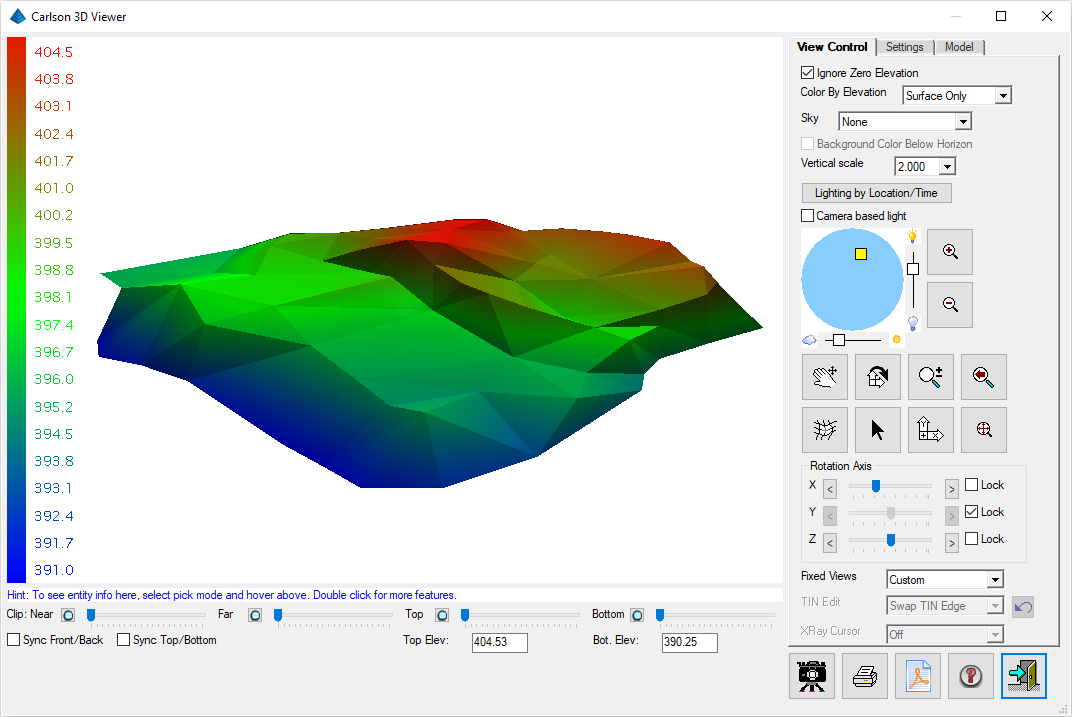

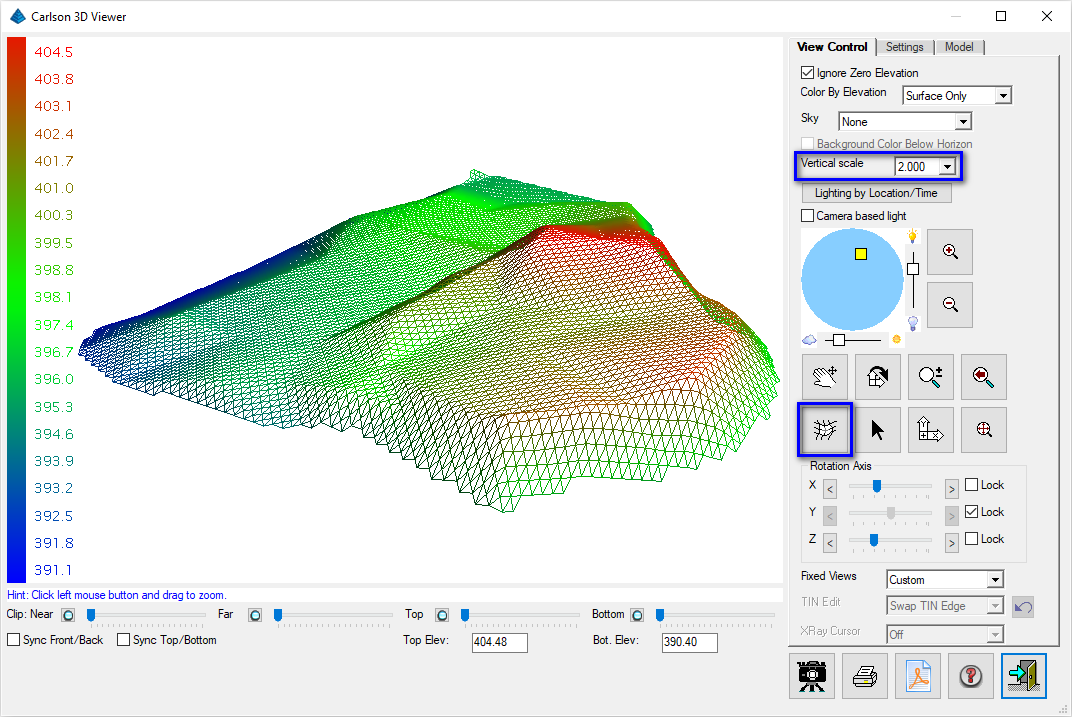

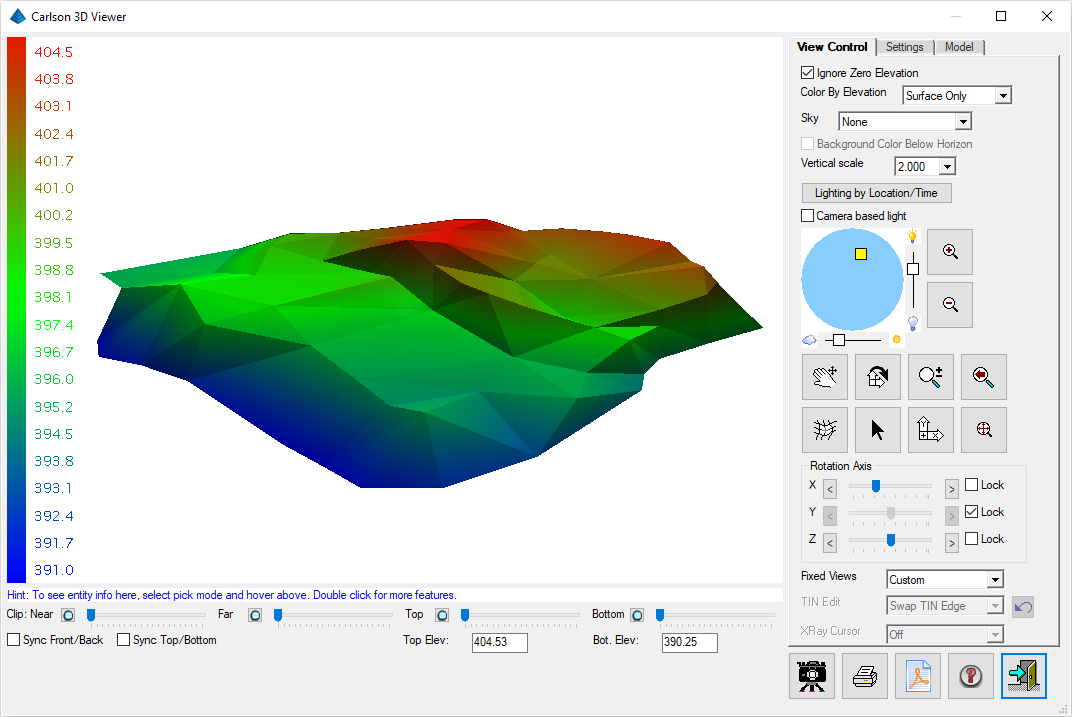

A 3D Viewer window similar to that shown below appears:

In the 3D Viewer dialog, move the pointer near the outer edge of

the graphic and the cursor will change to an Z symbol which orients

the view about the vertical axis. Moving the cursor to the interior

of the graphic and the cursor will change to an X/Y symbol. Click

and drag from the bottom upward to change the isometric viewing

angle. You can also set the Vertical Scale to 2.0

and enable the Color By Elevation toggle for

better viewing of the elevation difference. Experiment with any

desired remaining options. When ready, click the

Exit (Doorway) button.

