Road Rehabilitation

This lesson designs a road rehabilitation project for two lanes

of an Interstate highway. The top surface of the existing road has

already been milled and the top of the milled surface has been

surveyed. The two lanes are crowned in the center with a typical

cross slope of approximately 1%. The design is to add 8" of

concrete with a minimum cross slope of 1.56%.

Getting Started

To begin, let's open the project drawing and verify the proper

menu configuration is loaded.

- Open the drawing named rehab1_tutorial.dwg

installed in the Carlson Projects folder by default.

- Make sure the Civil menu configuration is loaded. From the

Settings menu, click Carlson Menus → Civil Menu.

Create Existing Surface

Our goal in this section is to create an existing ground surface

model named Exist-rd.tin. For input, there are survey

points for the existing base and polylines for the centerline and

edges of pavement.

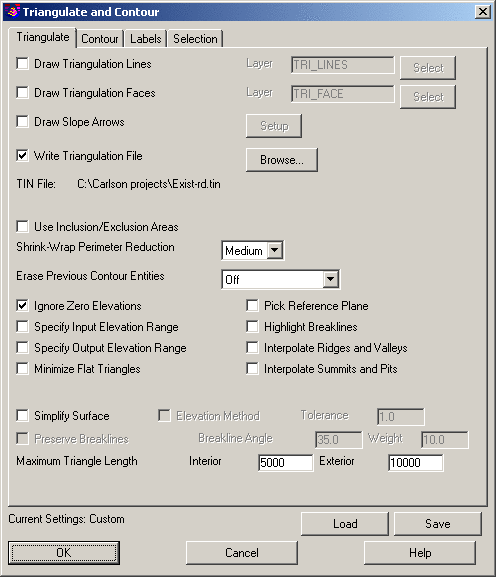

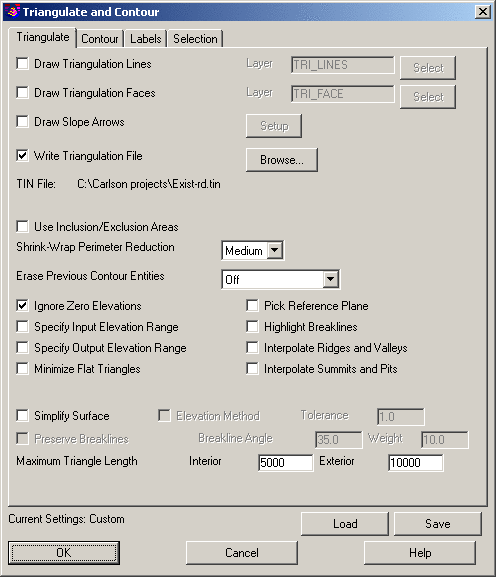

- From the Surface menu, click Triangulate & Contour and set

the values shown in the dialog box below. Of particular note are

the following settings:

- Write Triangulation File is enabled with the file name

specified.

- Use Inclusion/Exclusion Areas is disabled.

- Shrink-Wrap Perimeter Reduction is set to

Medium.

- Ignore Zero Elevations is enabled.

- Click the OK button on the dialog box and follow the prompts

below:

Select the points and breaklines to

Triangulate.

Select objects: Type ALL and press Enter.

Select objects: press Enter

Writing Triangulation File: C:\Carlson

Projects\Exist-rd.tin

This concludes the creation of an existing surface model of the

milled roadway surface.

Create Centerline

Our next task will be to create a horizontal centerline from

polyline data found in the drawing. Before we complete this task,

we'll want to freeze the BREAKLINE layer to expose the

polylines on the PROPOSED PAVEMENT layer.

- From the View menu, click Freeze Layer and follow the

prompts:

Pick entities on layers to be

frozen.

Select entities: Pick one of the pavement edge polylines and press Enter

when complete.

Freezing layer: BREAKLINE

- From the Centerline menu, click Polyline To Centerline File to

create a CL file from the center polyline in the drawing.

- Enter a file name of rehab.cl, pick the

polyline and enter a beginning station of 73258.51.

