Spoil Placement Timing

This command brings all the spoil commands together as a final step

and performs the timing and scheduling of the spoil placement. The

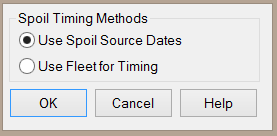

first screen will allow you to choose two options for timing;

either ‘Use Spoil Source Dates’ or ‘Use Fleet for Timing’ (shown

below). These two options will produce very different results, and

should be selected depending on the needs of spoil removal and

placement.

The ‘Spoil Source Dates’ option will move the material to the spoil

area as it is excavated from the pit based on the production

schedule. This option requires a spoil file (.spo) generated from

Surface Equipment Timing. A .spo file generated from Surface Mine

Reserves does not include start and end dates for the pit

excavation, and therefore there are no Spoil Source Dates to be

used.

The ‘Use Fleet for Timing’ option can be used with a .spo file

generated from either Surface Mine Reserves or Surface Equipment

Timing. This option does not consider the production schedule of

the mine, and will instead move the spoil material as quickly as

the haulage fleet will allow. As this option does not

consider the production schedule, in general it will be sensible to

only use a .spo file generated with Surface Mine Reserves with this

option.

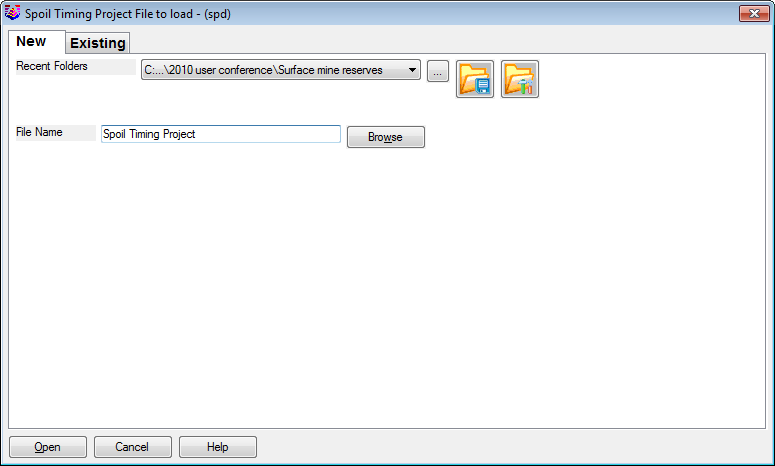

After selecting the timing option, you will be prompted for a Spoil

Timing Project file (.spd). This file stores information concerning

the spoil sources, spoil volumes, start and end dates of

excavation, spoil/pit centroid locations, haul fleet production

capacities, spoil attributes, etc.

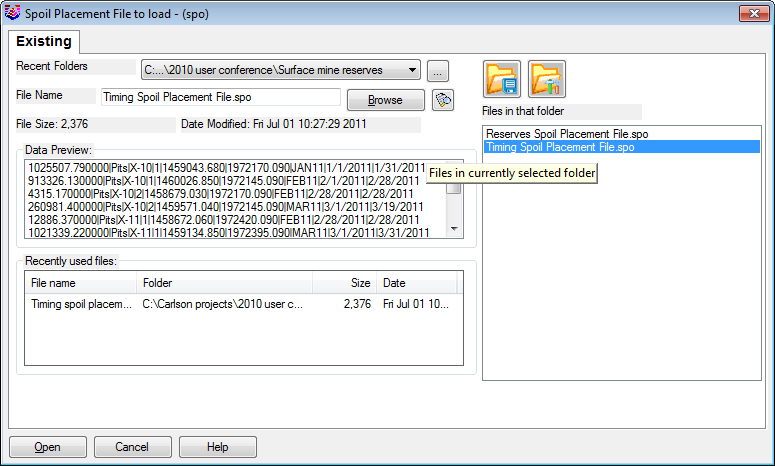

After specifying the .spd file, you will be prompted to select the

.spo file.