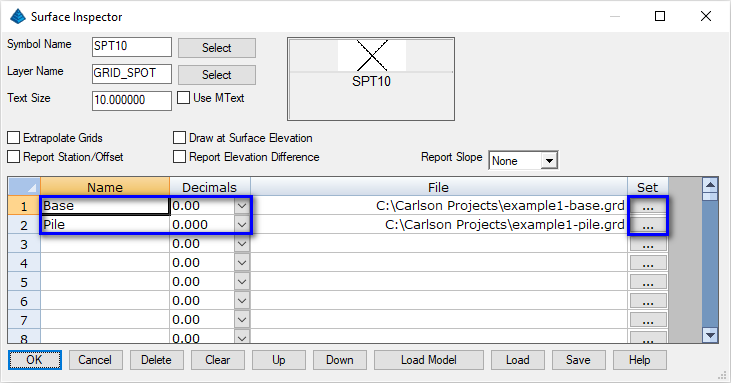

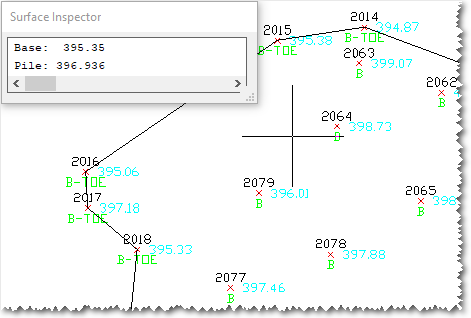

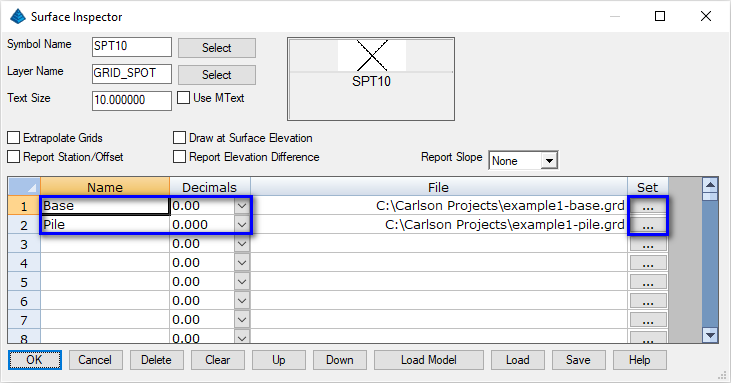

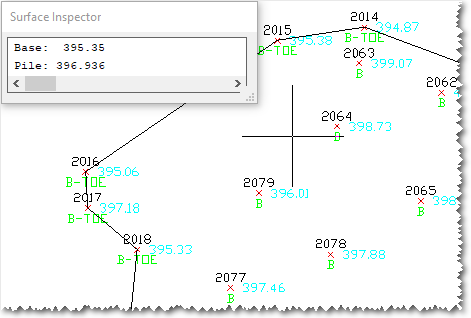

- Now, let's check some spot elevations. Issue the Surface --

Surface Inspector command to display a dialog box similar to

that shown below:

Use the highlighted controls to set the values as shown above. When

ready, click the OK button. As you position the

cursor into the data set, notice a real-time reporting of the two

surface elevations as illustrated below:

Check that the grid elevations match the point elevations

reasonably well. Remember that the base elevations are using only

the B-TOE points. The elevations won't match exactly with grid

surfaces because the grid model is at the resolution of the grid

cells. When finished checking, press Enter.

- Now that you have the Base and Pile grid

files, issue the Surface -- Volumes By Grid Surface --

Two Grid Surface Volumes command. When prompted:

Select the Inclusion perimeter polylines or

ENTER for none.

[FILter]/<Select entities>:

pick the PERIMETER polyline

[FILter]/<Select entities>:

press Enter

Select the Exclusion perimeter polylines or

ENTER for none.

[FILter]/<Select entities>:

press Enter

Select Base Grid File (dialog):

select the Base grid file and click

Open when ready

Select Final Grid File (dialog):

select the Pile grid file and click

Open when ready

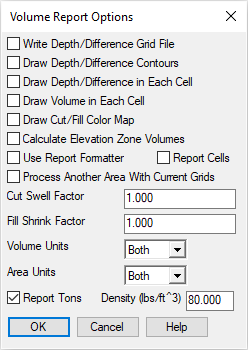

Volume Report Options (dialog):

set the values as shown below and click

OK when ready:

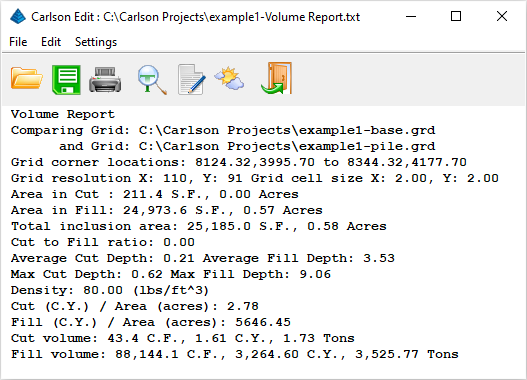

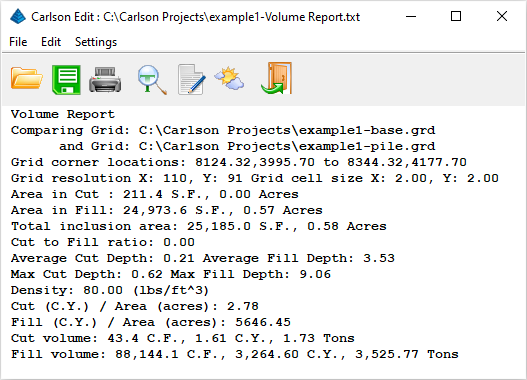

The volume report similar to that shown below appears:

Click the Exit (Doorway) button to dismiss the

report.

NOTE: Although grid files produce

relatively accurate volumes (based on the grid

resolution), their primary value lies in the ability to

hand-calculate the results for validation purposes. With a grid

resolution (e.g. 2' x 2') and the average elevation of

each grid cell (resulting in a grid depth), a grid cell volume can

be computed through traditional means.

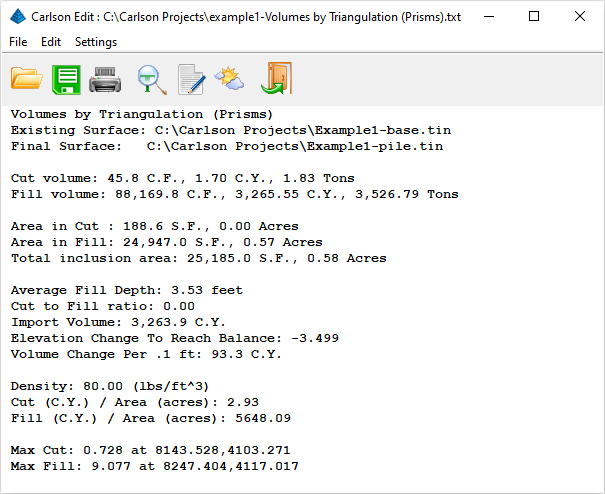

Volume Method 4 - Volumes By Triangulation

For precise surface-to-surface volumes, creating

triangulated irregular network (TIN) files is the

preferred methodology.

