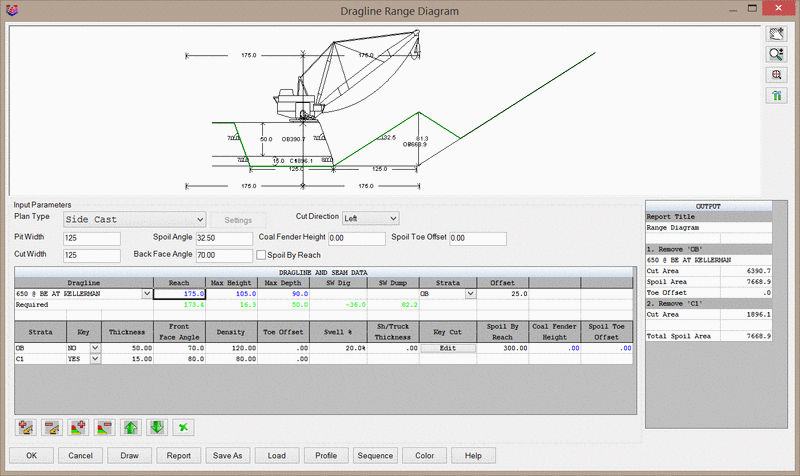

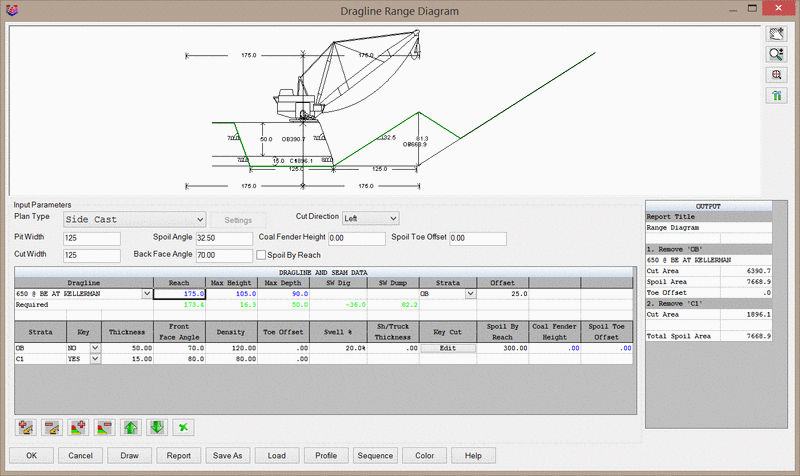

Range Diagram

The Range Diagram command is an interactive tool for analyzing

dragline cut scenarios. This is a quick and easy way to find

parameters such as pit width, or to size a dragline to fit the

geology. Methods of mining include Side Cast, Extended Bench, Dozer

Bench, and Spoil Bench. Output includes both drawing the sections

in CAD and printing out reports as PDF files, where each step is a

separate page. The main dialog is shown below.

Graphics Window

The visual display of the range diagram is shown at the top of

the dialog in the graphics window. Four icons are located to the

right of the window, which control display settings and camera

movement. These icons, listed from top to bottom are:

Pan: This icon will allow you to pan around the graphics

window by clicking-and-dragging the left mouse button.

Zoom: This icon will allow you to zoom in and out in the

graphics window by clicking-and-dragging the left mouse button.

Zoom Extents: This icon will zoom to the extents of the

diagram.

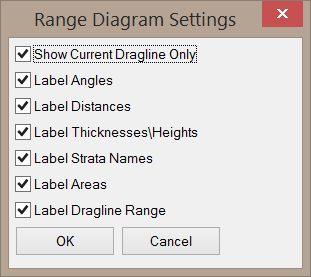

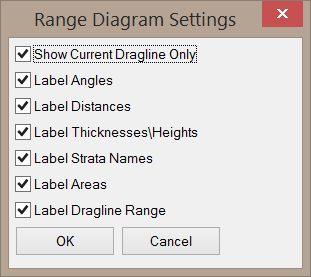

Set Colors and Settings: This icon will open the below

dialog, which controls the labels shown in the graphics window. To

change the colors of the various entities, use the Color Panel

which controls the color of various labels. The Select

button next to each entity will open the CAD color palette.