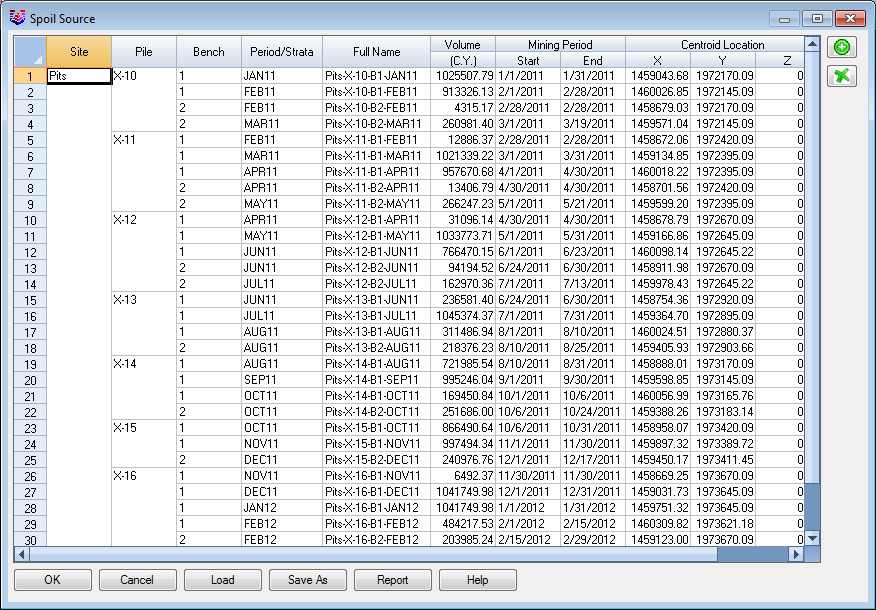

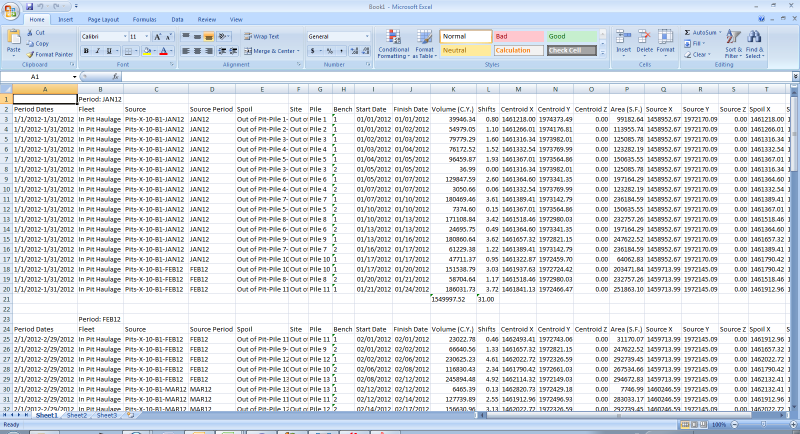

Once the .spo file has been selected, you will see a preview of the

file which can be edited before it is used for the spoil timing.

The preview of the spoil source is shown below.

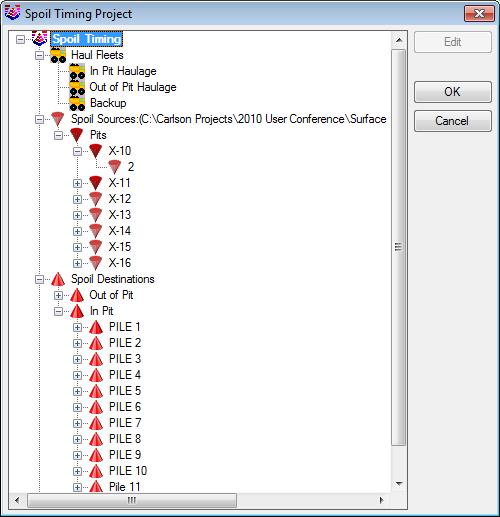

The next dialog shown will be the Spoil Timing Project Manager.

This shows a tree structure of the project, which includes the haul

fleet (if used), the spoil sources, the spoil destinations, and the

spoil attributes. Certain aspects of this dialog can be edited

using the ‘Edit’ button when a field is highlighted. This dialog is

shown below.

After clicking ‘OK’, you will see one of two dialogs, depending on

which timing option you selected. The two options are detailed in

the following two sections.

