Underground Timing

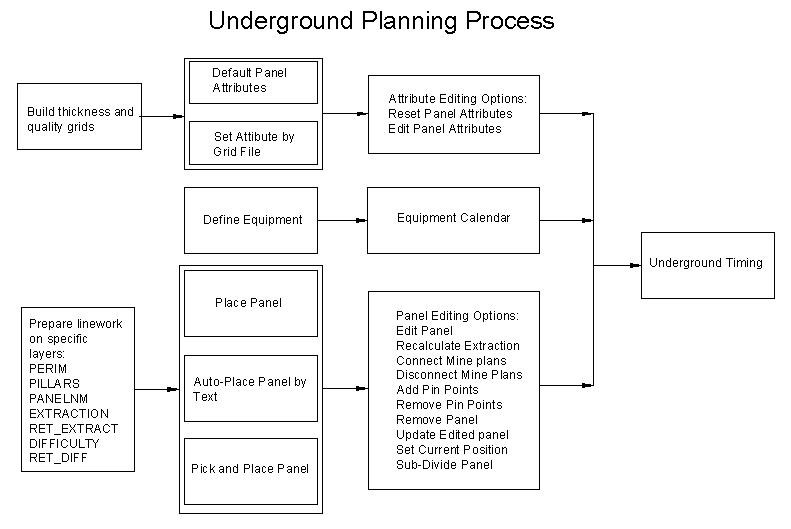

The diagram above shows the general steps associated with the

creation of a mine plan with the Underground Timing routine.

Prerequisites include:

- Creating thickness, density, and quality grids, and/or average

values for the total coal and rock to be mined.

- Define the productivity rates of the equipment and operating

schedule for each section of equipment.

- The drawing linework has to be prepared on specific

layers.

- Panels can be placed using one of, or a combination of, three

placing routines: Place Panel, Auto_Place Panel by Text, and/or

Pick and Place Panel.

- Several adjustments to the mine plan can be by Adding Pin

Points, Recalculating Extraction, Connecting Mine plans, and

Editing panels.