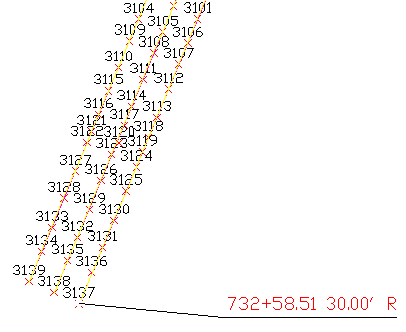

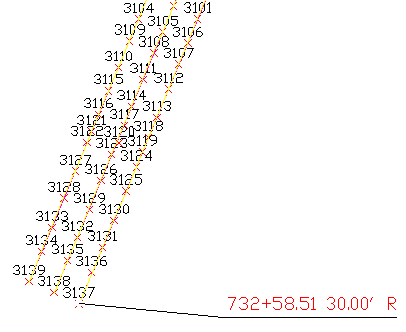

Create Existing Sections

Now that the horizontal path of the road has been established,

the next step will be to generate cross-section information of

existing conditions.

- From the Sections pull-down menu, choose Input-Edit Section

Alignment and supply a section alignment name of

rehab.mxs.

- At the centerline prompt, type C (for

"CL File") and select the rehab.cl file created

earlier.

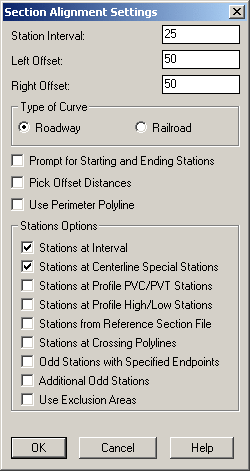

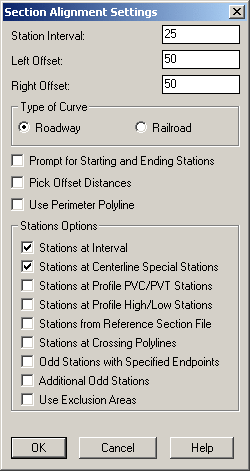

- For the Alignment Settings, set the Station Interval to 25 and

the Left/Right Offset values to 50.

- Click the OK button and then click the Save button on the next

dialog box showing the list of the section stations.

- Create the actual cross-section data through the Sections →

Create Sections From → Sections from Grid or Triangulation Surface

command and select:

- exist-rd.tin as the source of the surface model

- "Prompt" as the linking method between the surface

model and the output section file.

Note: With the prompt option, should the

definition of the surface model change, you will be prompted if

section data should update as well!

- rehab.mxs as the section alignment

- exist-rd.sct as the output section file

This completes the generation of the cross-sectional data of the

existing, milled road.

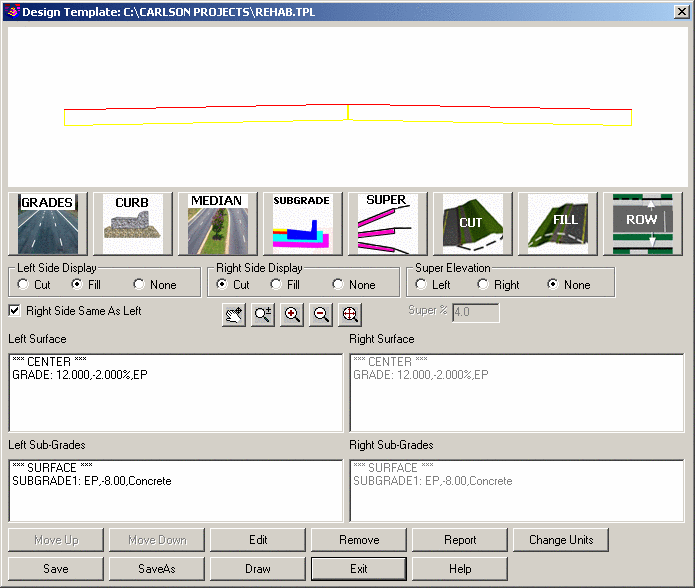

Design Template

Now that we've generated existing cross-section data, our next

task will be to create a design template "overlay" for the road

surface we wish to construct:

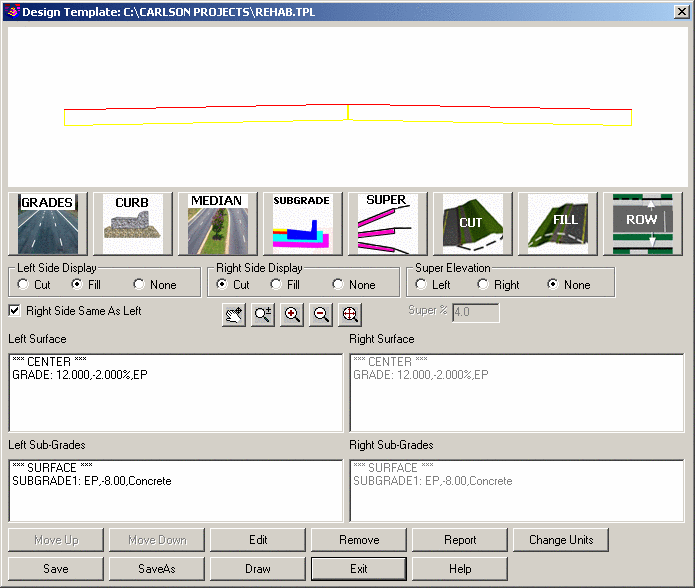

- From the Roads menu, click Design Template and create a new

template file named rehab.tpl.

- Click the Grades button and indicate the following

desired values for the pavement grade surface:

- -2% Linear Slope

- 12 feet for the Horizontal Distance

- EP for an ID of "edge of pavement"

Click OK to dismiss the Grade Dimensions dialog box.

- Click the Subgrade button and indicate the following

desired values for the subgrade surface:

- Straight Up for the Intersect Surface option. This

instructs the subgrade surface to intersect vertically to the grade

surface above.

- 0 for the horizontal offset distance. This instructs

the subgrade surface to start directly under the centerline of the

road.

- -8 inches for the Vertical Offset. This instructs the

subgrade to be 8 inches below the grade surface above and will

generate the minimum 8" pavement thickness specified earlier in

this lesson.

- EP for the Distance. This instructs the subgrade width

to be the same width as the EP (edge-of-pavement) width specified

in the Grade Dimensions.

Note: By using the parametric/variable ID points

(e.g. the "EP" code vs the 12' Horizontal

Distance, the subgrade width will vary as needed to accommodate the

pavement grade width!

- Concrete for the Material.

- Click OK when ready to dismiss the Grade Dimensions dialog box.

The proposed road template should resemble the following:

- That's all that needs to be defined in the template. Click the

Save button and then click Exit.

This completes the proposed definition of the new pavement

overlay.

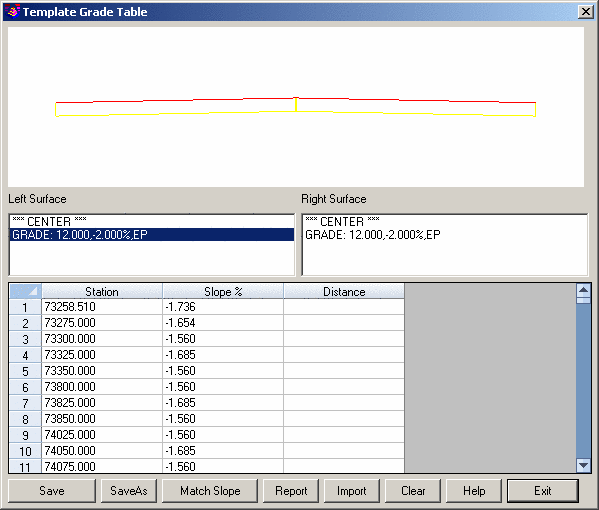

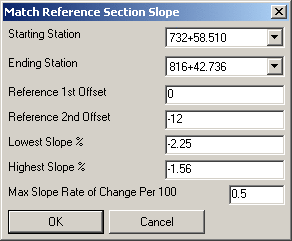

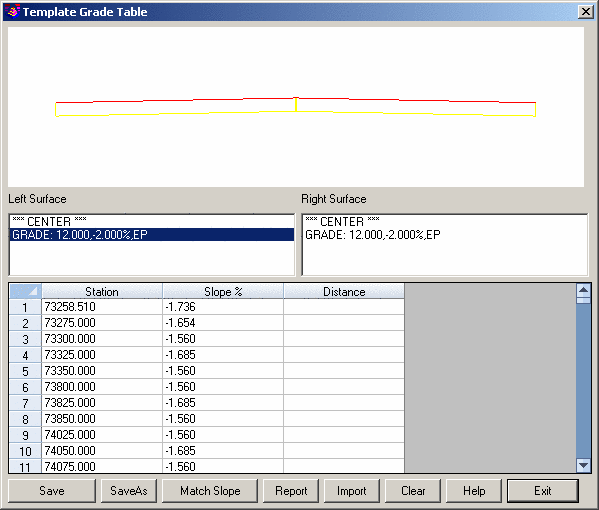

Template Grade Table

The next step is to design the proposed cross-slopes to follow

the existing section grades as much as possible.

- From the Roads menu, click Template Grade Table and create a

new Template Grade Table file named rehab.tgt and

specify the rehab.tpl created earlier as the template file

to process.

- Highlight the GRADE surface from the Left Surface list

and click the Match Slope button and identify the

exist-rd.sct file as the Section File to Process.

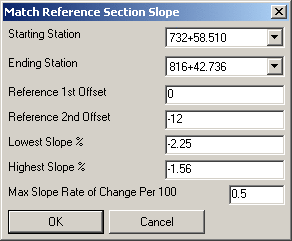

- For the Match Slope options, specify:

- 0 for Reference 1st Offset

- -12 for Reference 2nd Offset

Note: These values sample the existing sections at

the offsets specified to get the existing cross slope.

- -2.25 for the Lowest Slope %

- -1.56 for the Highest Slope %

Note: These values restrict the design

cross-slopes to be within the range specified.

- 0.5 for the Max Slope Rate of Change Per 100. This

restricts how much the design cross-slope can change between

stations. For example, with the maximum set to 0.5 and a

cross-slope of -2.0% at station 1+00, the cross-slope at station

2+00 must be between -2.5% and -1.5%.

- After picking OK on this dialog, highlight the right side grade

and pick the Match Slope button.

- Use the same parameters as the left side except use Reference

Offsets of 0 and 12 and then pick OK.

- From the Template Grade Table dialog box, click Save and then

click Exit.

This completes the process of generating a Template Grade

Table.

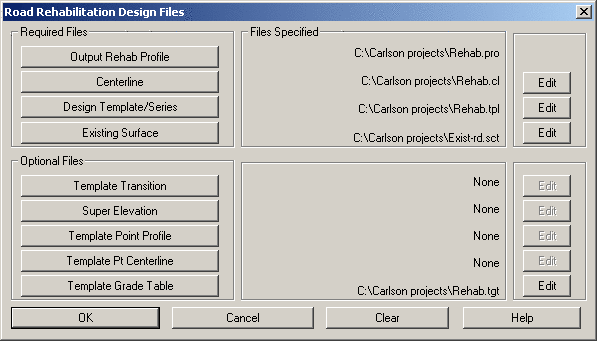

Design Profile

The next step is to define the design profile that minimizes

quantities while satisfying the design parameters.

- From the Roads menu, click the Road Rehabilitation Profile

command and specify a new file name

rehab.pro.

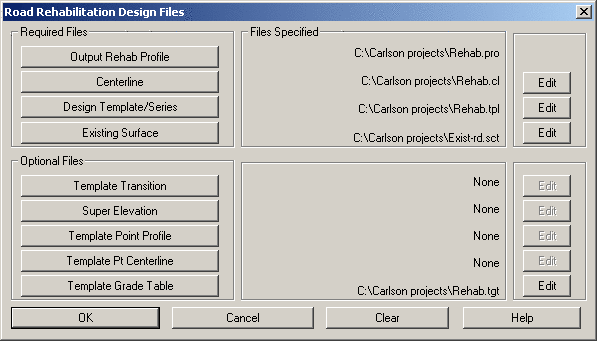

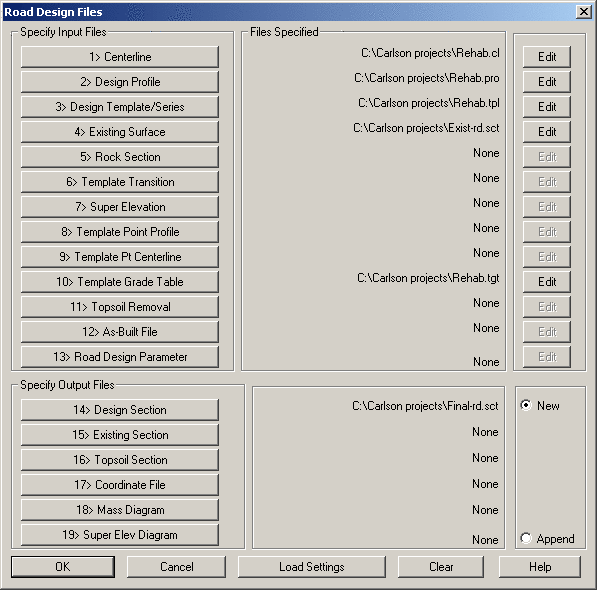

- For the Centerline, Design Template, Existing Surface and

Template Grade Table, choose the files created in the previous

steps as shown below:

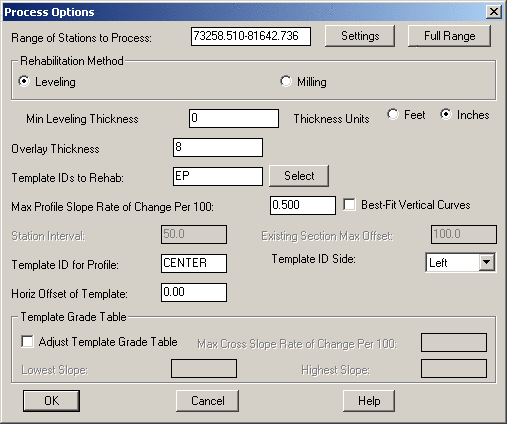

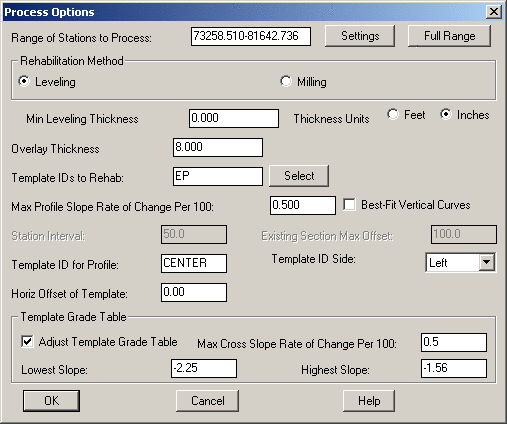

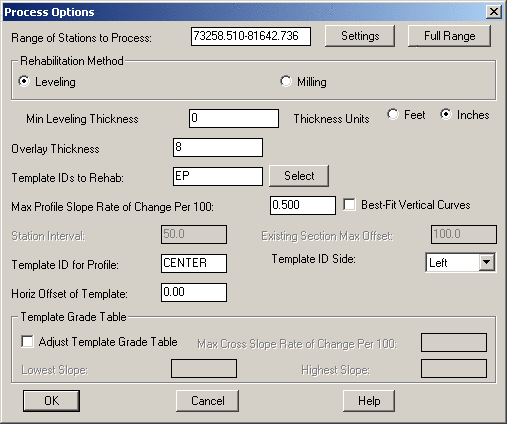

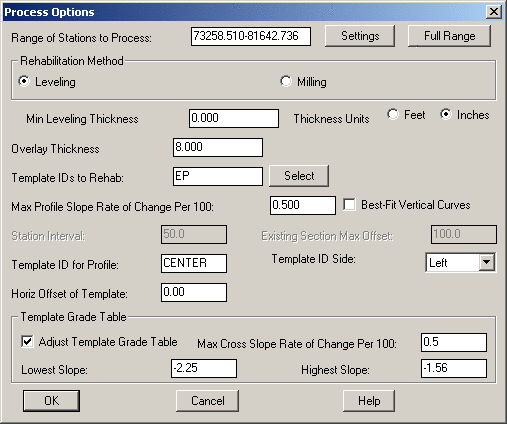

- Click the OK on the file selection dialog to get to the Process

Options dialog and specify the following values:

- Leveling for the Rehabilitation Method

- 0 inches for the Minimum Leveling Thickness

- 8 inches for the Overlay Thickness (the same as the

Subgrade thickness defined in the Design Template).

- EP for the Template IDs to Rehab (the same as the

pavement edge ID defined in the Design Template).

- 0.5 for Max Profile Slope Rate of Change Per 100 to

restrict the rate of profile grade change.

Note: This setting is similar to the Max Slope

Rate of Change Per 100 in Match Slope for Template Grade Table

except this one applies to the profile slope instead of the

cross-slope.

- Leave the rest of the settings as the defaults as shown.

- Click the OK button to process and generate the desired

rehab.pro file.

This completes the process of generating a design profile.

Adjustments to the profile can be made through the Profiles →

Design Road Profile → Input-Edit Road Profile command.

Process Road Design

The road design is now ready to be computed.

- From the Roads menu, initiate the Process Road Design

command.

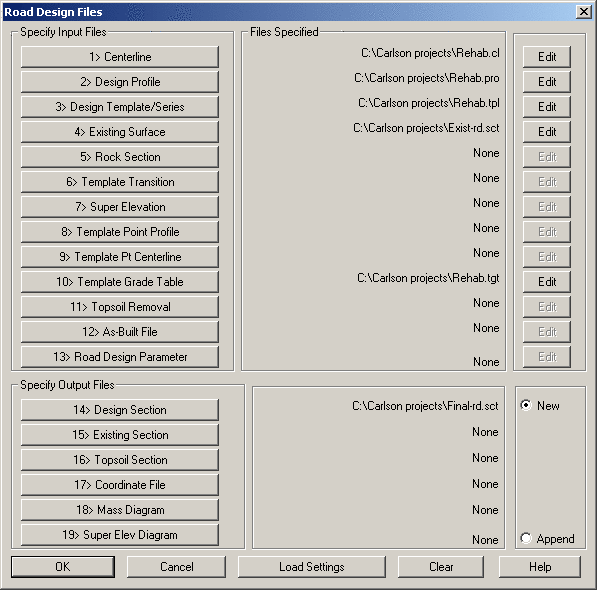

- Make sure the Centerline, Profile, Design Template, Existing

Surface and Template Grade Table options are each utilizing the

files created earlier.

- Click on the Design Section button to create a

new file named Final-rd.sct as illustrated below:

- Click OK when ready to continue.

- On the Additional Road Design Parameters dialog box, accept the

default values and click OK to initiate the processing of the

design.

The program reports the quantities per station and totals in a

report similar to that shown below:

Process Road Design

Template File> C:\Carlson Projects\rehab.tpl

Profile File> C:\Carlson Projects\rehab.pro

Existing Surface File> C:\Carlson Projects\exist-rd.sct

Centerline File> C:\Carlson Projects\rehab.cl

Template Grade Table File> C:\Carlson Projects\rehab.tgt

Design Section Output File> C:\Carlson Projects\Final-rd.sct

Processing 732+58.510 to 816+42.736

Total Cut : 0.001 C.F., 0.000 C.Y.

Total Fill: 12449.816 C.F., 461.104 C.Y.

Cut to Fill Ratio: 0.00

Total Left Subgrade1 - Concrete: 33533.838 C.F., 1241.994 C.Y., 100603.375 S.F., 11178.153 S.Y.

Total Right Subgrade1 - Concrete: 33533.140 C.F., 1241.968 C.Y., 100601.280 S.F., 11177.920 S.Y.

Note: Be aware of the following important

values:

- The Total Fill is the amount of extra leveling.

- The Subgrade Volumes are the amount of overlay.

This completes an initial process of the design data.

Draw Sections

Our next task will be to visually verify the design by

generating cross-section plots.

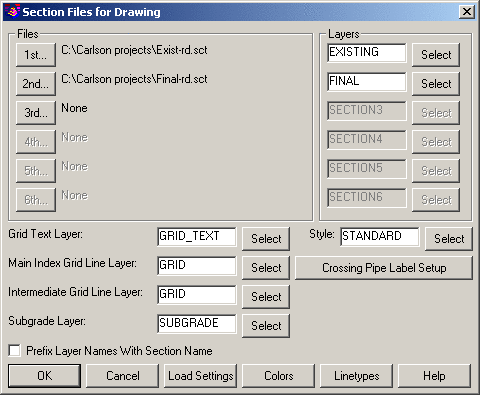

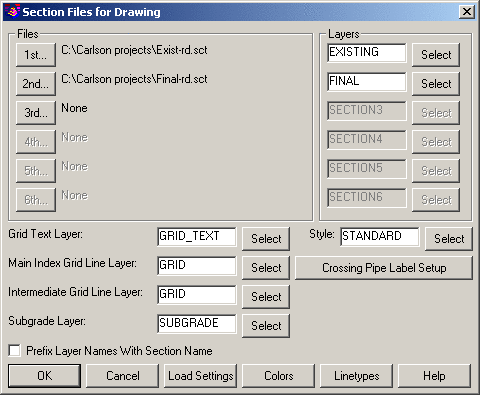

- From the Sections menu, click Draw Section File. Set the 1st

section file to Exist-rd.sct and the 2nd section file to

be Final-rd.sct as illustrated below:

- On the Draw Section File dialog box, set the following

values:

- 10 for the Horizontal Scale value.

- 5 for the Vertical Scale value.

- Click the Scan Files to Set Defaults button to "read"

the section files specified earlier and retrieve data from

them.

- Vertical Stack for the Type of Plot.

- Enable the Label Slopes option and then click the

Set button to ensure:

- Label Section 1 is enabled.

- Label Section 2 is enabled.

- Click the OK button and then screen pick a point in a blank

area of the drawing.