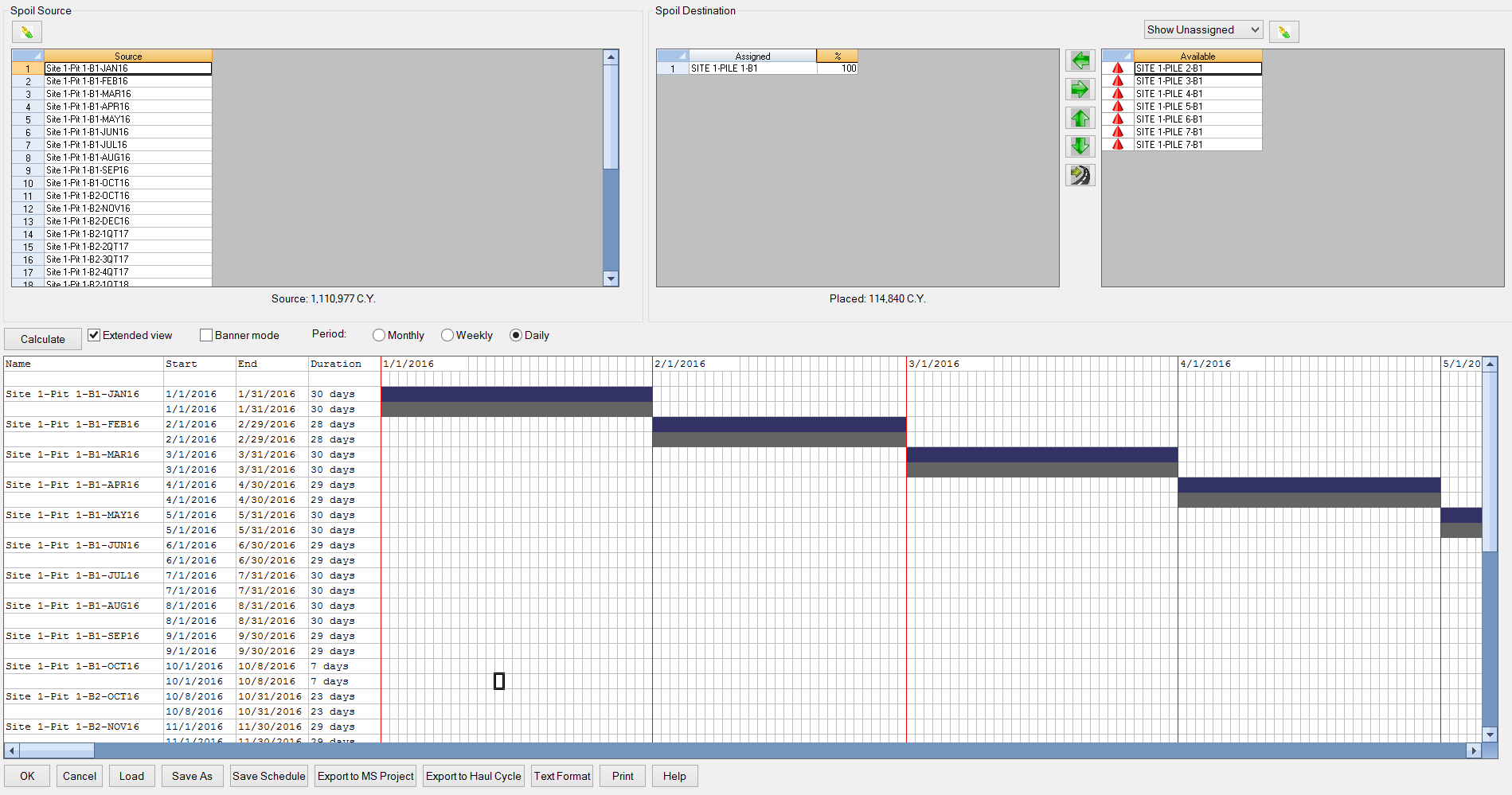

Use Spoil Source Dates for Timing

Note that this option will not require a haulage fleet to calculate

spoil timing. The Spoil Timing Project Manager will therefore not

include haul fleet information. This dialog is shown below:

This dialog consists of list of spoil sources by time period, a

list of assigned and available spoil destinations, and a Gantt

chart which shows the timing of the spoil placement.