- Issue the Surface --

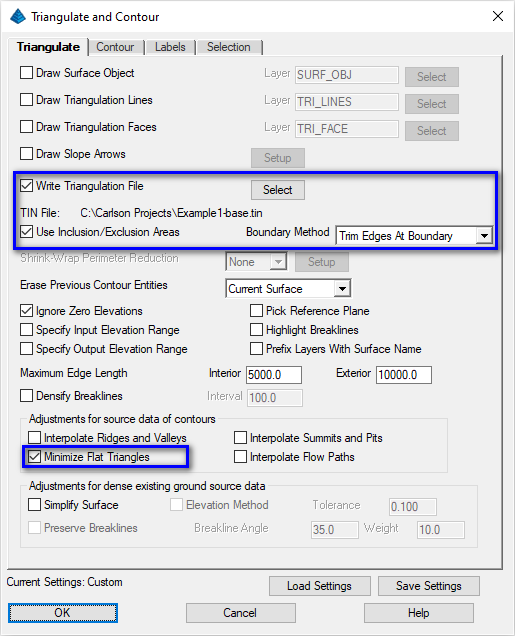

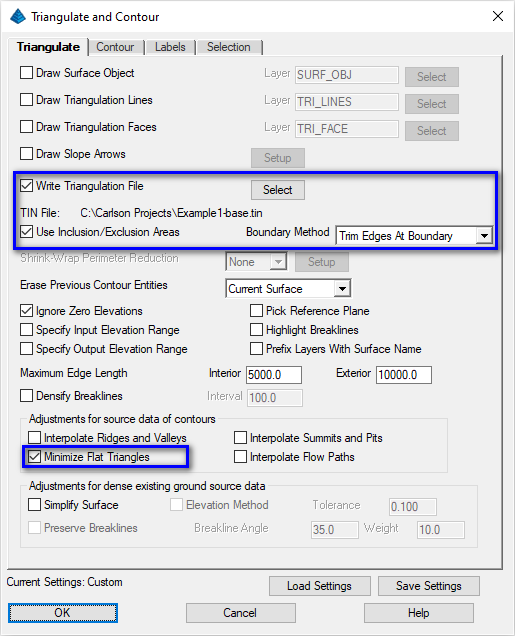

Triangulate & Contour command. The following dialog box

(with several "tabs") will appear which you should fill out as

discussed below:

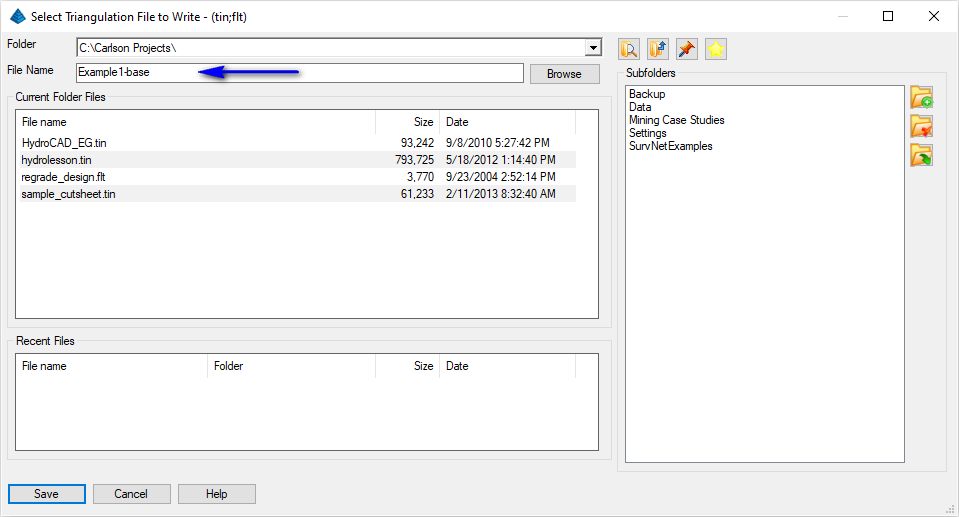

- In the Triangulate tab (as shown above), enable the

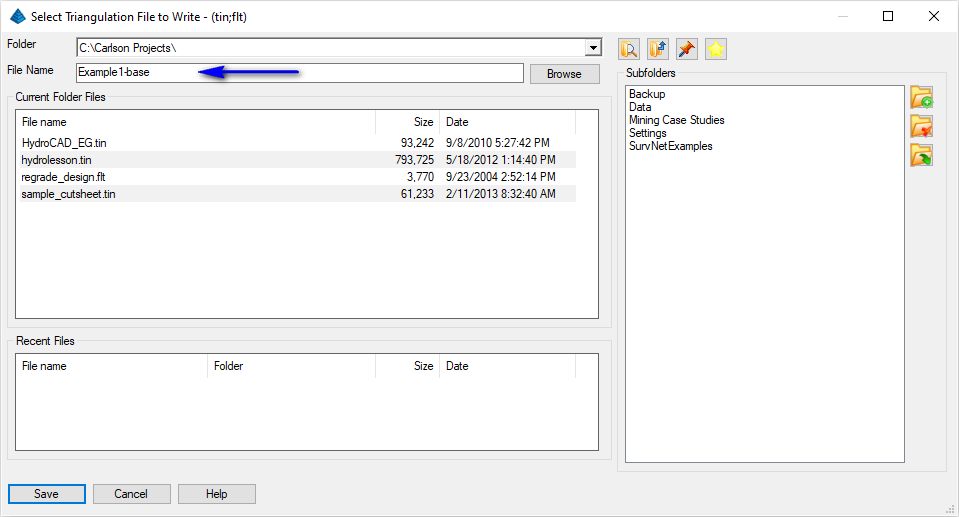

Write Triangulation File toggle and click its

Select button to set the name of a triangulation

(*.tin) file as illustrated below. Click the Save

button on this dialog box so that the results of the triangulation

can be re-used for future purposes. Turn on the Use

Inclusion/Exclusion Areas toggle and set any remaining

options as illustrated above:

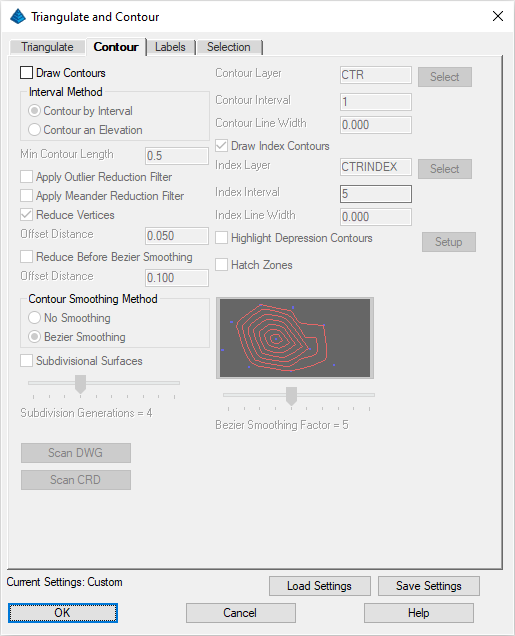

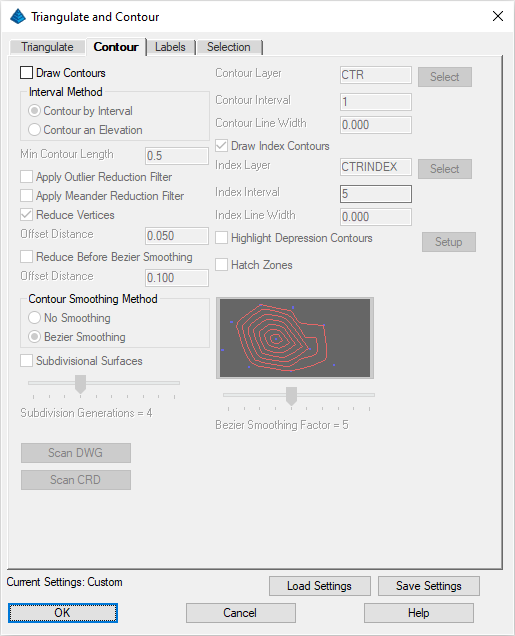

- In the Contour tab, as shown below, toggle off the

Draw Contours option:

Click the OK button from any tab. When prompted:

Select Inclusion perimeter polylines or ENTER

for none.