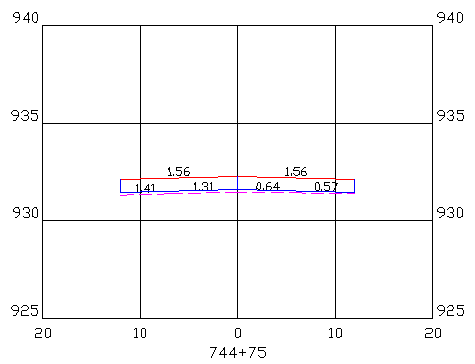

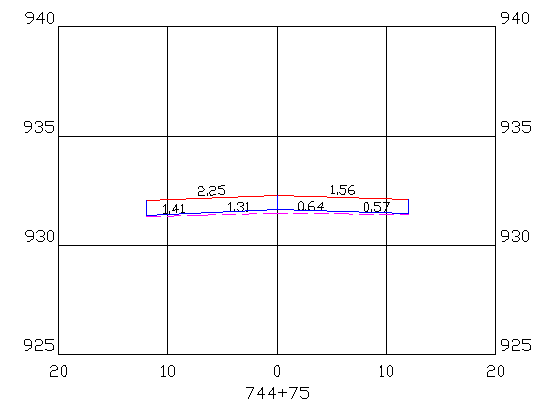

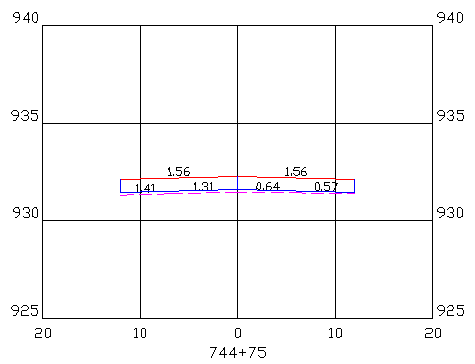

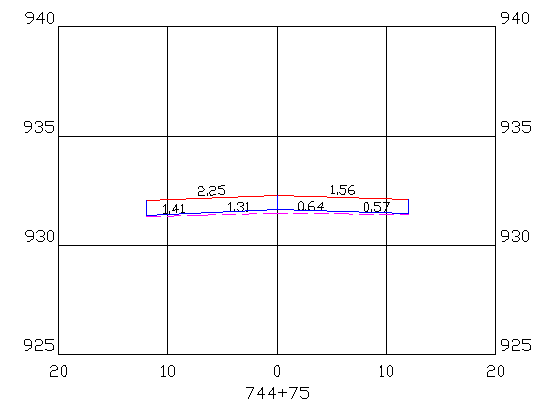

This station shows the existing surface with slopes ranging from

1.41% left to 0.57% right and the design with slopes 1.56% left and

right. Since 1.56% was the minimum design cross slope, the design

is steeper than existing and there is some leveling needed between

the design overlay and the existing.

The profile elevation for this station was set by the right edge

since this was the highest point. There is some extra leveling fill

needed on the left side. This left side slope can be steeper

because our design cross-slope range is 1.56% to 2.25%.

Let's continue with additional steps to refine the design!

Design Profile (with Template Grade Adjustment)

From the Roads menu, re-run the Road Rehabilitation Profile

command again.

- Use all the same files for the first dialog.

- On the second dialog, enable the Adjust Template Grade Table

toggle and set the Lowest and Highest Slopes and the Max Cross

Slope Rate to the same design parameters used during Template Grade

Table as shown below:

- Click the OK button when ready.

Note: The Adjust Template Grade Table

option checks the left and right grades while creating the

rehabilitation profile and adjusts the slope on the side that is

not controlling the profile grade.

Process Road Design (with Template Grade Adjustment)

From the Roads menu, issue the Process Road Design command again

with all the same settings from the previous run.

Process Road Design

Template File> C:\Carlson Projects\rehab.tpl

Profile File> C:\Carlson Projects\rehab.pro

Existing Surface File> C:\Carlson Projects\exist-rd.sct

Centerline File> C:\Carlson Projects\rehab.cl

Template Grade Table File> C:\Carlson Projects\rehab.tgt

Design Section Output File> C:\Carlson Projects\Final-rd.sct

Processing 732+58.510 to 816+42.736

Total Cut : 21.607 C.F., 0.800 C.Y.

Total Fill: 11152.921 C.F., 413.071 C.Y.

Cut to Fill Ratio: 0.00

Total Left Subgrade1 - Concrete: 33533.761 C.F., 1241.991 C.Y., 100603.375 S.F., 11178.153 S.Y.

Total Right Subgrade1 - Concrete: 33533.107 C.F., 1241.967 C.Y., 100601.280 S.F., 11177.920 S.Y.

For this run, the Template Grade Table has been adjusted. In the

report, the overlay quantities are the same and the fill quantity

for the extra leveling has been reduced as expected. In this case,

the Template Grade Adjustment reduced the Total Fill (extra

leveling) amount from 461.104 C.Y. to 413.071 C.Y. (about a 10%

reduction in needed leveling material).

Draw Sections

From the Sections menu, click Draw Section File command to

redraw the sections data again using all the same settings. The

only difference in the final section is that the left side is

steeper to better match the existing surface.

This concludes this tutorial lesson on roadway

rehabilitation.