The spoil source list shows the time period in which the spoil

material will be available for placement. Note that there are no

options to select or deselect the spoil sources to be used for

spoil timing, as this information is read directly from the .spo

file; all spoil from the mine pits must be used for timing

calculation.

The assigned and available lists shows the spoil destinations that

can be used for timing. Spoil destinations can be moved between the

available and assigned lists by using the left/right arrows between

the two lists. The up/down arrows between the lists controls the

order in which the spoil areas will be filled. The arrow-and-road

icon will automatically assign spoil destinations based on the

shortest haul distance between the spoil source and the spoil

destination. This command requires you to have selected the haul

roads using the Haul Road Manager command.

The assigned list also shows the fill percentage of each spoil

pile. Note that each spoil pile will be filled to capacity before

spoil is placed in the next pile. Both the spoil source and spoil

destination information can be directly edited by clicking the

green pen icons above each list. The total amount of spoil to be

moved is listed under the spoil source list. The total amount of

spoil that has been assigned to a spoil destination is listed under

the assigned list.

The bottom section of the dialog shows a Gantt chart of the spoil

placement timing. The use of Gantt charts are discussed in the

Surface Equipment Timing section of the help manual. Clicking

‘Calculate’ will determine the final timing of the spoil placement.

As the dialogs shown after clicking ‘Calculate’ are the same for

both the ‘Use Spoil Source Dates for Timing’ and the ‘Use Fleet for

Timing’ options, discussion of the output is discussed in the Spoil

Calculation Output section of this page. One item that is specific

to Gantt charts in the Spoil Timing dialog is the Export to Haul

Cycle option. This option exports a .sph file which can be used

with the Haul Cycle Analysis command to calculate a more detailed

report of the timing associated with spoil placement.

You may also save and load the spoil timing assignments in a Spoil

Assigment file (.stm)

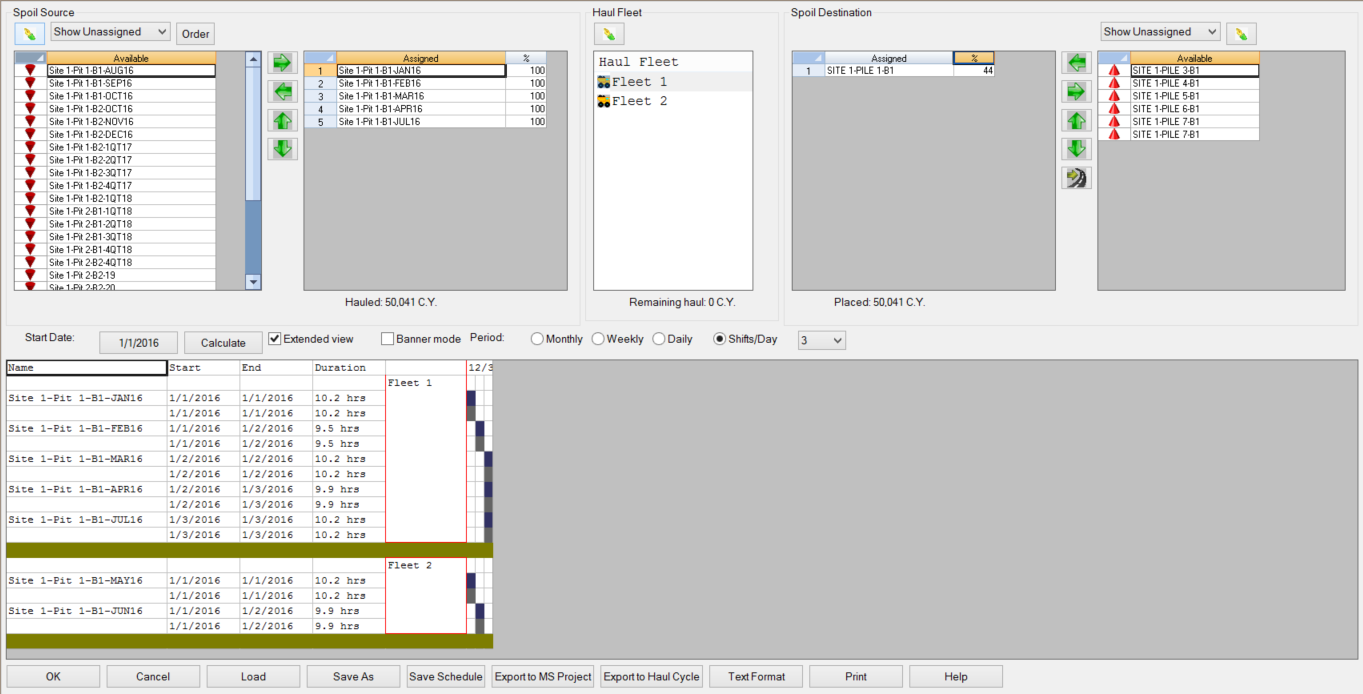

Use Fleet for Timing Option

Note that this option will require a haulage fleet for timing. With

this option, you may create multiple haulage fleets, which can be

assigned to various spoil sources and destinations for timing.

The Spoil Placement Timing dialog for this option will appear as

shown below.

Unlike the dialog shown for the ‘Use Spoil Source Dates for Timing’

option, this dialog allows you to use only specified spoil sources

for timing. Aside from this difference, the two dialogs are similar

in functionality. Spoil sources and destinations can be moved

between the assigned and available lists and reordered using the

green arrows between the lists. This dialog also shows a new list

of the haul fleets that can be used. Selecting a haul fleet will

list the spoil sources and destinations that are assigned to that

fleet. Another additional feature to this dialog is that you can

specify a start date for the spoil timing.

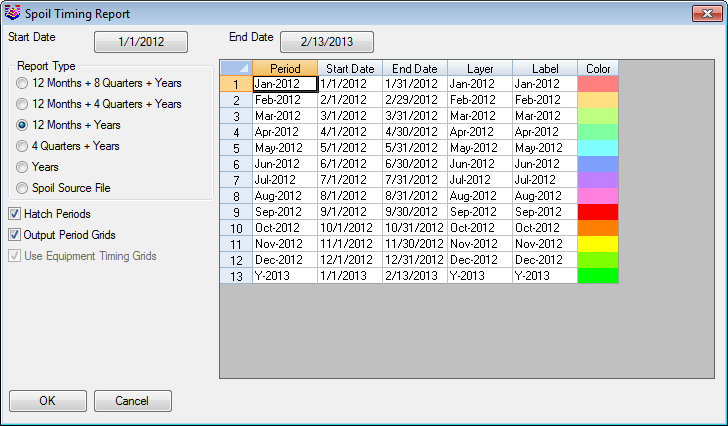

Spoil Calculation Output

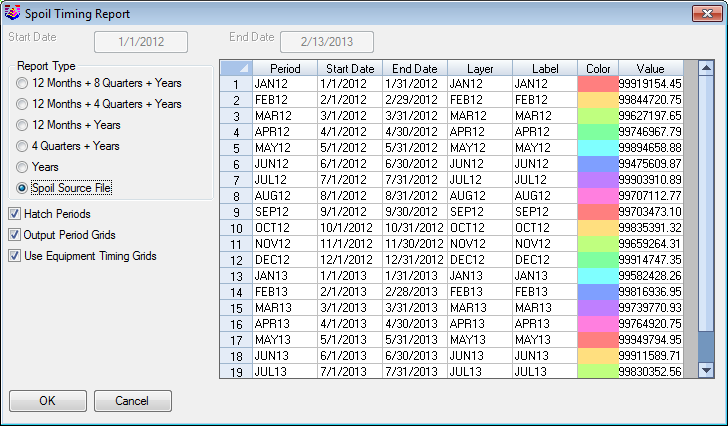

After clicking the ‘Calculate’ button, you will see the dialog

shown below. This allows you to set the type and appearance of the

text and timing report.

The Report Type will set the time periods for the timing report.

The spreadsheet will be automatically updated based on the selected

report type. The Layer, Label, and Color columns may be manually

updated, but the Period, Start Date, and End Date columns are

fixed. If the Spoil Source File report type is selected, the

periods will be set by the .spo file created in Surface Equipment

Timing. This option will also enable the Use Equipment Timing Grids

option, which will merge the spoil timing output grids with a .gsq

file created from the Surface Equipment Timing command (shown

below).

- Hatch Periods: This option will allow you to hatch the

time periods with a solid fill color. If this option is turned off,

the timing map will only show outlines and labels of the timing

periods.

- Output Period Grids: This option will output grid files

representing the surface at various time periods. These grids can

be used to review the development of the mine area.

- Use Equipment Timing Grids: This option will merge the

grid files created with the Output Period Grids option with a .gsq

file created from Surface Equipment Timing. This can be used for

detailed review of the surface development, showing the timing and

locations of material movement.

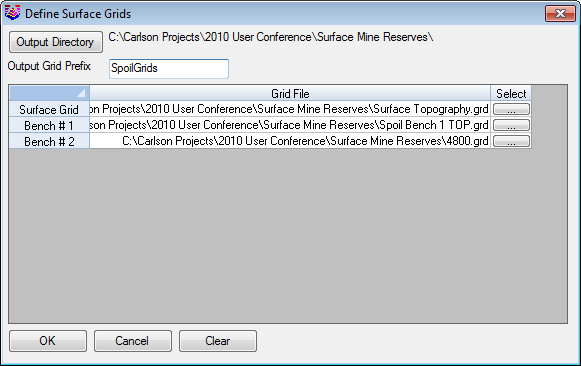

If you use the Output Period Grids option, you will see the Define

Surface Grids dialog after clicking OK (shown below). This dialog

allows you to set the surfaces which define the existing ground and

bench surfaces of the spoil piles.

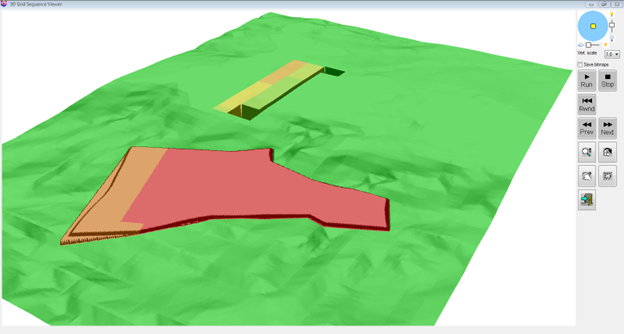

If you use the Use Equipment Timing Grids option, you will be

prompted to select a .gsq file to update. Note that you must have

an existing .gsq file for this option. This command will merge the

output surface grids with the .gsq file at the respective time

periods, which can be saved as a new .gsq file. This will represent

the full mining progression, showing the advance of the pits, and

the following of the spoil and dumps.

Example

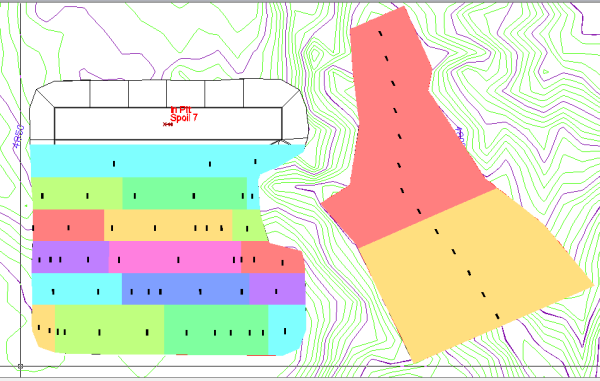

The below plan view map is hatched with the color period blocks to

illustrate where each spoil is placed in each period.

Viewing the new .gsq file with the View 3D Surface History command

will show the mining progression with the spoil fills.

Using the Report Formatter can export the report directly into

Excel. An example Excel dump is shown here.

Keyboard Command: timespoil

Prerequisite: SPO file from Surface Mine Reserves or Surface

Equipment Timing, spoil polylines with direction, and haulage

fleet.

Pulldown Menu Location: Spoil in Surface Mine Module