[FILter]/<Select entities>:

pick the PERIMETER polyline

[FILter]/<Select entities>:

press Enter

Select Exclusion perimeter polylines or ENTER

for none.

[FILter]/<Select entities>:

press Enter

Select points and breaklines to

Triangulate.

[FILter]/<Select entities>:

pick the PERIMETER polyline again and press

Enter

[FILter]/<Select entities>:

press Enter

If a secondary dialog box appears prompting for a coordinate file

(*.crd), click Cancel. A "TIN" file representing

an assumed base-ground (Existing) surface is written.

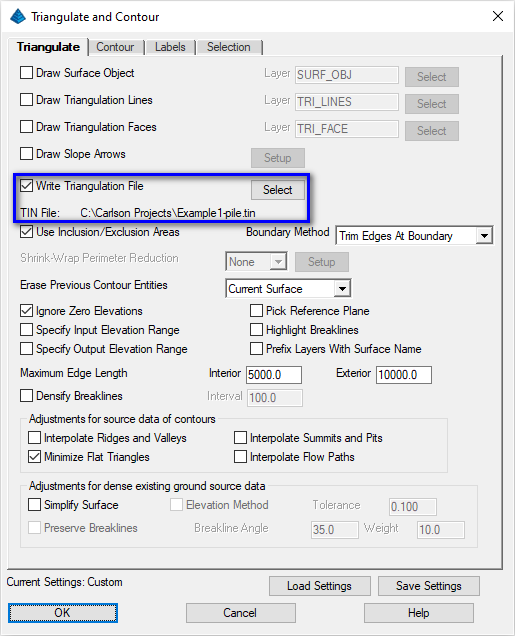

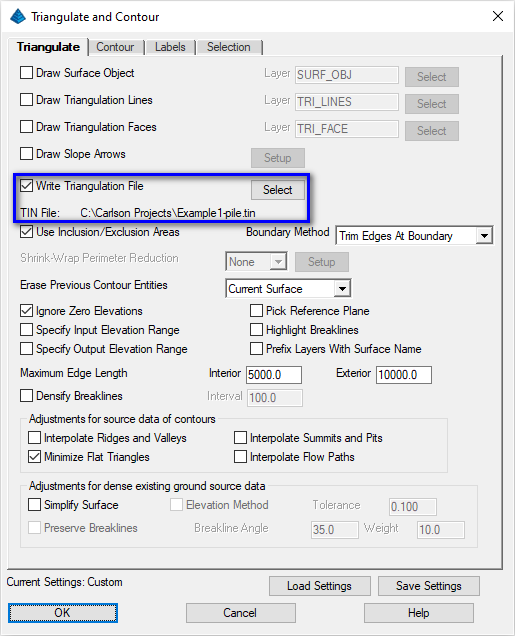

- For the pile TIN, we'll follow the same

general procedure as above but with a few small tweaks. Re-issue

the Surface -- Triangulate & Contour command

and set the values as shown below (click OK when

ready):

When prompted:

Select Inclusion perimeter polylines or ENTER

for none.

[FILter]/<Select entities>:

pick the PERIMETER polyline

[FILter]/<Select entities>:

press Enter

Select Exclusion perimeter polylines or ENTER

for none.

[FILter]/<Select entities>:

press Enter

Select points and breaklines to

Triangulate.

[FILter]/<Select entities>:

type ALL and press Enter

[FILter]/<Select entities>:

press Enter

If a secondary dialog box appears prompting for a coordinate file

(*.crd), click Cancel or select the coordinate file created earlier in this lesson if you

so choose and accept the default parameters that follow.

A "TIN" file representing the pile (Final) surface is

written.

- Optional: Similar to the Check Surfaces step under Two

Grid Surface Volumes, this is an optional step to check that

the surface(s) are correct. Re-issue the View -- 3D View --

Surface File Viewer command and when

prompted:

Select Surface File (dialog):

select the TIN file that was just created and

click Open when ready.

A 3D Viewer window similar to that shown below appears:

When ready, click the Exit (Doorway) button.

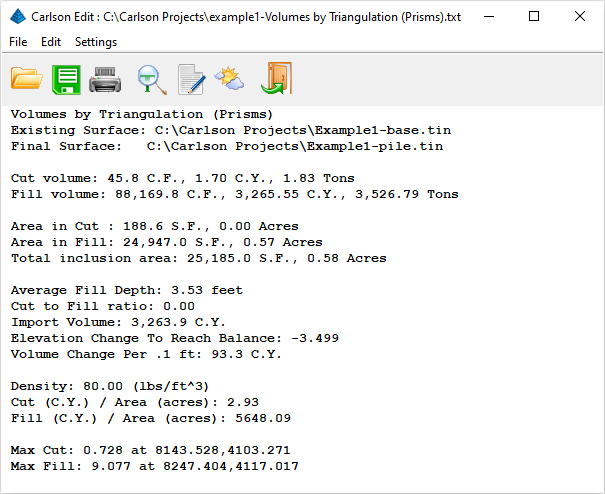

- Now that we have our two triangulation files, we can generate a

TIN to TIN prismoidal volume calculation. Of all the volume

methods, this one is the most accurate since all the source data

points are used in the volume model. Issue the Surface -- Volumes

By Triangulation --

Two Triangulation Surface Volumes command. When prompted:

Select EXISTING Surface Triangulation File

(dialog): select the Base TIN

file and click Open when ready

Select FINAL Surface Triangulation File

(dialog): select the Pile grid

file and click Open when ready

Select Inclusion perimeter polylines or ENTER

for none.

[FILter]/<Select entities>:

pick the PERIMETER polyline

[FILter]/<Select entities>:

press Enter

Select Exclusion perimeter polylines or ENTER

for none.

[FILter]/<Select entities>:

press Enter

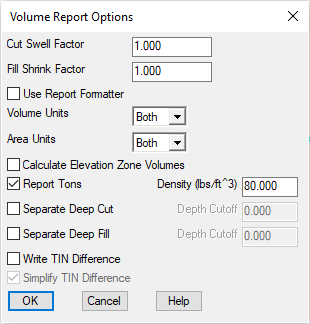

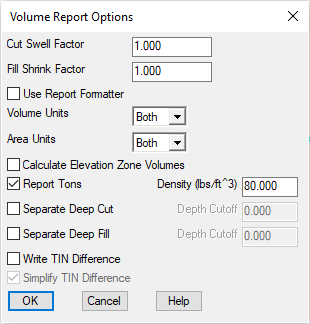

Volume Report Options (dialog):

set the values as shown below and click

OK when ready:

The volume report similar to that shown below appears:

Click the Exit (Doorway) button to dismiss the

report.