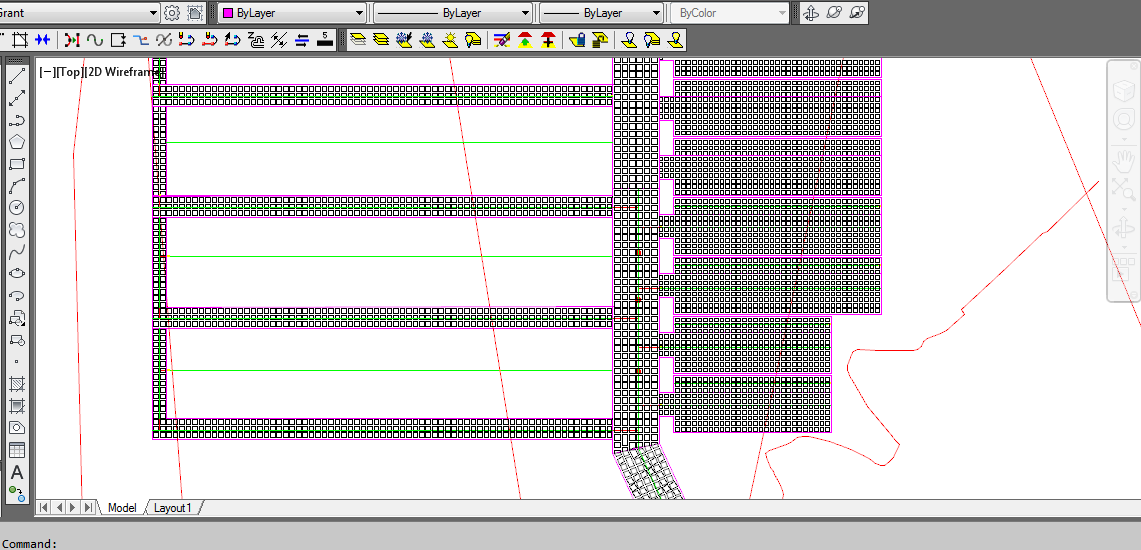

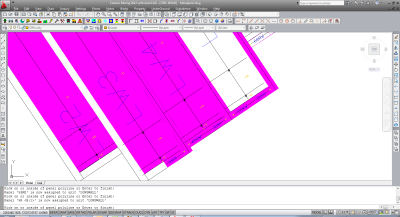

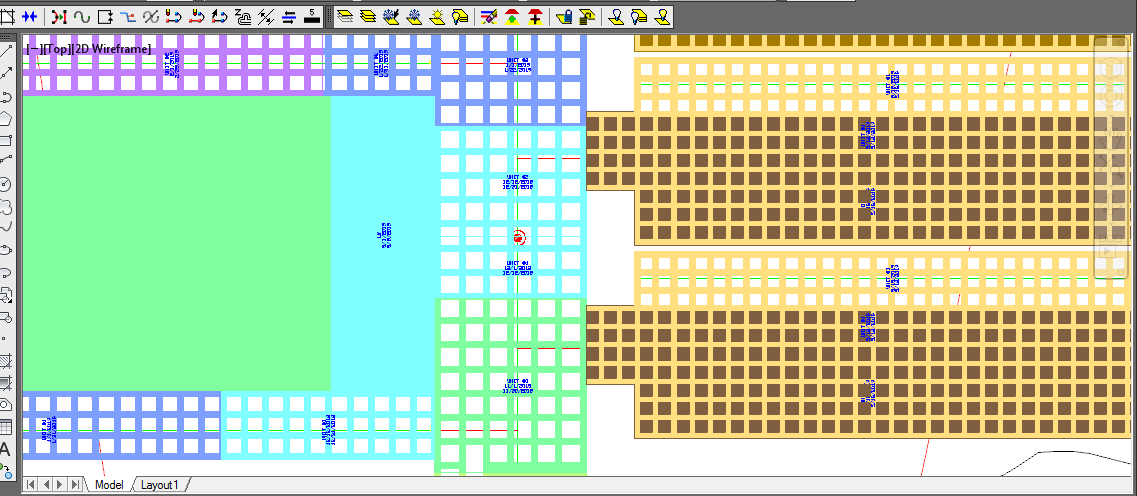

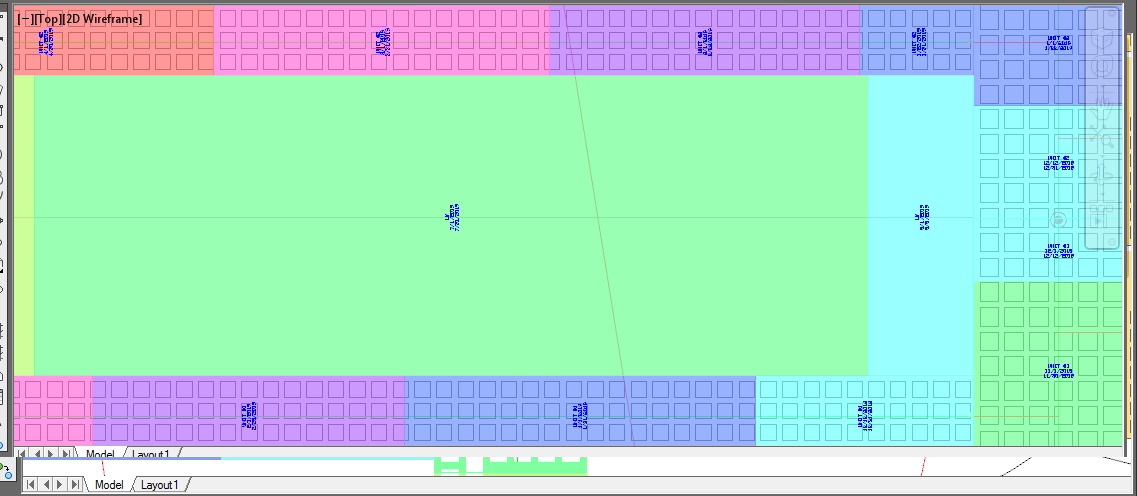

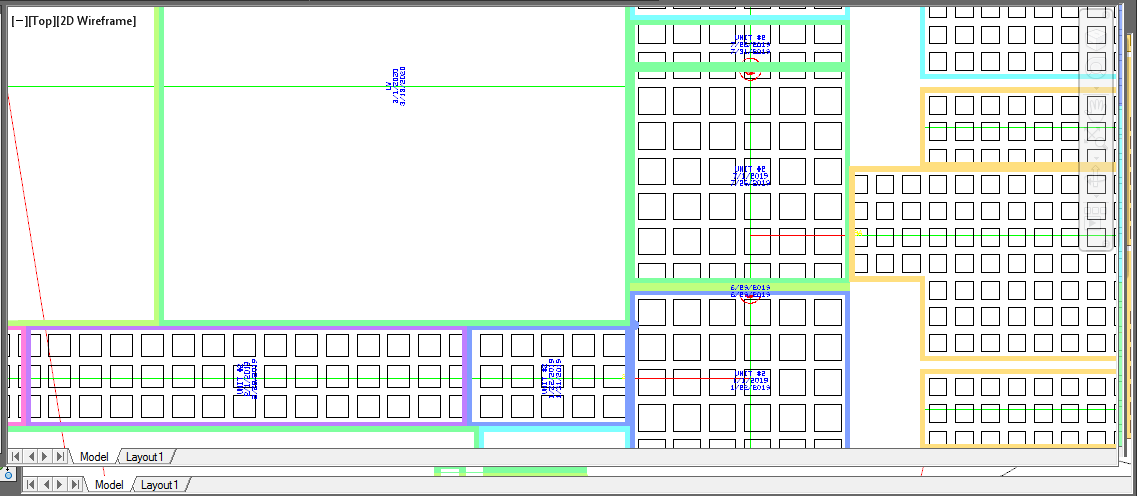

The drawing above shows a simple mineplan layout of longwall

and continuous miner panels. The panel perimeters are drawn

on the PERIM layer, and the pillars are on the PILLARS layer.

The panels in this example were placed using Pick and

Place.

The drawing above shows a simple mineplan layout of longwall

and continuous miner panels. The panel perimeters are drawn

on the PERIM layer, and the pillars are on the PILLARS layer.

The panels in this example were placed using Pick and

Place.

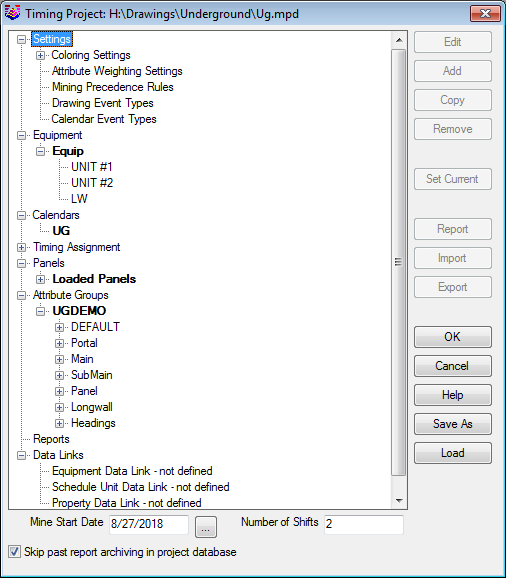

The Mining

Project dialog box above shows some of the key files used in the

mine timing. Options on the right side become active

depending on the items selected on the left side.

The Mining

Project dialog box above shows some of the key files used in the

mine timing. Options on the right side become active

depending on the items selected on the left side.