Show Current Dragline Only: This option

will only show the current dragline, rather than showing all

dragline passes at once.

Label ___: The remaining options on this dialog will label

the respective items in the graphics window.

PDF X/Y: These settings control the position where the image

will appear in the PDF withe the Report option is

used.

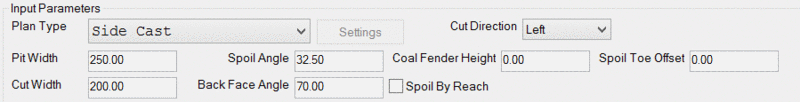

Input Parameters

This section of the help document discusses the Input

Parameters, shown below.

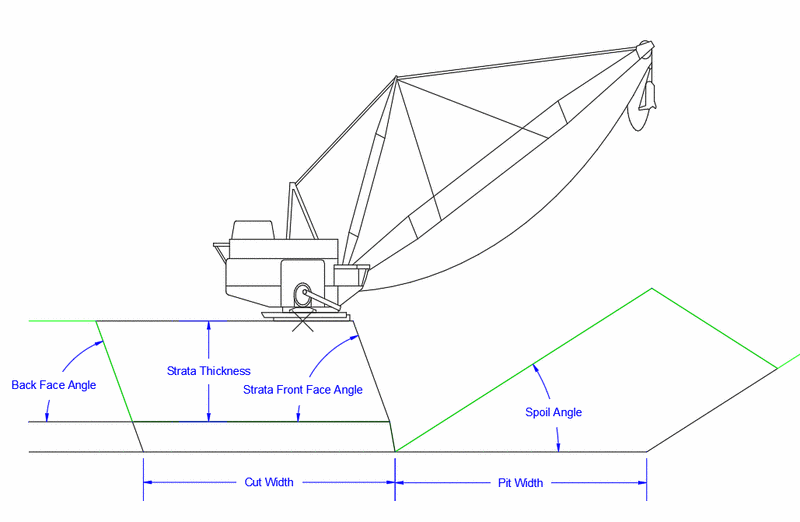

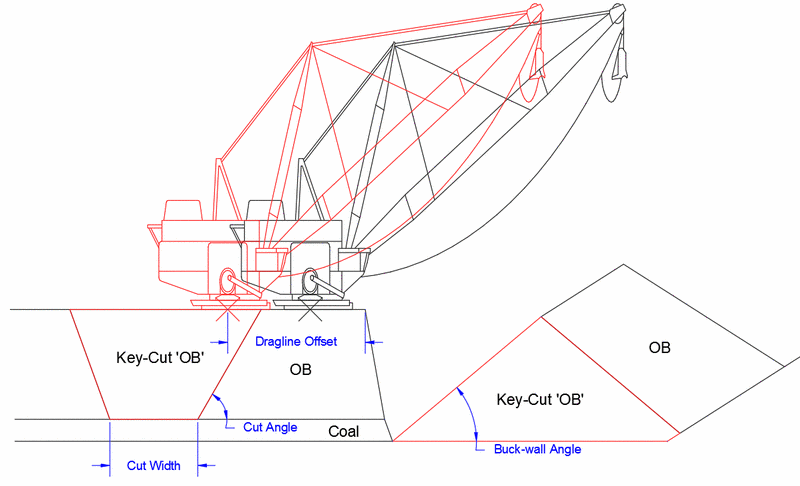

Many of these options are visually explained below.

Plan Type: This option

sets the mining method. Four options are available:

The

Side Cast method places the dragline on the waste material

with a previously cut pit on one side. The dragline strips the

waste material and places it into the open pit.

The Extended Bench method is similar to the Side Cast

method, but the dragline will first place waste material at the

edge of the existing highwall, thus extending the current bench

further into the open pit. This allows the dragline to position

itself on the extended bench, where it can then resume side casting

material further into the open pit. This allows the dragline to

spoil the material further into the open pit, but requires rehandle

of the material used to create the extended bench.