Volume Method 5 - Calculate Section Volumes

In roadway/corridor types of projects, volumes by Average

End Area are commonly used. Let's see the results of this

process.

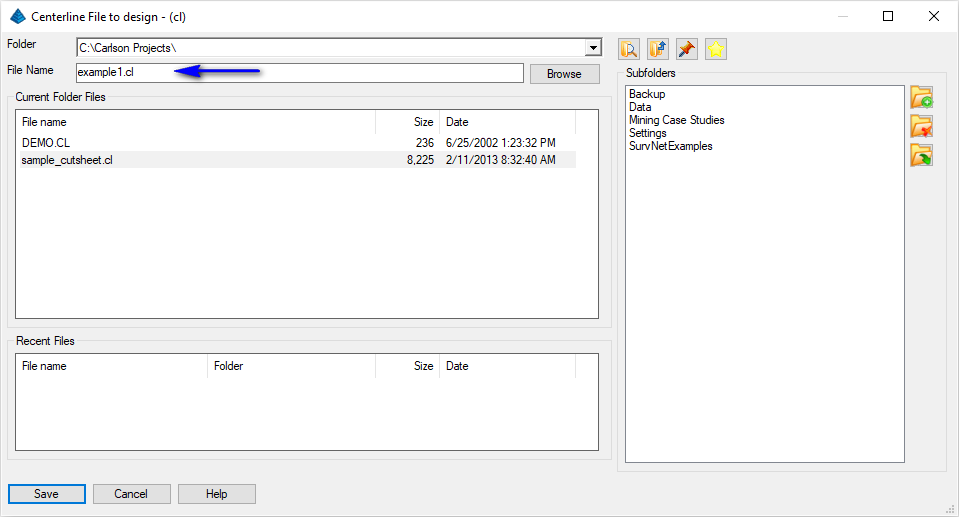

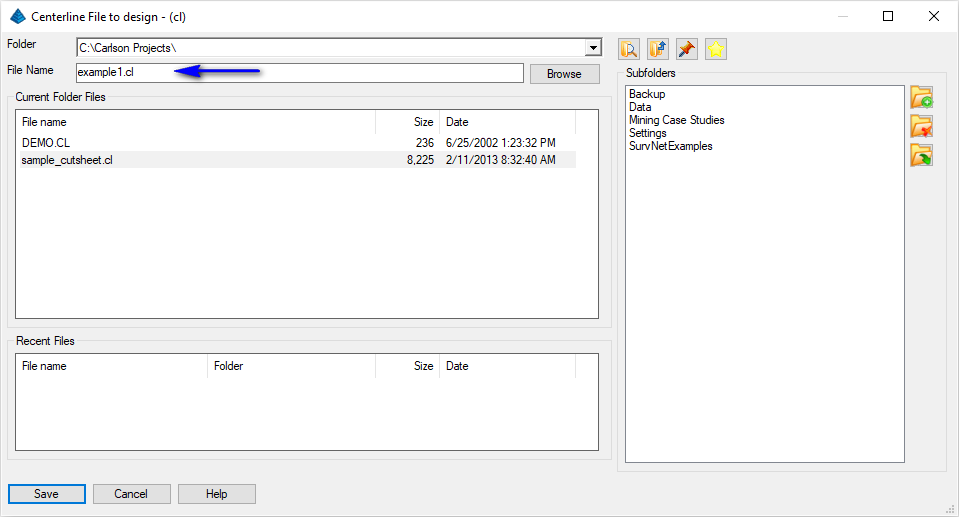

- Our first task will be to draw a centerline (baseline) upon

which the corridor will be based. Issue the Centerline --

Design Centerline command and when prompted:

Centerline File to Design (dialog):

set the file name as shown below and click

Open when ready

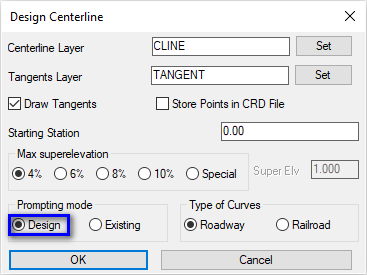

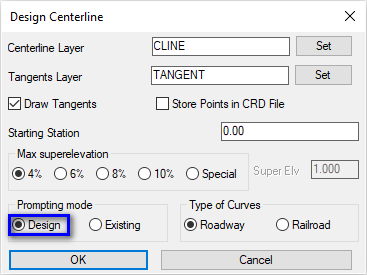

Design Centerline (dialog):

set the values as shown below and click

OK when ready

Design Centerline (dialog):

set the values as shown below and click

OK when ready

Pick Point or Point number:

type 2016 and press Enter

Pick Point or Point number:

type 2016 and press Enter

Bearing/PI/Exit/Undo/<Pick Point or Point

number>: type 2004 and press

Enter

Bearing/PC/PI/Exit/Undo/<Pick Point or

Point number>: press

Enter

A centerline is generated between the two points.

NOTE: Double-clicking on the polyline on the

screen will open the

Centerline Editor command.