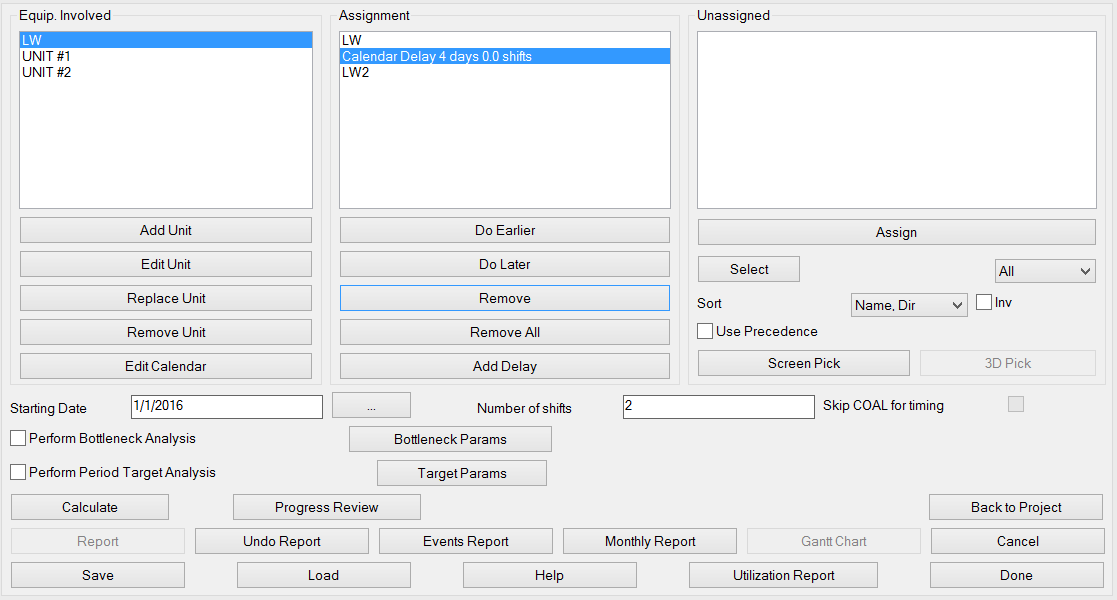

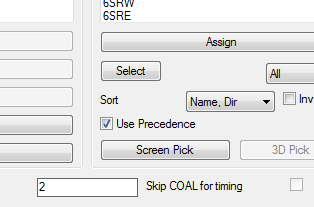

The Underground Timing dialog box provides options to assign panels

to be mined to the equipment, insert delays between panels, input

the plan start date, number of shifts/day, and undo the current

report. Disregard the bottleneck options for underground mining, as

this is intended for the Surface Equipment Timing command.

The underground timing routine calculates the time needed to

complete the assignment, calculates coal quantities and qualities,

draws results period by period, and produces a production report.

In order to calculate timing, every panel needs to be assigned to a

piece of equipment. The left list box shows the available

equipment. Use the Add Unit button to create a new piece of

equipment or edit to change the definition of the defined

equipment. This list is stored within the mine plan and is

different for every plan. The Edit Unit button calls the same

dialog as the Define Equipment function.

The middle list box shows panels currently assigned to the

equipment highlighted in the left list box (if any). To assign a

panel to the equipment, first click on the equipment name, then on

the panel name in the right list box and at last on the Assign

button. Panels are mined in the same order as they appear in the

list. To complete mining of all assigned panels successfully, the

order should not be controversial (i.e. NMAINS <1:2> cannot

appear before NMAINS <B:1>). To change sequence of mining

click on the desired panel name and use the Do Earlier or Do Later

buttons to change the order. The Remove button removes the

highlighted panel from the list of the panels assigned to the

current crew and moves it to the right list box. Use the Add Delay

button to add a delay (for moving of equipment, maintenance or

other reason) after the highlighted panel. After all panels for the

first piece of equipment have been added, you may repeat the

process for each piece of equipment until all the needed panels are

properly assigned.

The Use Precedence option will apply the settings defined in the

Mining Precedence Rules under the Settings of the Timing Project

Manager.

Screen Pick will allow you to assign panels to equipment by

actually selecting them on the screen. Each panel is hatched with a

solid fill to give instant feedback that the panel has been

assigned. If pin points are in the panel, it will only hatch up to

the next pin point, allowing the panel to be assigned in order as

separate entities.

When the assignments are complete, click the Calculate button.

Check the timing report produced and make sure that all assigned

panels have been developed. If the process terminates before all

panels are calculated, you may need to modify the assignment and

try recalculating the timing. During retreat mining it is possible

that a sub-panel will be completed later that the panel itself. If

this conflict occurs the calculation algorithm will try to offset

the start date of the panel itself to get timeout sufficient to

resolve the problem. In the case when a problem cannot be resolved,

an alert box with corresponding message will appear.

The time needed to develop a panel is offset by the Extraction

Ratio and Difficulty Factor defined in the Edit Panel Dialog, and

thickness and density of coal and rock defined by the Edit Panel

Attributes function. The presence of qualities in the production

report depends on the list of panel attributes and their values

defined by the Edit Panel Attributes function.

In cases when the mine plan includes retreat (second) mining, the

system will make sure that when the parent panel is mined on

retreat, the mining (advance or retreat) in all child panels is

completed. If not it tries to offset the starting date of retreat

in the parent panel until the timing conflict is resolved.

Sometimes it is impossible to do so and the program reports the

problem to the user for manual resolution.

The Skip COAL for timing option can be ignored for Underground

Timing, as this option is intended for Surface Equipment

Timing.

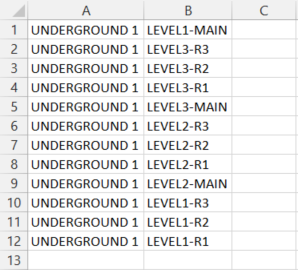

Once panels have been assigned to the various equipment, the

assignments can be saved to a .tim or a .csv file. Both can be

edited with a simple text editing program such as Notepad, but the

.tim format is not as user-friendly as the .csv format. When

exported to a .csv, you can very easily editing the timing

assignments in Microsoft Excel, then load the timing assignments

back into the Underground Timing dialog. In the .csv format, the

first column is the equipment name and the second column is the

panel name. An example of this file type is shown below:

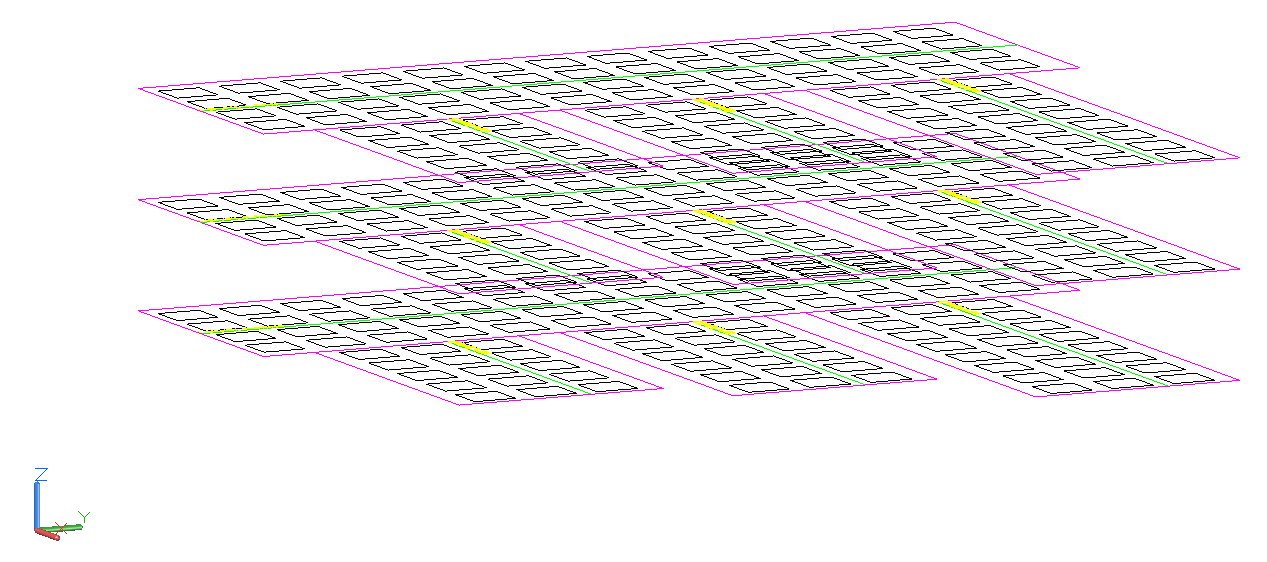

Multi-Level Mining

If a mine has multiple levels with similar panels stacked above one

another, a special set of layer names must be used when creating

the panels to allow for the distinction between levels. The key to

distinguishing mining levels is setting the linework on the correct

layer names, which must use a suffix similar to ‘_LEVELX’. For

example, the mine plan in the below figure has three levels. The

linework for the first level includes the following layers:

MINEPLTX, PILLARS_LEVELX, MINEPLAN, and PERIM_LEVELX. When

these panels were made using the Auto Place Panel by Text, the

panel name was on a layer named PANELNM_LEVEL1 and the panel

perimeter was on a layer named PERIM_LEVEL1. Levels 2 and 3 were

made in a similar fashion, but with the respective level name as

the suffix for each layer. Although it isn’t necessary, the

linework for each level in the below image has been drawn at a

specific elevation to allow for further visual inspection by the

3DORBIT command.

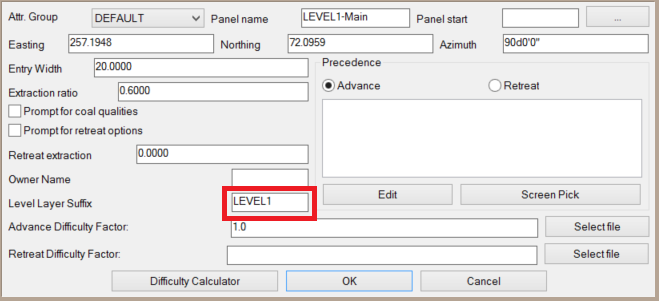

After the panels have been created, you may also inspect the mining

level via the Edit Panel command, which will allow you to enter the

Level Layer Suffix, as outlined in red below.

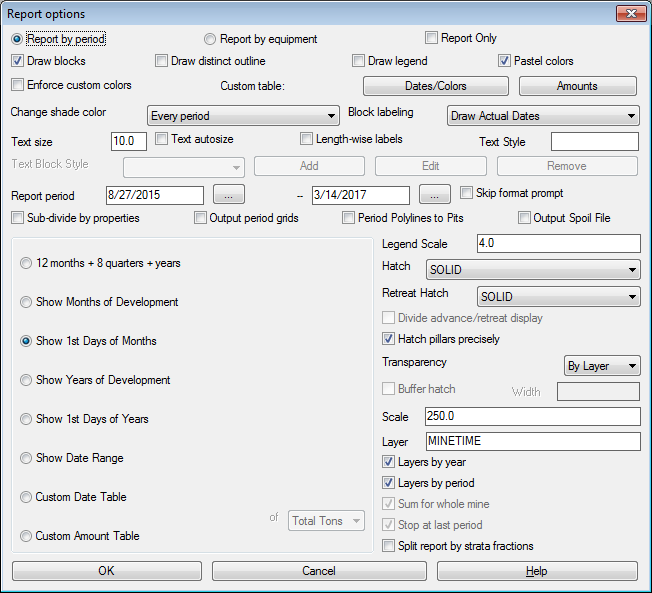

Report Options Details of each function are below.

- Report by period: This option is used to draw the

development progress period by period and to obtain quantities and

qualities report

- Report by equipment: This method is used to draw the

development progress by specific pieces of equipment, rather than

defining development by time period

- Report only: This option will skip the labeling and

coloring of the timing map. Instead, this option generates a

detailed text report. It usually runs much faster for quick

iterations

- Draw Blocks: Determines if the hatching and blocks are

drawn

- Draw Distinct Outline: Draws a perimeter polyline around

each timing period or equipment assignment area in the drawing

- Draw Legend: Draws a legend of the hatch colors and

periods/equipment

- Pastel Colors: Forces timing maps to be drawn in pastel

colors, which are lighter and generally use less ink when

plotting

- Enforce Custom Colors: This allows the use of any timing

period, in combination with the Custom Date Table defined colors,

hatches and layers for each period. The Dates/Colors options must

be set to use this option

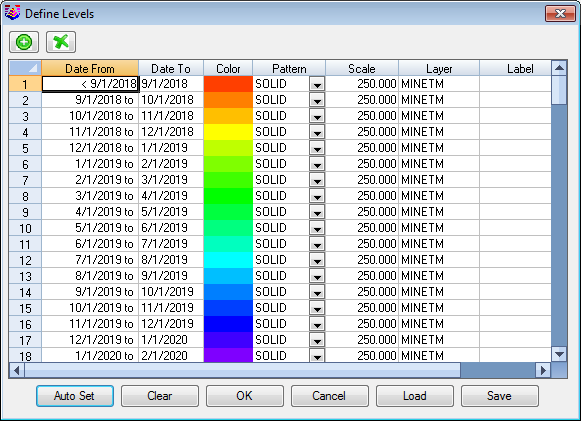

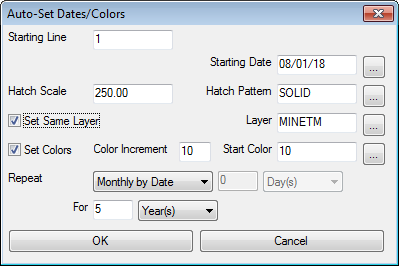

- Dates/Colors: The colors/dates table shown below defines

color/layer/label combination for a specific date range. The Auto

Set function may be used to fill out the table for repeating period

lengths starting at a particular line and to create a different

schedule later

- Amounts: When using the Custom Amounts option, the

amounts are defined here. They can have custom period names, or if

left blank it will automatically increment the periods

- Change Shade Color: Controls the increment by which the

hatch color changes. If set to ‘Every Period’, the color of the

hatch on the timing map will change for each new time period. If

set to ‘Every Year’, the color of the hatch on the timing map will

only change each year

- Block Labeling: There are options for No Labels, Actual

Dates, Period Names (short one word names), Custom Names (from

Custom Amounts and Dates/Colors tables) and Custom Text Block. The

Block is defined in the row below Text Block Style

- Text Size: Sets the size of the date text in the

blocks

- Text autosize: Changes the size of the text to fit in

the period blocks

- Length-wise labels: Rotates the period labels

horizontally

- Text Style: Sets the period labels text style

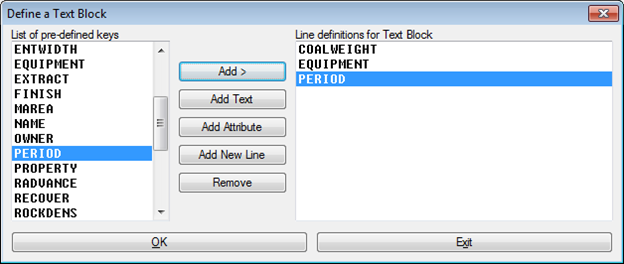

- Text Block Style: This defines any custom labels for

drawing in the period blocks. The blocks can be named and saved.

Fields to label appear on the left side and are moved to the right

for drawing. Buttons for Add, Edit and Remove the block are

here.

- Report Period: Sets the length of the period. If

the Show Date Range is on, the selected date range will be reported

as one period

- Skip format prompt: Skips over the Report Formatter, and

brings up the Display Text report, with the settings that were

previously defined

- Sub-divide by properties: Controls whether system uses

property lines and does calculations on per property basis per

period

- Output period grids: For Surface Timing, it this option

will write mine advance grids to a GSQ file, which can be used for

3D viewing of the mine progression.

- Period Polylines to Pits: Creates named pit boundaries

for each period. These can be used for other reserve commands.

- Output Spoil File: In Surface Equipment Timing, this

option creates a SPO file that is used for timing the backfill

dumps.

- 12 months + 8 quarters + years: Display monthly

development for one year, followed by quarterly periods for next 2

years, followed by yearly periods

- Months of Development: increments from the starting date

and continues from that date each month

- 1st Days of Months: increments from the 1st of every

month, even if the start date is not on the 1st. If not, then the

first month will be a partial month, and it resets to the first

after the first period

- Years of Development: increments from the starting date

and continues from that date each year

- Show Date Range: Displays a single period as specified

in the Report Period

- Custom Date Table: Completely user-defined sequence of

periods, with customized dates, colors, layers and hatches

- Custom Amount Table: When using the Custom Amounts, the

amounts are set here for amounts/period. The option ‘Sum for whole

mine’ determines whether the amount is a total for a whole mine or

just for each panel individually

- Legend Scale: controls the size of the legend

- Hatch: sets the hatch pattern for the mining

advance

- Retreat Hatch: sets the hatch pattern for the mining

retreat. It will either be split left and right of the centerline,

or hatch just the pillars

- Divide advance/retreat display: Draws the advance

coloring to the right of centerline and retreat hatching on the

left

- Hatch pillars precisely: Hatches just the entries on the

advance, leaving the pillars open. Then if there is retreat mining,

the pillars are hatched separately as they are retreat mined.

- Transparency: When using the SOLID hatch, this setting

controls the transparency of the hatch. The range is from 10%-90%.

This allows for viewing the entities behind the hatch, and for

plotting

- Buffer Hatch/Width: Another option for representing the

period blocks is with a buffer hatch. The width determines the

offset from the perimeter. It appears as shown here:

- Scale: Sizes the hatch pattern size

- Layer: Sets the layer for the blocks and perimeters for

the advance. The layer name for the retreat mining is prefixed with

"RT-" to the advance layer name

- Layers by year: Sets each year to a new layer for better

layer management and filtering

- Layers by period: Assigns each period hatch and

perimeter to its own layer

- Sum for whole mine: When using Custom Amounts, this

determines whether the amount is a total for a whole mine or just

for each panel individually

- Stop at last period: When using the Custom Amounts, the

timing will stop at the last defined period with an amount.

Otherwise it will continue to the end of the panels, repeating the

last entered amount

- Split report by strata fractions: If several named seams

make up the KEY, this option will divide output values by the

Strata rather than grouping values by pit

If the development progress is not satisfactory and the scheduling

needs to be adjusted, use the Undo Report button in the Timing

dialog to remove drawn report entities. After the dialog is

completed, the mining development is shown step by step and then

the production report is generated. The report format may be

modified to suite the particular need and preferred format saved

for further use. See HELP for complete description of Report

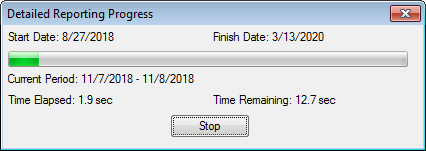

Formatting dialog. There is a progress window displaying the time

elapsed and the time remaining for large schedules that require a

lot of time.

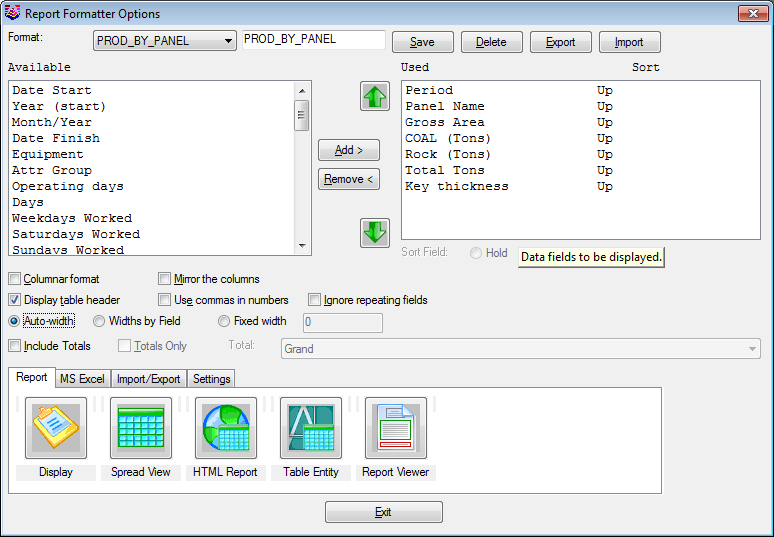

The Report Formatter has several output

options:

- Report: This outputs to an ASCII text file viewer

and an Ascii text file can be saved or inserted directly into

the drawing. Other reports are Spreadsheet, HTML, Tables and a

viewer.

- MS Excel: Exports the report directly to a Microsoft Excel

spreadsheet with many settings for cell formats and placement.

- Import/Export: Has several options to move data in and out of

your reports, and you can export to an MS Access mdb file as well

as others.

- Settings: Options here for editing attributes and attribute

options.

Report

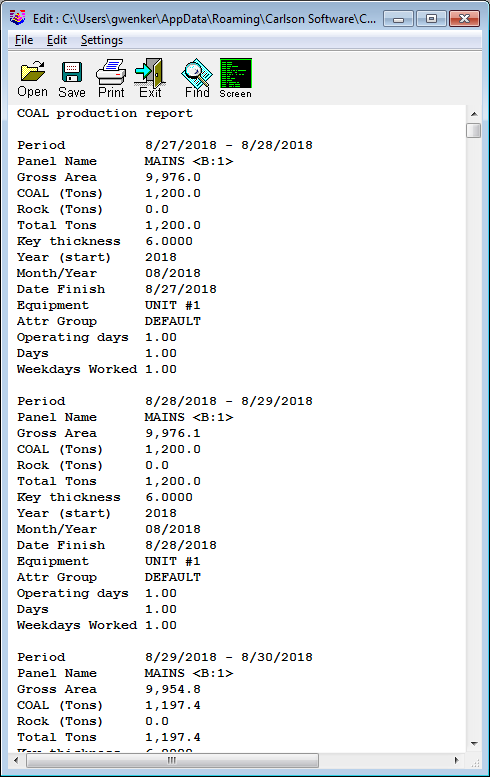

The Report tab outputs ASCII text reports as shown below:

The above report is an example of an ASCII text report in

Non-columnar format.