The Dozer Bench method is similar to the Side Cast method,

but is preceded by a dozer pushing a portion of the existing bench

into the open pit. This allows draglines with a shallower digging

reach to effectively dig out greater depths of

overburden.

The Spoil Bench method is similar to the Side Cast method,

but the dragline is positioned on the spoiled material rather than

on the active bench.

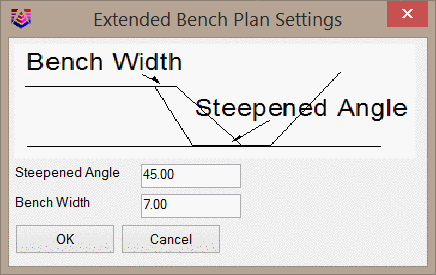

Settings: This button controls settings specific to the

Extended Bench, Dozer Bench, and Spoil Bench Plan Types, depending

on which Plan Type is currently selected. Each setting is visually

represented in the settings dialog.

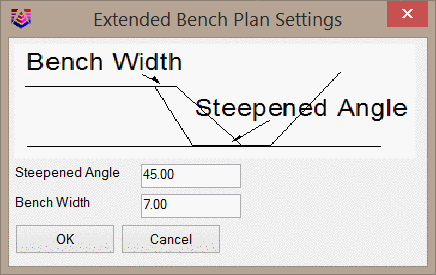

The Extended Bench Settings are shown below.

Steepened Angle: This value controls the angle,

in degrees, of the new slope of the extended bench.

Bench Width: This value controls the width of the extended

bench.

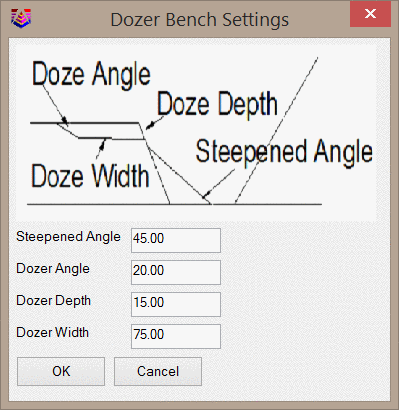

Steepened Angle: This value controls the angle,

in degrees, of the spoil pushed by the dozer into the pit.

Dozer Angle: This value controls the push angle of the dozer

until it reaches the Dozer Depth.

Dozer Depth: This value controls the digging depth of the

dozer.

Dozer Width: This value controls the width from the existing

highwall to the start of the flat portion of the dozer bench. Note

that the full dozer bench may be longer than this value depending

on pit geometry.

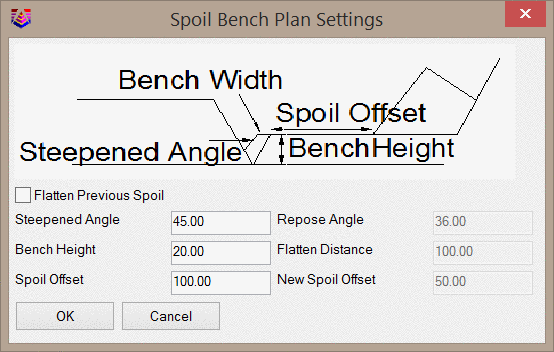

The Spoil Bench Settings are shown below.

Flatten Previous Spoil: This option is only

applied when two dragline passes are designed. When selected, the

left three settings of this dialog will be made unavailable and the

right three setting will become available. When a previous spoil

pile is flattened for the dragline bench, it is always pushed

further into the pit, away from the unmined ore.

Steepened Angle: This value controls the spoil angle from

the pit floor up to the dragline spoil bench.

Bench Height: This value controls the height of the dragline

spoil bench.

Spoil Offset: This value controls the width of the dragline

spoil bench.

Repose Angle: When flattening a previous spoil pile for the

new dragline bench, this value controls the repose angle, in

degrees, of the pushed material.

Flatten Distance: When flattening a previous spoil pile for

the new dragline bench, this value controls the width of the spoil

that is flattened in preparation for the dragline.