- Our next task will be to establish the cross-section limits

along this corridor centerline. Issue the Sections --

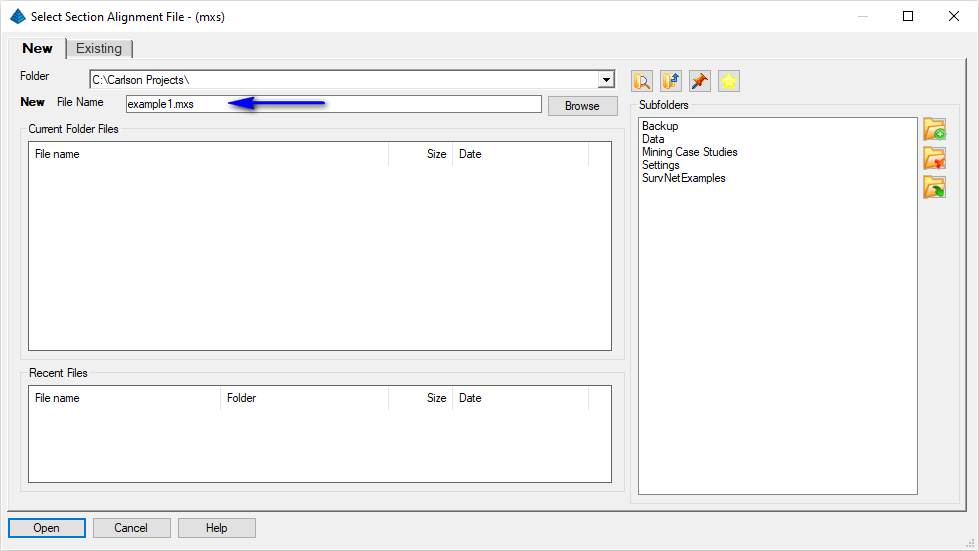

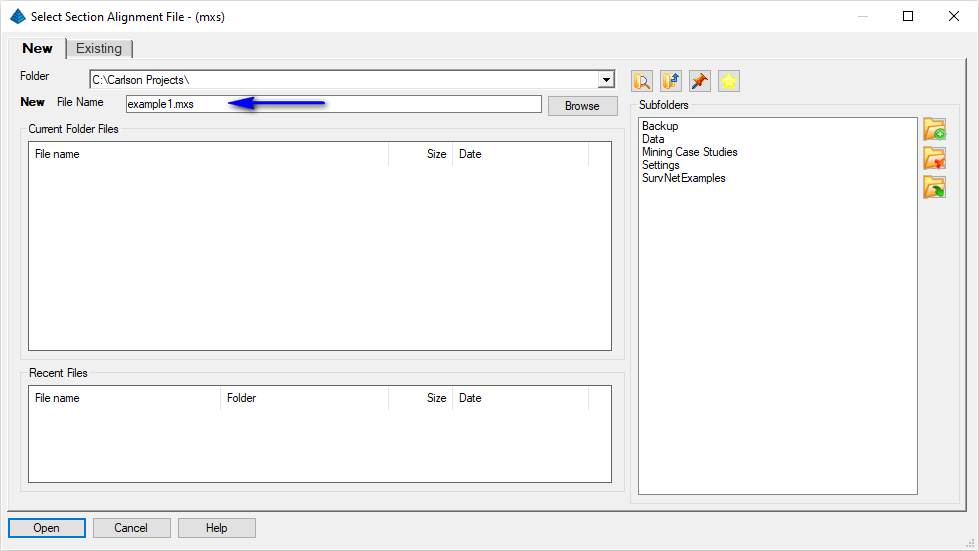

Section Alignment Editor to display a dialog box similar to

that shown below:

Set the file name as indicated above and click

Open when ready. When prompted:

Polyline should have been drawn in direction

of increasing stations.

CL File/<Select polyline that represents

centerline>: pick the centerline

polyline

Enter Beginning Station of Alignment

<0.00>: press Enter

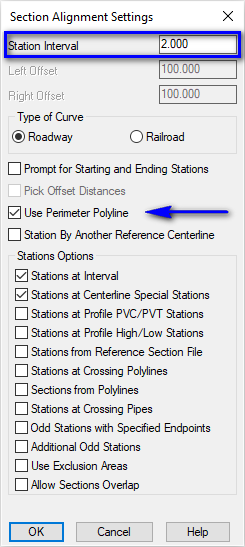

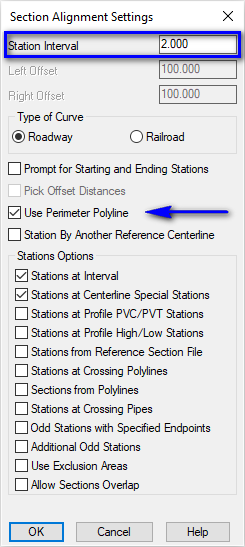

Section Alignment Settings (dialog):

set the values as shown below and click

OK when ready

Select boundary polyline: pick the PERIMETER polyline

The program draws temporary lines in the drawing to show the

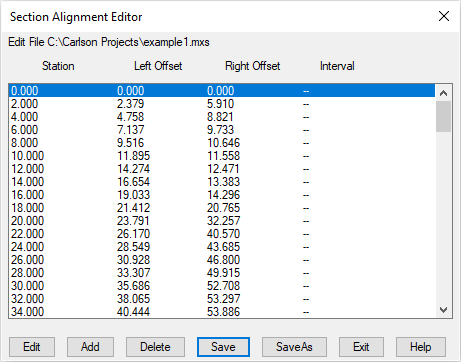

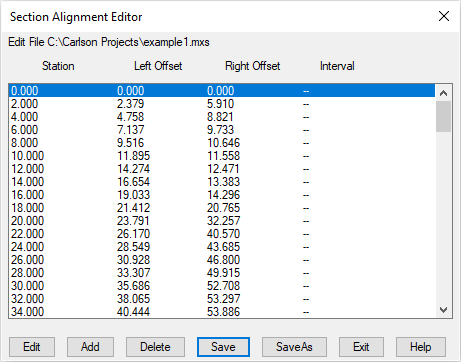

positions of the sections and displays a summary of the section

alignment as illustrated below:

Click the Save button followed by the

Exit button.

- To create the section file for the

Existing (base) surface, issue the Sections -- Create

Sections from... --

Sections from Grid or Triangulation Surface command. When

prompted:

Choose Grid or Triangulation file to Process

(dialog): specify the base.tin created earlier and click

Open when ready

Section Options (dialog): set the option to Prompt and click

OK when ready (with Prompt

specified, you'll be prompted if the Section should change if there

is an underlying change to the source TIN file)

Section Alignment File to Process

(dialog): specify the section alignment

(*.MXS) created earlier and click Open when

ready

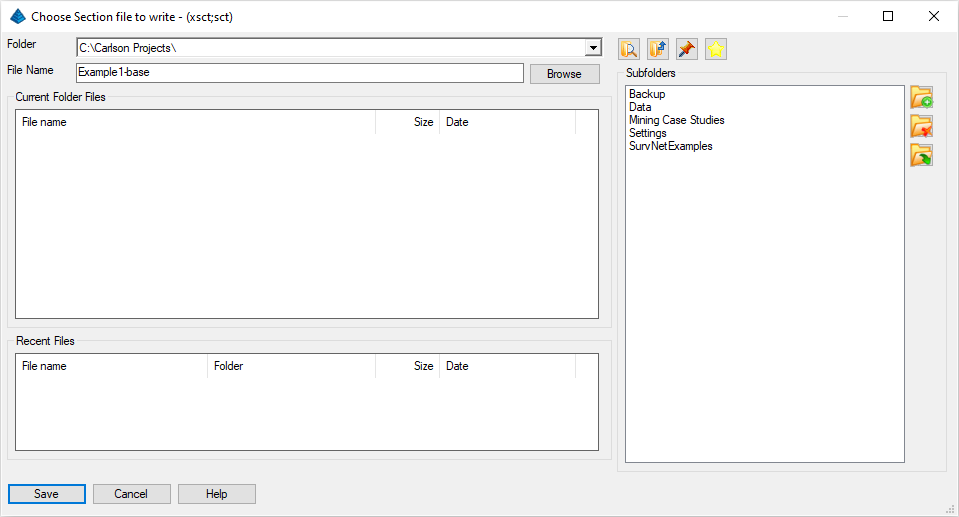

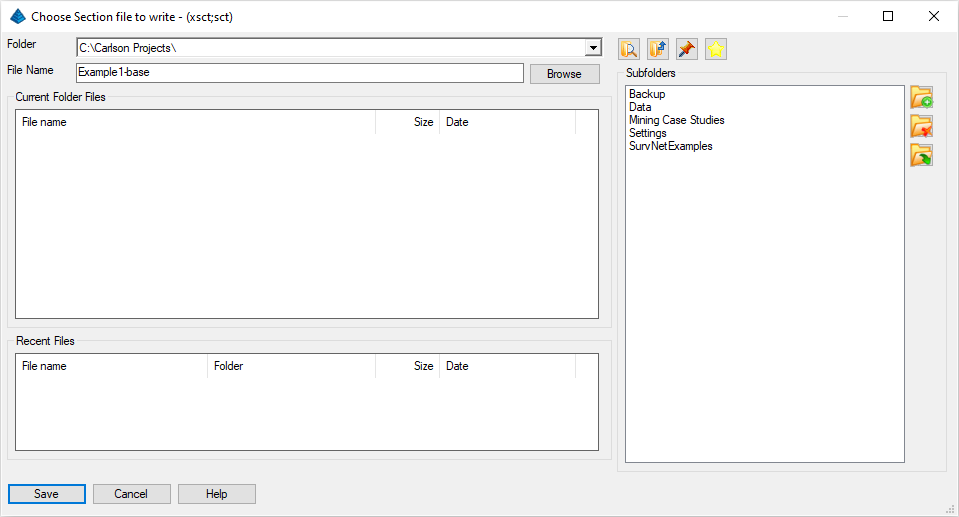

Choose Section File to Write (dialog):

specify a file name as illustrated below and

click Save when ready

The first of two section files is written.

