The Unassigned Column lists all benches that have not yet been

assigned to a piece of equipment.

The benches shown in the 3D graphics window will be shown as

flat benches by default. However, benches may be associated with

elevation surfaces to show realistic dimensions via the Timing

Project Manager attribute groups. More information on this

feature is available in the corresponding section of the help

manual.

Vertical Scale: This value controls the vertical

exaggeration of the graphics window.

Color By: This drop-down list controls how benches are

colored in the graphics window.

The Bench Number option will color each bench level with

a color specified in the Set Bench Rules options.

The Grade option will color each bench according to a grade

parameter file. Any attribute in the pit may be used for grade

categorization.

The Destination option will color each bench according to

it's assigned destination. Note that destinations must be enabled

in the Timing Project Manager in order for this option to be made

available.

Control

|

Action

|

|

This control represents the position of the sun in

plan view. If the yellow square is in the center of the blue

circle, the sun is in a zenith. If the yellow square is near the

edge of the circle, the sun is near the horizon. To move the yellow

square, simply drag it to a new location, or click on the new

location. The slider bars on the sides control the intensity and

brightness of the display. |

|

Switches to Dynamic Zoom mode. Click and drag to

zoom in and out. |

|

Switches to Rotation mode. When the cursor is

placed near the outer edge of the view, a "Z" cursor is presented

that permits rotation around the Z-axis. When the cursor is placed

further into the interior of the view, an "X,Y" cursor is presented

that permits the tilt angle of the view to be adjusted. |

|

Switches to Pan mode. Click and drag to pan. |

|

Switches to Pick mode. When active,

double-clicking benches in the graphics window assign benches to

the equipment or destination based on the Pick Action

option. |

|

Prompts you to select linework such as contours or

3D faces to add to the 3D viewer window. This linework can be used

to identify reference points in the drawing to assist in pit

selection.

|

|

Toggle shading of Pits and 3D Faces. |

|

Exits the 3D Pick window, calculates the amount of

time required to mine the assigned benches, and generates a report.

This function is discussed later in this section of the help

manual. |

|

Displays a detailed report of the current timing

assignment. This is similar to the standard Report function, but

provides more detailed information and does not attempt to create a

timing map. An example report is shown below.

The calculator icon at the top left of the screen

will recalculate the timing results of the currently assigned

benches. This allows additional pits to be added/removed from the

assigned equipment and then quickly recalculate the impact on the

scheduling.

The spreadsheet report will display benches to be mined in the

currently selected time period.

|

|

Controls the information displayed on the bar

charts. When clicked the below dialog will appear.

This dialog contains two columns: Available and Used. Only items

in the Used column will be shown in the Quantity and Qualities

chart. Items may be moved between the two columns by selecting the

item and clicking one of the green arrows between the two columns.

To the right of the Used column are four icons. The green arrows

can be used to move the selected item up and down in the list. The

red pencil can be used to edit the selected item as described

below. The blue reset icon will clear out all used attributes and

return them to the available column.

When an item is first moved to the Used column, the below dialog

will appear to control that item's appearance on the chart,

including minimum value to display, maximum value to display, and

color. If destinations have been enabled in the pits, you will be

able to define charts for each grade of material according to the

grade parameter file used to color the pits by Grade.

Total Method: This drop list controls how

the attribute will be totaled. For volumes/tonnages, it is most

sensible to simply Sum the parts to calculate the total, whereas

quality attributes often need to be calculated as a Simple Average

or a Weighted Average. When using the Weighted Average option, you

will be able to use another attribute for weighting.

Enable Targets: This option will simply draw two horizontal

lines across the bar charts, according to the Target Max and Target

Min values.

Create/Edit Equation: These buttons allow you to create/edit

new equations to display in the bar charts (and the tooltip). These

equations are the same as those available in the

Define Equations dialog. |

|

Controls the attributes that are displayed in the

tooltip when the cursor is hovering over a bench. Attributes in the

left column will not be displayed.

|

|

Undoes the last pit(s) selected in the 3D pick

window.

|

|

Zooms to the extents of the items shown in the 3D

window.

|

|

This icon will only be shown when destinations have been enabled

in the Timing Project Manager. When clicked, the below dialog will

appear. Here you can define various destinations and assign a

color. Destinations may be be added/removed with the plus/minus

icons, and reordered with the up/down arrows.

|

|

This icon will only be shown when destinations

have been enabled in the Timing Project Manager. Clicking this

button will prompt you for a grade parameter file. Benches will

then be automatically assigned to their various destinations based

on the grade of the material. Please note that the color assigned

to the grade category in the grade parameter file must match the

color of a pit destination. If no match is found, the bench will be

assigned to the first destination in the above list.

|

Ignore zero elev: This option will toggle the visibility

of surface features at zero elevation in the graphics window.

Pick Mode: This drop-down list controls how benches are

assigned to equipment. When the Single Pick option is selected,

benches will be selected one at a time by double-clicking on each

bench. When the Multi Pick option is selected, multiple pits may be

assigned by double-clicking the first pit in a line to be mined,

then double-clicking the last pit to be mined. Once two pits have

been selected, they may be assigned to the equipment by

right-clicking anywhere in the graphics window. Additional lines of

pits may be added with additional double-clicks.

Use Rules: This option will apply the bench rules when

selecting benches. These option can be defined with the Turn

Benches On/Off icon.

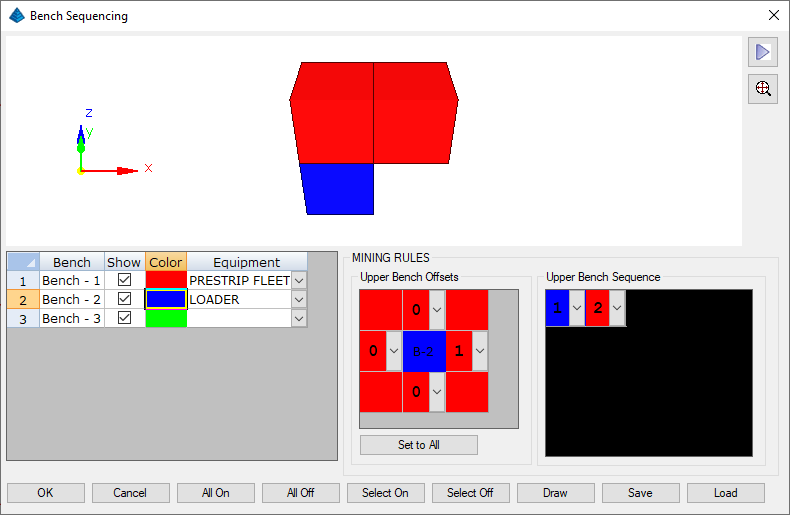

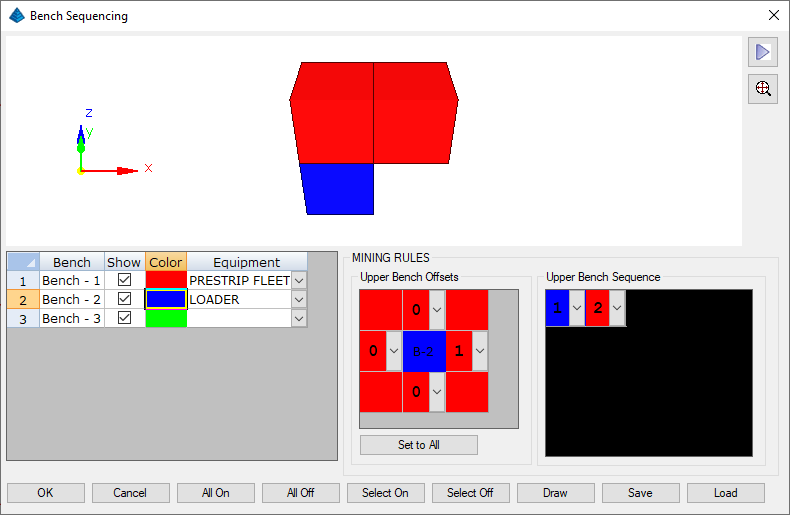

Set Bench Rules: This button will open the Bench

Sequencing dialog, shown below. This is intended to assist with

sequencing when using the Single Pick option of selecting benches.

When a bench is selected for mining, other benches will be

automatically selected based on these bench rules. Note that in

order to use the Bench Rules, pits must be oriented in the N-E-S-W

directions. If the pits are not naturally oriented this way, the

Twist Screen command may be used (prior to executing the Surface

Equipment Timing command) to align the pits in the N-E-S-W

directions.

The Graphics window at the top of this dialog will show an

example of the bench rules to be applied.

The List of Benches on the left side of this dialog controls

various options for the benches.

The Mining Rules on the right side of this dialog control the

automatic sequencing of the benches.

Bench Column: This column lists the benches in order from

top to bottom.

Show Column: This column controls if benches are shown in

the graphics window.

Color Column: This column controls the color of each

bench. Double-clicking one of the color cells will open the CAD

color palette for color selection.

Equipment Column: This column controls which piece of

equipment the bench will be assigned to. If no equipment is

specified, the benches will be assigned to the current equipment

selected on the 3D pick dialog.

Upper Bench Offsets: This graphic controls how many

benches should be developed in addition to the bench that is

actually selected in the 3D Pick dialog. The center square

represents the bench that is selected in the 3D pick window. The

numbers on each side of this square control how many upper-level

benches must be sequenced in addition to the selected bench. In the

above image, anytime a bench on level-2 is selected for sequencing,

the bench on level-1 just to the east will also be sequenced. These

benches will be assigned to the equipment specified in the

Equipment Column.

Upper Bench Sequence: This graphic controls actual

sequencing of the automatically sequenced benches. In the above

image, the upper bench (red) will be mined first, then the level 2

bench will be mined.

Set to All: This button will apply the current bench

sequencing rule to all other benches. For example, if a rule is

defined for level 2 to mine one bench to the east on level 1,

clicking this button will apply a similar rule to lower

benches.

All On/Off: These buttons will toggle the "Show" option

for all benches.

Select On/Off: These buttons will toggle the "Show"

option for the currently selected benches.

Draw: This button will draw a preview of the selection in

CAD. Picking a bench will fill in that bench with a yellow hatch.

All other benches to be automatically sequenced along with this

bench will be outlined with the same Bench Color. In the below

example, Pit 1-3 Bench 2 has been picked for scheduling, and Pit

1-4 Bench 1 has been outlined to show that it will be automatically

sequenced.

Bench Sequence Rules Example:

The below images show the bench rules for a 3-bench example. In

this example, whenever a level-2 bench is selected, up to 3 level-1

benches will also be sequenced. Whenever a level-3 bench is

selected, up to 3 level-2 benches will also be sequenced. These

rules compound, meaning that whenever a level 3-bench is selected,

up to 8 level-1 benches may also be sequenced.

Using these bench rules, 5 benches were manually picked as shown

below. The yellow number, indicating the order of selection, lies

on top of the bench that was actually selected; all other benches

were automatically assigned to the appropriate equipment. The final

sequence applied to each piece of equipment is also shown below

this progression. This allows a total of 26 benches to be sequenced

by selecting only 5 benches. This can save tremendous amounts of

time when working with multi-bench pits.

Pick Action: This option will only be shown when pit

destinations have been enabled in the Timing Project Manager.

The Set Equipment option will assign benches to the

current equipment.

The Set Destination option will assign the destination of

the selected bench.

Pick Destination: This option will only be shown when pit

destinations have been enabled in the Timing Project Manager and

when the Pick Action is set to Set Destination. When shown,

any benches selected will be assigned to the currently selected

destination.

Pick Equipment: This drop-down list includes all

equipment that have been added to the main Surface Equipment Timing

dialog. Benches will be assigned to the selected equipment.

Blocks Assigned To Selected Equipment column: This list

shows all benches that have been assigned to the selected

equipment. The benches are listed in the order they will be mined.

The green arrows to the right of this list will move the currently

selected bench up and down in the list. The green X to the right of

this list will remove the selected bench from the list and make it

available for assignment to another piece of equipment.

Bar Charts: The charts at the bottom of the dialog show

the quantities and qualities of the pits assigned to the current

piece of equipment. As benches are assigned to a piece of

equipment, the charts will dynamically update. The appearance of

each chart is controlled with the Chart Settings icon, as discussed

above. Each chart may show multiple vertical bars, with each bar

representing a period of one or more pits. Periods may be defined

manually or automatically. It is important to note, however, that

the periods that define these charts are only temporary tools for

inspection - these periods will not be used in the final timing

report. It is important to note that the bar charts are intended to

be a short-term inspection tool. The bar charts will not be saved

when you exit the 3D Pick window.

Maximum Bars: This value controls the maximum number of

periods (and thus, the number of vertical bars) that may be shown

in each chart.

Timelapse: This checkbox will create a new period each

time a bench is selected, thus adding another bar to the charts.

Once the maximum number of periods is displayed, older periods will

be removed from the charts. You will need to click the Reset Charts

button before this option can be disabled.

Chart Unpicked: This option will reset the charts and

only show information pertaining to benches that have not yet been

assigned to a piece of equipment.

Display Assigned Blocks: This option will display timing

blocks that have already been assigned to a piece of equipment. The

blocks will display with a transparent gray color to indicate they

have been assigned. When this option is enabled, selecting a pit in

the "Blocks Assigned to Selected Equipment" list will highlight

that block with a yellow color. With this option, you can quickly

review the progression of blocks that have already been assigned to

a piece of equipment.

Period Slider Bar: The slider bar below the charts is

only available when the Timelapse option is disabled. This slider

bar allows you to control how many benches are represented in the

last vertical bar of the charts. For example, if the slider bar is

moved to the right end of the bar, all assigned pits will be

represented in the last vertical bar chart. If the slider bar is

moved closer further to the left, then fewer pits will be

represented in the last vertical bar chart.

Manually Mark End of Period: This option is only

available when the Timelapse option is disabled. The slider above

this button controls which benches are in the current period. When

this button is clicked, the current period will end and a new

vertical bar will be added to the charts. You may then repeat the

process to create additional periods. This allows you to compare

attributes for multiple periods, thus showing, how the quality of

the material mined will change over time. When manually marking the

ends of the periods, none of the benches from a previous period

will be considered in the new period.

Automatically Set Period by Interval: This button will

define periods according to a set value. The pulldown menu to the

right of this field controls which attribute is to be used for the

definition of each period. For example, if this option is set to

mark periods at 10,000 Key Ton intervals, the program will

determine how many benches are needed to hit that target. Each time

the value is exceeded, a new vertical bar will be added to the

charts. It is often useful to reset the charts before using this

option.

Reset Charts: This button will clear the charts.