New Spoil Offset: When flattening a previous spoil pile for

the new dragline bench, this value controls the spoil offset from

the previous spoil pile.

Cut Direction: This options

determines whether the cut is advancing to the right or the left in

the graphics window.

Pit Width: This value

sets the width of the existing, open pit. This can represent a

previous pass, or a boxcut.

Spoil Angle: This value

sets the angle of repose, in degrees, for the spoiled

material.

Coal Fender Height: This value sets the height of the

remaining coal that may be covered with spoil. This wedge of coal

that is covered by the spoil is known as a fender.

Spoil Toe Offset: This value places the toe of the spoil

the specified distance from the bottom of the coal seam.

Cut Width: This value

sets the width of the new cut. This is the field that is frequently

changed in order to find an adequate pit size.

Back Face Angle: This

value sets the highwall angle, in degrees, for the new cut

for all strata.

Spoil by Reach: This option places the top of the pile at

a distance specified in the Spoil by Reach column of the

Dragline and Seam Data section of the dialog. When selected, the

Coal Fender Height and Spoil Toe Offset fields will be

unavailable.

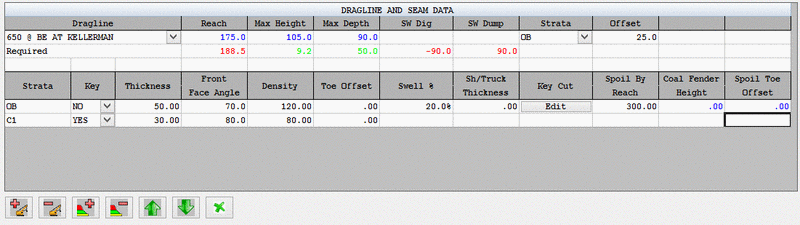

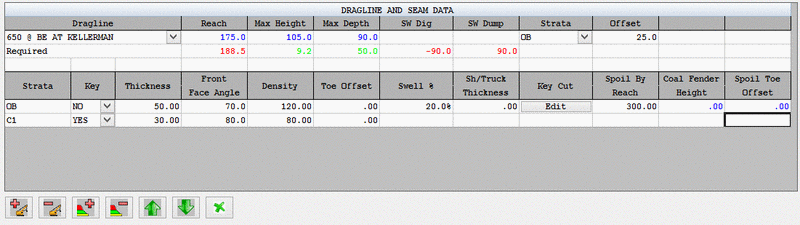

Dragline and Seam Data

This section of the help document discusses the Dragline and

Seam Data inputs, shown below.

Note that this section of the dialog uses colored

text to highlight design flaws. Black text is used for simple input

values, blue text is used for maximum available values, green text

is used for values that are attainable with the current design, and

red text is used for values that are not attainable with the

current design.

Dragline: This

dropdown menu sets the dragline to use for the current pass. When

selected, a list of predefined draglines will be shown. Draglines

may be added/edited via the Define Dragline Equipment command

(Surface Mining Module > Surface Pulldown Menu).

Reach: This value

displays the horizontal reach of the selected

dragline.

Max Height: This value

displays the vertical dumping height of the selected dragline, as

measured from the bottom of the dragline.

Max Depth: This value

displays the vertical digging depth of the selected dragline, as

measured from the bottom of the dragline.

SW Dig: This value

displays the required dragline Swing Angle, in degrees, on the

digging side. If this value is shown in red, then the dragline

cannot reach the entire cut, even with a -90 degree swing

angle.

SW Dump: This value

displays the required dragline Swing Angle, in degrees, on the dump

side. If this value is shown in red, then the dragline cannot reach

far enough into the pit to adequately dump the waste material, even

with a 90 degree swing angle.

Strata (Top Section): This option

sets the strata on which the dragline is

positioned.

Offset: This value sets the distance

between the highwall and the center of the dragline

tub.

Strata (Bottom Section): This column lists all strata to be handled

in the current dragline pass.

Key: This column marks each strata as key or non-key (waste)

material. Only non-key material will be spoiled.