- Let's follow the same general process for the

Final (pile) surface with a few minor adjustments.

Re-issue the Sections -- Create Sections from... --

Sections from Grid or Triangulation Surface

command. When prompted:

Choose Grid or Triangulation file to Process

(dialog): specify the pile.tin created earlier and click

Open when ready

Section Options (dialog): set the option to Prompt and click

OK when ready

Section Alignment File to Process

(dialog): specify the section alignment

(*.MXS) created earlier and click Open when

ready

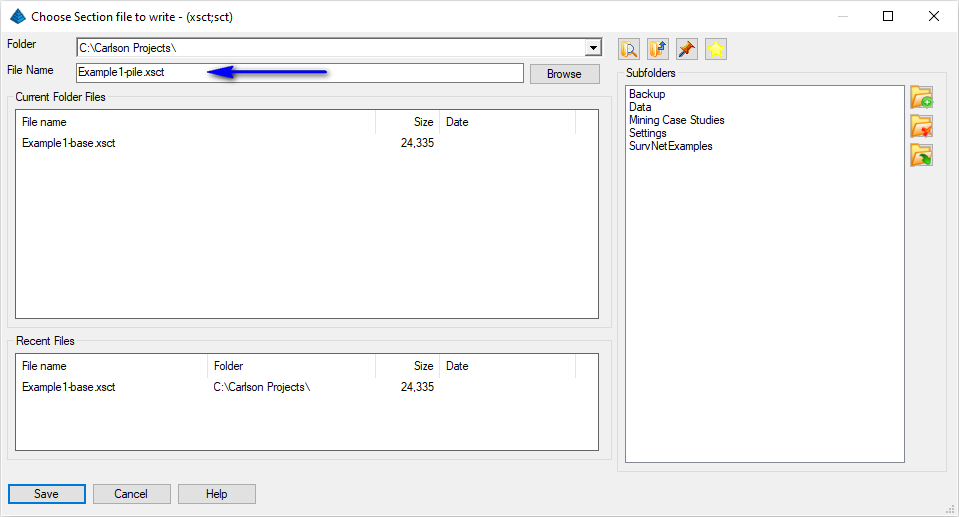

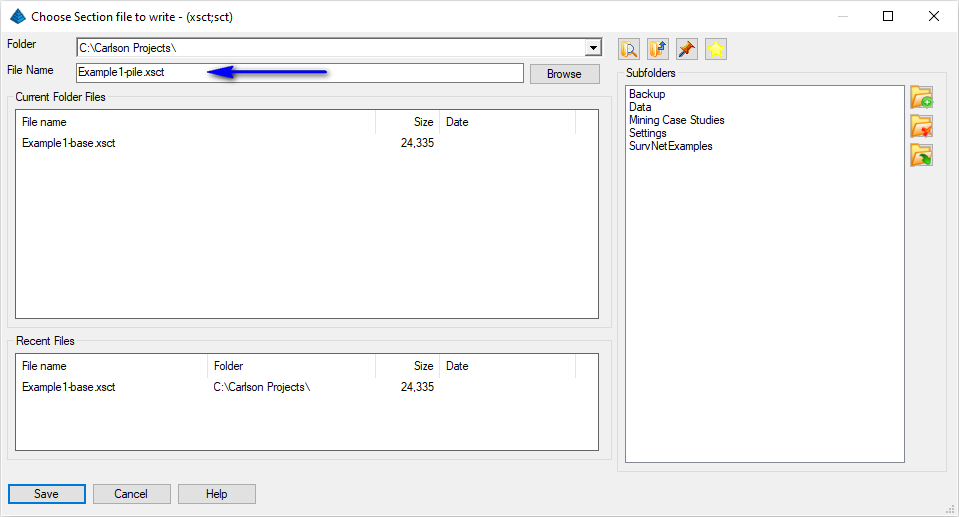

Choose Section File to Write (dialog):

specify a file name as illustrated below and

click Save when ready

The second of two section files is written.

- Optional: Similar to the Check Surfaces (grid) and the Check

Surfaces (TIN) steps discussed earlier, this is an optional

step to check that the section(s) are correct. Issue the Sections

--

Section File Editor command and when

prompted:

Section File to Process (dialog):

select the pile section file

that was just created and click Open when

ready.

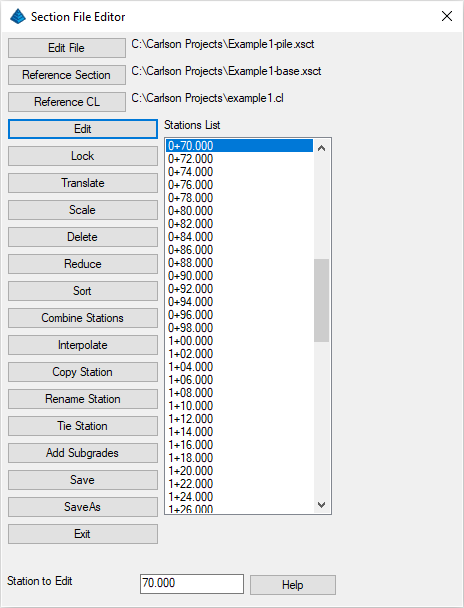

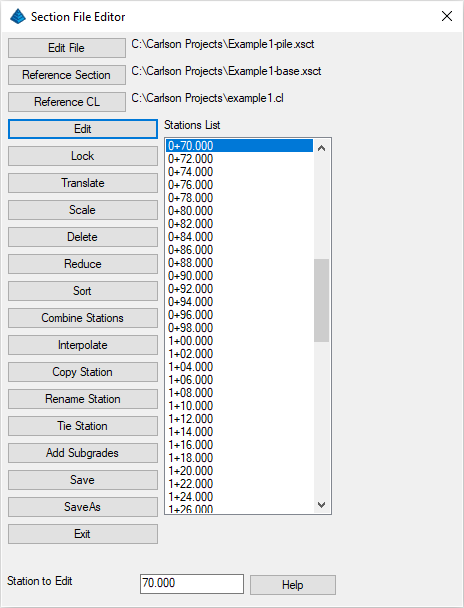

A Section File Editor dialog box similar to that shown below

appears:

Set the remaining values as shown above. To examine a specific

section, scroll through the list and select a desired station

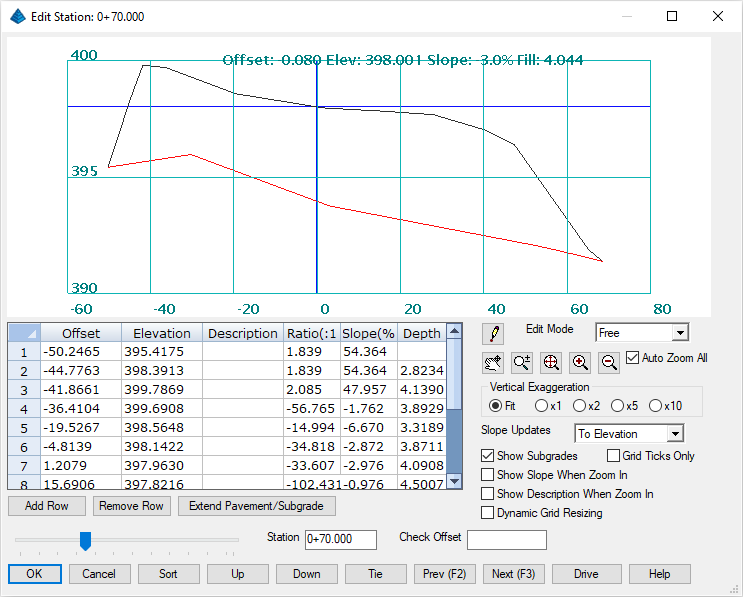

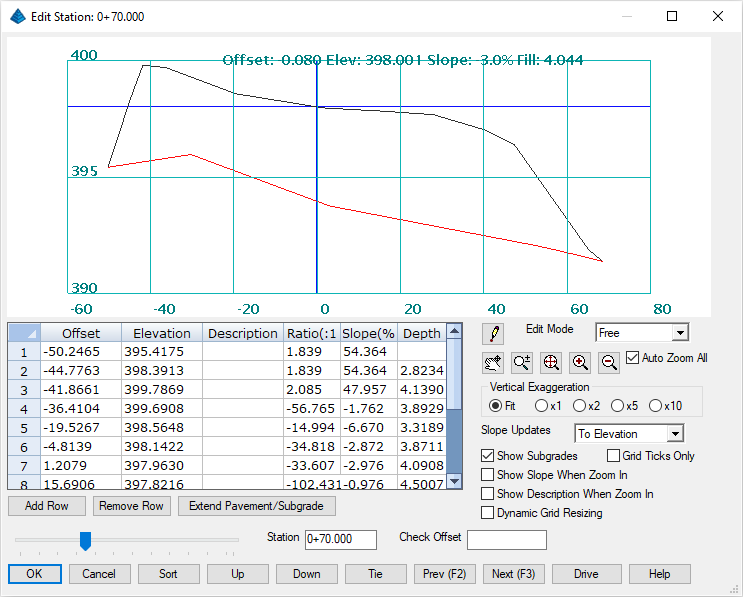

(e.g. 0+70.00) and click the Edit button

to display a dialog box similar to that shown below:

Review the controls in this dialog box and click

OK when ready and then click Exit

on its parent dialog box.

- Now that we have two section files, we can derive the volume

between them. Issue the Sections --

Calculate Section Volumes command. When prompted:

Section File (Existing Ground) to Read

(dialog): select the Base

section file and click Open when

ready

Section File (Final Ground) to Read

(dialog): select the Pile

section file and click Open when

ready

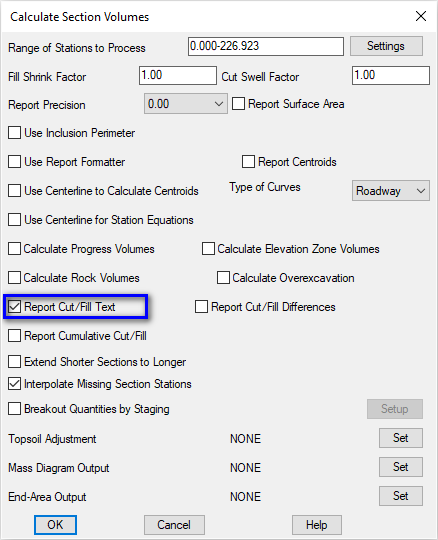

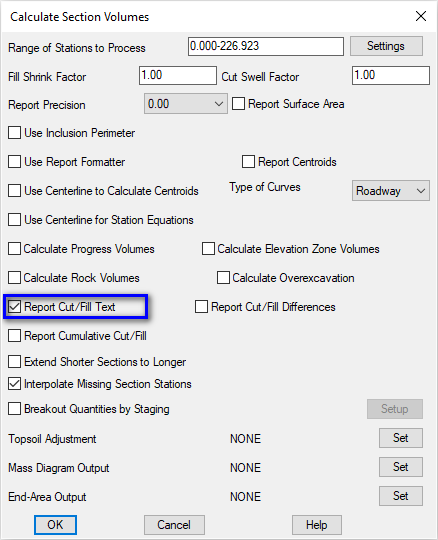

Calculate Section Volumes (dialog):

set the values as shown below and click

OK when ready

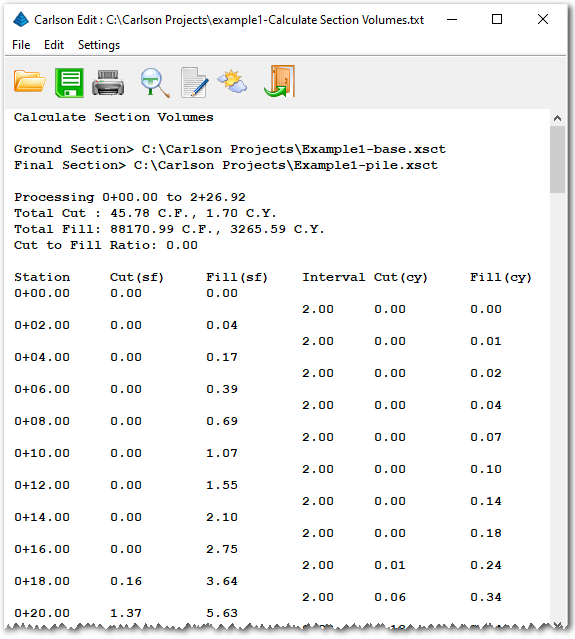

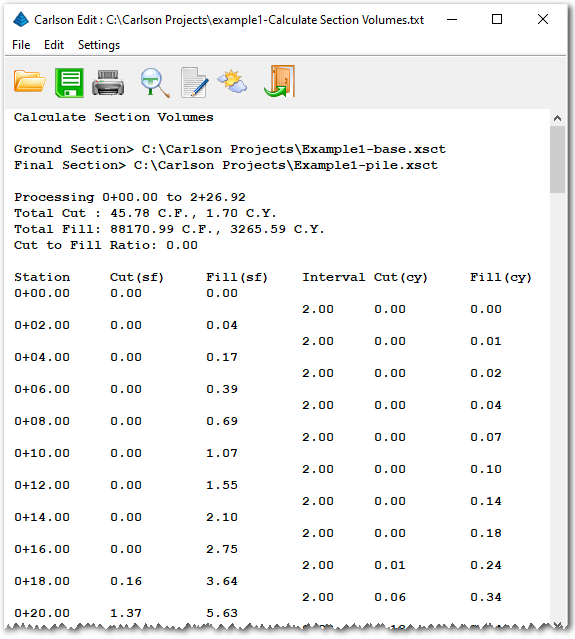

The volumes are calculated and reported, along with the cut and

fill end-areas at each station as illustrated below:

Review the results and click the Exit (Doorway)

button to dismiss the report.

Results Summary

As mentioned earlier, each volume methodology has a particular

use and knowing the application(s) for each method will serve you

well. Here is a summary of our results:

Volume Summary/Comparison

| Method |

Fill (c.y.) |

Cut (c.y.) |

When to use |

| Stockpile Volumes

|

3,264.22 |

- na - |

Quick and approximate Fill-only volumes are sufficient |

| Volumes By Layers

|

3,264.22 |

1.59 |

Quick and for large data sets when approximate Cut and Fill

volumes are sufficient |

| Two Grid Surface Volumes

|

3,264.60 |

1.61 |

Large data sets when approximate Cut and Fill volumes are

sufficient |

| Volumes By Triangulation

|

3,265.55 |

1.70 |

Large or small data sets when precise surface-to-surface Cut

and Fill volumes are needed |

| Calculate Sections Volumes

|

3,265.59 |

1.70 |

Corridor studies where end-area averages are sufficient |

This completes the tutorial: Calculate Volumes By Five

Methods.

Set the values

as shown above (click OK when ready) and when

prompted:

Set the values

as shown above (click OK when ready) and when

prompted: