This command models pressure pipe networks using methods and computations as required by the U. S. Environmental Protection Agency and compatible with EPANet software (version 2.2). This network, while using a .util file extension for data storage, is a separate model from utility or sewer networks. A pressure pipe network is made up of water source reservoirs, pumps, pipes, valves, water demand and storage tanks defined by horizontal and vertical alignment (centerline and profile), and parameters associated with the features of the network. The pressure pipe network models can be used in the Collisions Conflict Check command along with sewer and utility network models.

The top of the docked dialog box has thirteen

buttons. Hover over each icon to see its name. Each button is

described as follows:

The Edit button edits the highlighted element from the

pressure pipe network.

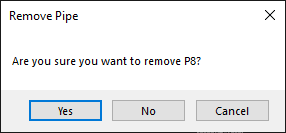

The Remove button deletes the highlighted element from

the pressure pipe network. If a valid element is selected, then you

will be prompted to verify the element removal with the following

dialog:

The Report button displays the Report dialog box.

The Data Files Report displays the files and parameters for

each component of the pressure pipe network.

The Min Cover Check Report displays the Reference Surface

and .util files used, and, for each pipe, the minimum cover as well

as the average cover elevation.

The Quantities displays the Carlson Report Formatter,

allowing the user to create custom reports using pressure pipe

network information, import additional information, present the

information in a variety of different formats, and export the

report for other use.

The Output IFC File button creates a file that can be used by other software to import the 3-D model of the pressure pipe network.

The Pressure Pipe Network Settings button displays

a multi-tabbed dialog box, defaulting to the "General" tab. All

pressure pipe network settings from all tabs can be saved to a file

using the SaveAs button. The saved settings are stored in a

.uns file. Any previously stored settings can be loaded using the

Load button. The new settings will not be stored into the

.util file until you press the Save

button on the main docked dialog.

The Reference Surface is a triangulation file that is

used for the min cover calculations and as a reference when editing

pressure pipe profiles. The Auto Zoom to Current

Selection check box finds and zooms to the component

highlighted in the pressure pipe network tree. Highlight

Current Centerline provides visual choices for in-drawing

indication of the pressure pipe network component which has been

selected.

On the "Plan View" tab, the Text and Symbol Size

Scalers are used to set the size of pressure pipe network text

and symbols for the Draw Plan View function. Clicking the

"Set" button next to the Text Style field controls the font

used for the pressure pipe network. The Label Name

dropdown box allows the user to place the pressure pipe network

component label at either end, at intervals defined in the Label

Interval field, or choose "None" for no labels on

components. Clicking the "Set" button beside The

Pump, Tank, and Reservoir Symbols, selects the 2-D plan view

symbols used for these components.

The Help button displays this document..

Clicking the Draw button displays the Draw dialog

box.

The 3D Polylines function creates a 3D polyline for each pressure pipe line. These polylines are tagged with their pipe size in the same format as the Assign Pipe Data to Polyline command.

The 3D Faces function draws each pressure pipe line as a 3D pipe using 3D faces. These 3D faces can then be used in the 3D Viewer commands.

The Plan View function draws a 2D polyline for each pressure pipe line and labels the line with its' name and connection points.

The Profile function displays the Select Profiles to Draw dialog box.

Set Reference Centerline allows the selection of a

Centerline file to choose a Profile file. Add allows

the selection of a Profile file. Add Multiple allows the

selection of more than one Profile file choice at a time.

Remove deletes a Profile from the list. Clear

removes all Profiles from the list. Special Stations

allows Station marks and elevation information to be displayed at

other positions on the profile than at the beginning, end, and

connection points by adding a new Station. Save Set

saves the list of profiles to a user defined file name for

recall. Open Set opens a previously saved Set.

Multiple Profile allows the manipulation of Profile files

containing more than one Profile.

Selecting the EPANet button displays EPANet Actions dialog box and defaults to the "Hydraulics" tab.

The Analysis Method dropdown box allows the selection

of one of three methods supported by EPANet.

The Units dropdown box allows the selection of the desired

volume per time unit.

The 2D Junction Tolerance allows the user to insert a 2D

distance. Like pressure pipe network entities within the 2D

tolerance will be joined even if the 3D elevation does not exactly

match.

EPANet Times Tab

The "Times" tab allows setting parameters for either a single time

period or an extended analysis.

If Time Period Analysis - Single is selected, all other

fields on the tab are deactivated, setting up a "snapshot" analysis

of the pressure pipe network.

If Time Period Analysis - Extended is selected, all fields

on the tab are available for edit. Total Duration is

the total length of time to be analyzed. Water quality is not

currently being analyzed in Carlson 2019. Quality Time

Step is not currently used. Pattern Start Time is

the time the Demand Patterns created and listed on the

"Demand Patterns" tab starts. Report Start Time is the first

time shown on the analysis. Hydraulic Time Step is the

time unit incremented as the analysis proceeds through the

Total Duration. Pattern Time Step is the time unit

used to step from one Demand Pattern to the next.

Reporting Step Time defaults to the Hydraulic Time

Step unless and different increment is assigned in this

field. Clock Start Time is when the analysis

begins. The Statistic controls how information is

presented in the Analysis report. None reports

data at each Reporting Time Step increment or, if zero, the

Hydraulic Time Step. Average reports the

average values found for the Total Duration.

Minimum reports the minimum value, Maximum reports

the maximum value and Range reports minimum and maximum

values across the Total Duration.

The "Demand Patterns" tab allows the weighting of water demand

assigned to connections and laterals when creating the pressure

pipe network based on time of day.

Select an existing pattern to be used to weight the demand during

different times of the day. To add a new Pattern, pick the

Add button. Another dialog is shown to enter the parameters. Type a

new Pattern ID, a new Description, desired

Multipliers and click OK.

In the example above, the Clock and the Pattern start at midnight

and the demand is reduced by the Multiplier 0.50 until the

Pattern Time Step increment comes due at 6am, increasing the

demand by 1.3. At noon, demand drops to its' default values,

then at 6pm demand is increased by a factor of 1.20. Note

that the Pattern Time Step and the number of

Multipliers are synchronized.

Add/Edit EPANet

Curves

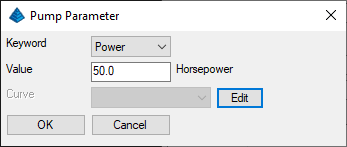

Next, develop a pump curve by clicking the Curve button. By

specifying the Type, the values in the X and Y columns are

defined.

The Curve Type Pump develops a single-point or multi-point

Pump Curve plotting volume per unit time (flow rate)

in the X column, head in the Y column. An Efficiency Curve

plots a pump's flow rate in the X column vs. energy use efficiency

as a percentage in the Y column. A Volume Curve plots

flow rate in the X column vs. the change in elevation (head) in a

tank and is used to model tanks with non-uniform cross

sections. A Headloss Curve plots the flow rate in the

X column vs. the headloss in feet or meters in the Y column as

water flows through a General Purpose Valve.

The Analysis button produces a report that can be viewed,

saved, printed and search showing demands, flow rates, head, energy

consumption, pressures, velocities and headlosses in the Network,

either as a snapshot or with a Demand Pattern applied.

The Export button creates a file which can be imported into

EPANet.

The Save button saves any changes made to the current

.util file.

The SaveAs button prompts for a new .util file and saves the current pressure pipe network and settings .

| Converted from CHM to HTML with chm2web Standard 2.85 (unicode) |