Thickness: This column controls the thickness of each

strata.

Front Face Angle: This column controls the highwall angle,

in degrees, of each strata. Note that a value of 90 represents a

vertical highwall.

Density: This column sets the density for each strata.

English units are set to lbs/ft3 and metric units are

set to kg/m3.

Toe Offset: This column controls the bench width between

strata.

Swell %: This column lists the swell percent of the spoiled

material. A material with a swell of 10% will occupy 1.1 times it's

original volume after it has been spoiled.

Sh/Truck Thickness: This column controls the thickness of

each non-key strata that is to be excavated by truck and shovel

(material that won't be spoiled into the open pit).

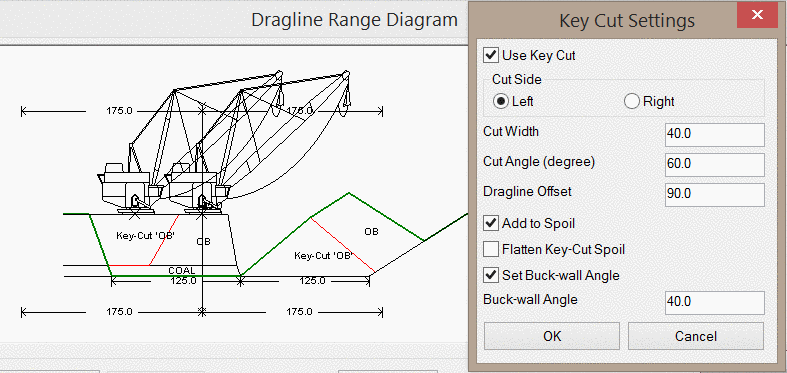

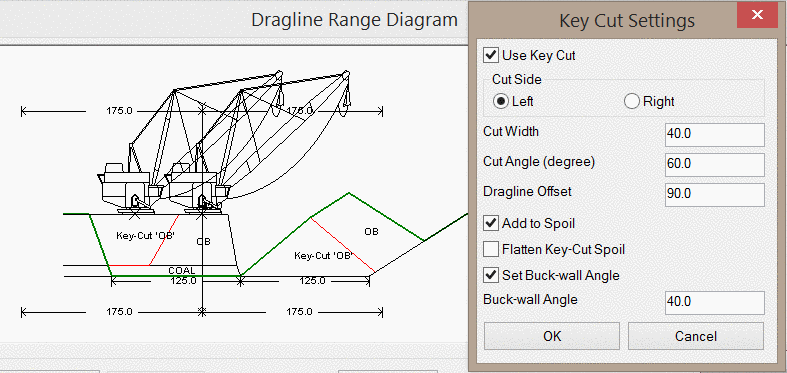

Key Cut: This column controls if each non-key material is to

be excavated with a key cut. Clicking the Edit button will

open the below dialog, which is shown next to an example of the

results it will produce.

Use Key Cut: This option toggles the use of the

key cut.

Cut Side: This option controls the location of the key cut -

either the right or the left side of the cut area.

Cut Width: This value controls the width of the key cut.

Cut Angle (degree): This value controls the cut angle

of the key cut.

Dragline Offset: This value controls the distance between

the crest of the highwall and the center of the dragline, during

the key cut.

Add to Spoil: This option will actually spoil the material

excavated in the key cut. If not selected, the material from the

key cut is assumed to be haul away to another dump

location.

Flatten Key-Cut Spoil: This option is only available when

the Add to Spoil option is selected. This option will flatten the

top of the spoil pile created from the key cut. When selected, the

Spoil Bench Settings dialog will be used to set the parameters for

the flattened bench.

Set Buck-wall Angle: This option will set the angle of repose

for material spoiled from the key cut. This allows for two angles

of repose to be displayed in the overall spoil pile. Several of the

above parameters are represented below.

Coal Fender Height: This column displays the required coal

fender height for the given Spoil by Reach value. This value is

calculated automatically.

Spoil Toe Offset: This column displays the required spoil

toe offset for the given Spoil by Reach value. This value is

calculated automatically as the distance from the toe of the spoil

to the to of the strata.

Spoil by Reach: Yes or No. This column sets the spoil

distance for each strata when the Spoil by Reach toggle above is

selected.

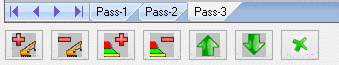

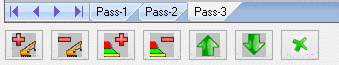

Bottom-row Icons: At the bottom of the Dragline and Seam

Data section of the dialog are six icons, shown below.

Listed in order from left to right:

Add Pass: This icon will add an additional dragline pass to the

cut. This can be a different dragline or an additional pass of the

same dragline. Each dragline pass is listed on a separate tab. Note

that any strata layers listed for one dragline pass will be

completely excavated in that pass. If a strata is to be excavated

with dragline pass #2, that strata should not be listed in dragline

pass #1. An example of the tabs shown for three dragline passes are

shown above.

Remove Pass: This icon will remove the currently selected

dragline pass.

Add Strata: This icon will add a new strata to the current

dragline pass.

Remove Strata: This icon will remove the currently selected

strata.

Move Up: This icon will move the currently selected strata

up in the list.

Move Down: This icon will move the currently selected strata

down in the list.

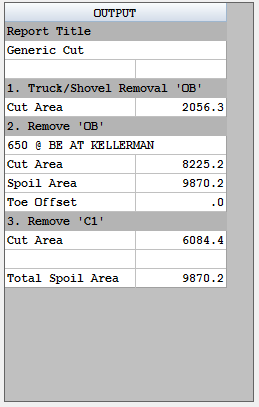

Output

The output window will output the results of each step of the

dragline sequence. Steps will be added and removed

automatically.

Additional Commands

This section of the help document discusses the additional

commands on the dialog, shown below.

Draw: This buttton will draw the dragline sequence in CAD.

No dimensions will be labeled; only strata. Each step of the

sequence will be drawn separately, with the first step shown at the

bottom.

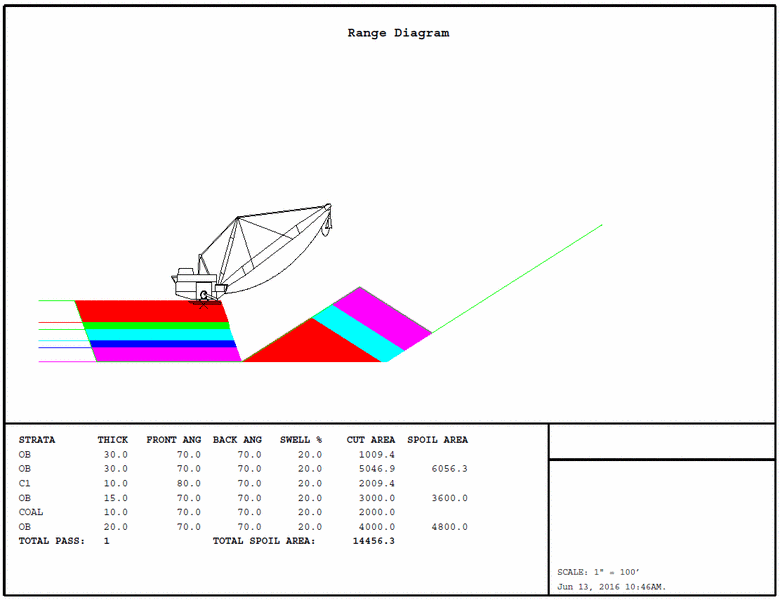

Report: This button will create a multi-page PDF document

where each step in the section will be on a separate page. The last

page of the report will show all steps, as shown below.

Profile: This button will save a profile (.pro file type) of

the final step of the dragline sequence.

Sequence: This button will save the dragline sequence (.seq

file type). This file can be used to extrude the dragline steps

across a centerline via the Process Dragline Sequence command

(Surface Mining Module > Surface Pulldown Menu).

Pulldown Menu Location: Surface

Keyboard Command: ranged

Prerequisite: dragline equipment defined