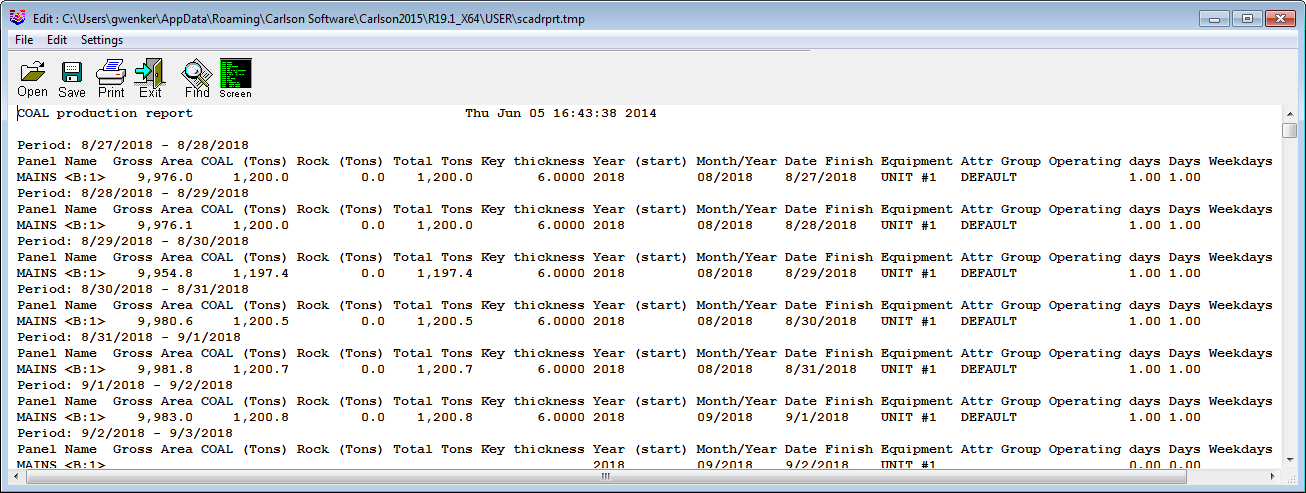

The above report is an example of a columnar ASCII text

report.

The report above is an example of an ASCII text report in a spread

view.

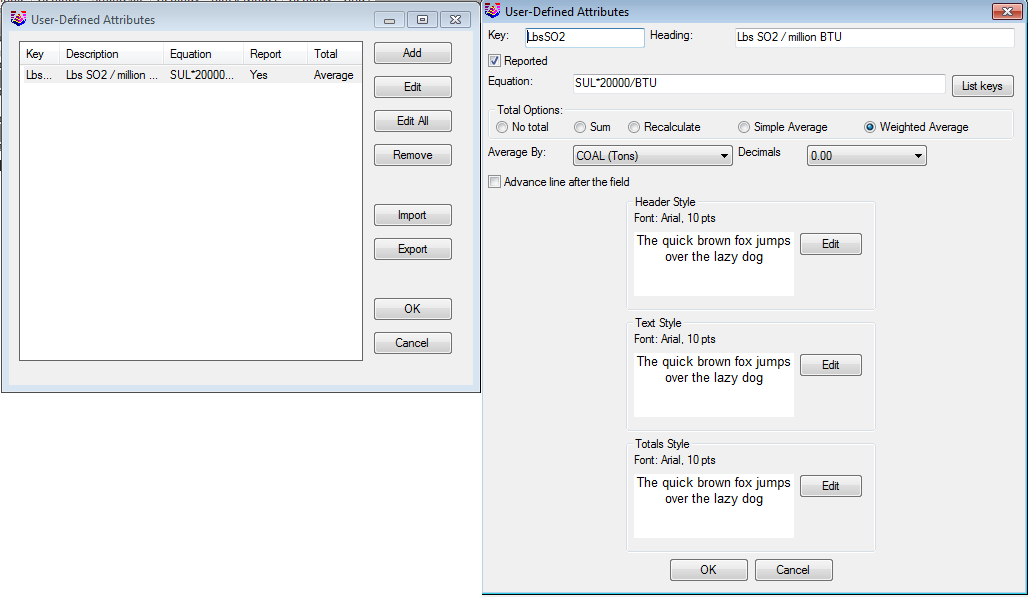

The User Attributes button under Settings leads to a dialog where

custom attributes can be created.

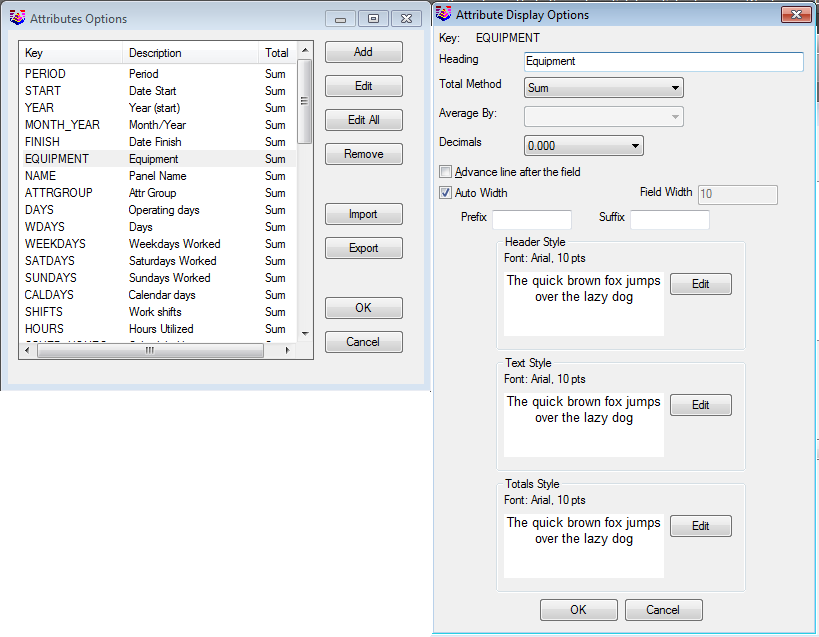

The Attribute options opens with a list of the attributes above,

providing display and formatting options below.

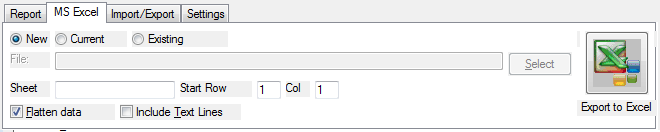

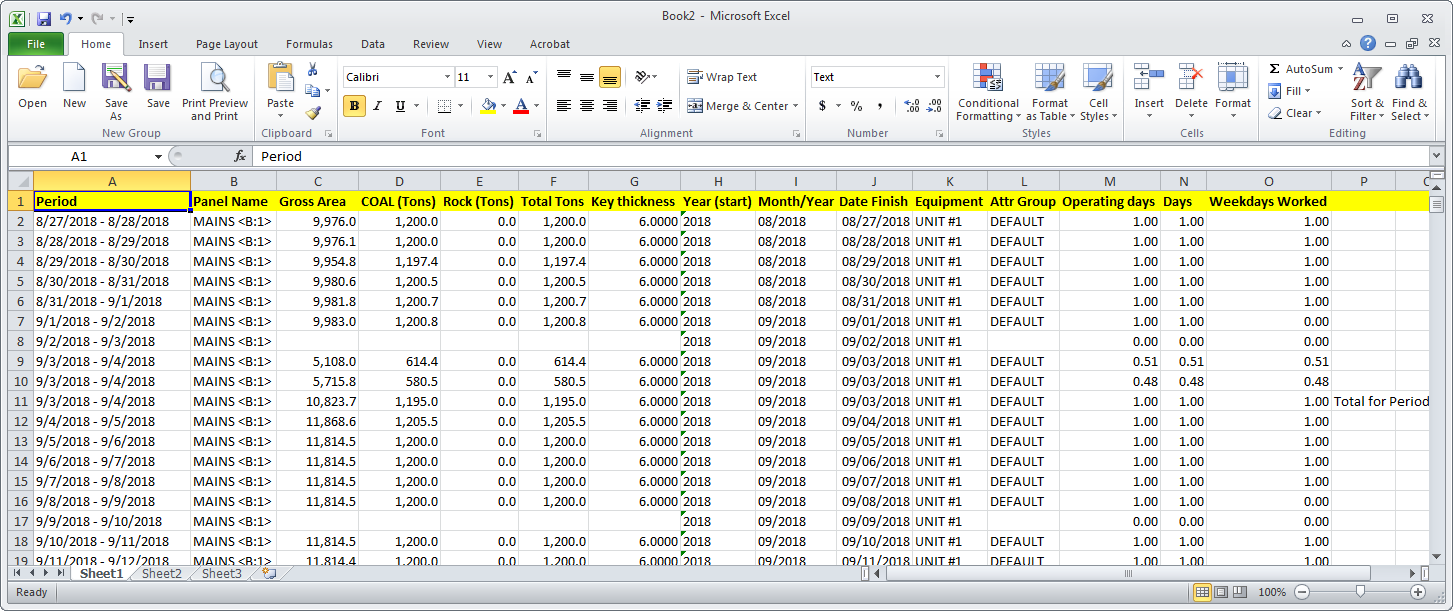

MS Excel

When the MS Excel tab is open reports can be exported directly to

new or existing spreadsheets, beginning on any specified sheet, row

and column. There are also options to include totals and text

header information in the file. When the options have been

specified click on the Export to Excel button. The

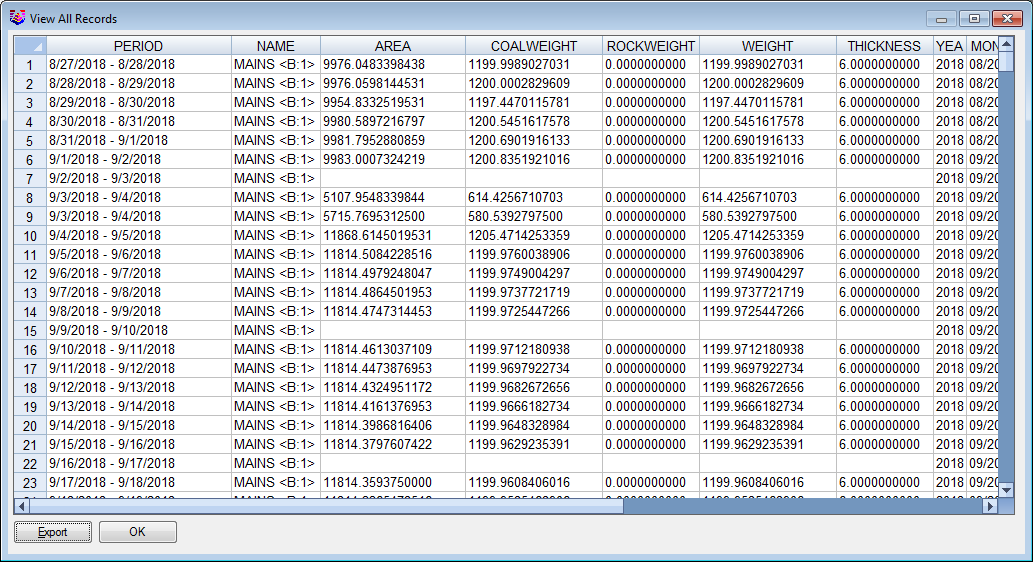

spreadsheet below was exported using this option.

Import/Export Options

At the Export button under Import/Export tab there are 6 options

under Export.

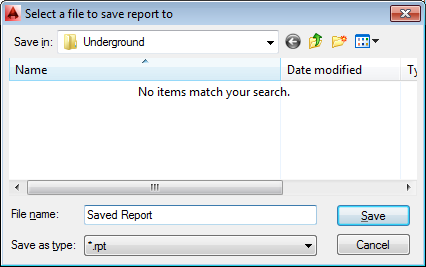

RPT format reports can be merged together, as shown above. The RPT

reports are the reports that can be loaded and viewed even after

the underground timing routine is closed, and accessed at a later

time.

Prompts

Select any part of mine plan: Pick any centerline in

the mine plan

Underground Timing Dialog

Pull-Down Menu Location: Underground

Keyboard Command: schedule_mine

The drawing above shows a simple mineplan layout of longwall

and continuous miner panels. The panel perimeters are drawn

on the PERIM layer, and the pillars are on the PILLARS layer.

The panels in this example were placed using Pick and

Place.

The Mining

Project dialog box above shows some of the key files used in the

mine timing. Options on the right side become active

depending on the items selected on the left side.