Surface Production Timing

This command is used for production based timing of a mineplan

to see the mine progress when defining production by time period.

It is sometimes referred to a pre-scheduler, prior to running

Surface Equipment Timing to get an estimate of mine progression.

There are 3 steps needed to prepare for Production Timing as shown

in the flow chart below. First, the mining model needs to be set up

in the Geologic Model file (PRE). This could also be the geologic

model. Next, there must be named, Carlson pit polylines

representing the mine plan. Finally, the pits lines must have

direction assigned for mining. Once these 3 items are created, the

command may be run. This command does not use highwall angles or

laybacks. It loads the mining model and vertically intersects it

with the directioned pits to obtain timing blocks.

Make Geologic Model File ----> Create Named

Carlson Pits ----> Assign Directions to Pits ----> Surface

Production Timing

The first step is to choose the Geologic Model file to process.

After it is selected, the first dialog box appears with some

initial settings. The Key Strata Recovery can be entered in the

window with Set Value, or can be set By Strata Definitions, where

it will refer to the Strata Definition File created with the Define

Strata command, or the recovery can be an attribute grid surface

found in the geologic model, with the attribute name of REC, which

may be customized. The grid would need to contain values from 0-100

for recovery. Each strata can have it's own recovery with the

second two options. The Key Strata Density is set in the same way.

Either by entering it here, or as defined in the SDF file. The

units are either pounds/cubic foot or kg/cubic meter, depending on

US units or metric units in the drawing. Finally, the Source of

Bottom Surface Model can be set here. If Strata Model is chosen,

then the routine will use all seams from the surface topography

down to the lowest strata surface in the Geologic Model file. If

Surface File is selected, then volumes will only be calculated from

the topography down to that bottom surface grid or TIN file, which

could be a flat bench elevation for example, or a complex benched

pit with many levels. A file-select window will appear next, to

choose the grid or TIN if that option is used.

Next, after selecting the pits and the mining project file, the

Surface Production Timing window appears as follows.

The first step is to select pits and move them over to the

Assignment box on the left with the Assign button. Following is a

detailed description of each item in the dialog box.

- Do Earlier / Do Later:

These buttons move the pits up or down in the Assignment

window.

- Remove, Remove All:

These buttons will move either the selected pit, or all pits from

the Assignment window to the Unassigned Pits window

- Assign: This button

will move the highlighted pits from the Unassigned window to the

Assignment window.

- Select All: This is a

quick way to highlight all pits in the Unassigned Pits.

- Inverse sorting: If

this is checked, then the pits will appear in reverse order in the

Unassigned Pits window, otherwise they are in alphabetical and

numeric order.

- Screen Pick: Allows for

manual selection of pits in plan view with a cross-hairs. Simply

place the cursor in the pits and pick in the order to mine. Hit

enter when done. The selected pits should appear in the Assignment

window in the order they were picked.

- Report pits on one row:

This option is for report formatting. If this is checked, the

report will have one row per time period and all strata quantities

and qualities will follow on that row, each in their own column. If

this is not checked, then each strata will be in its own row in the

report, with its quality to follow. This is option is usually not

selected.

- Use property

boundaries: There must be named property boundaries on

screen for this option. Production timing will automatically detect

them and break out the production by owner and property if

desired.

- Draw timing blocks: One

of the main items of output from this command. It draws the periods

as blocks of solid fill or any hatch pattern inside the pits in

plan view. They are colored by period. As they are being drawn, the

direction and progress of the mineplan can be seen for

review.

- Draw distinct outline:

This is very similar to the timing blocks, except that they are

just closed polylines with no fill or hatch. They are in their own

color, and optionally, layer. They can be used later for further

reserve calculations, or to save the mineplan without hatch or

fill.

- Draw labels: This

option places the period name in the block or outline. It is either

the user defined label, or will just use "Period1", "Period2"

etc.

- Text autosize: If this

is selected, the text will be automatically sized to fit the size

of the block outline. Otherwise, the text might be too large for

some of the smaller blocks.

- Draw labels

length-wise: Selecting this option orients the text

lengthwise to the long axis of the block outline. Otherwise it will

be placed horizontally.

- Text Size: Enter in the

text size for labels. It will use this if Text Autosize is not

selected.

- Text Style: Enter the

AutoCAD Text Style for labels and legend.

- Draw Legend: Select

this option to draw a legend of the timing blocks showing the color

and the name of the period. It will ask to pick the legend

position.

- Legend Scale: Enter in

a legend scale size to size the legend.

- Layers by Period: This

option will create a new layer for each time period and draw the

blocks and outlines in those layers.

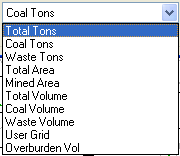

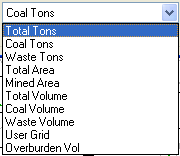

- Production Table Type:

This is a very important setting that needs to be selected for the

target material. There are 10 choices to use for production

targeting. Most common are Key Tons and Overburden Volume, but

others are available. Total Tons converts all strata to tonnages

and mines them accordingly. The NonKey density is set in a window

that appears as soon as Run is selected. Key Tons are tons of the

combined key material, which name is set in Configure /Mining.

Waste Tons will combine all NonKey strata, calculate the tons for

it and target that tonnage for production. Mined Area will target a

defined area in square feet or meters for production. Total Volume

will combine all strata, both Key and NonKey and target the total

CY or CM. Key Volume or Coal Volume will target the CY or CM of all

Key strata in the selected Geologic Model file. Waste Volume

combines all NonKey strata and targets the CY or CM of them. User

Grid will take any grid and target total quantities for production.

An example of this would be a power plant that wants to target

total BTU. The grid to select would be total BTU/area. Finally, the

Overburden Volume will take just the first NonKey strata in the

Geologic Model and target that, but still report any additional

NonKey seams below it.

- Stop at Last Period: If

this is checked, then the routine will stop after the last period

entered in the Production Table. If it is not checked, then it will

continue with the last target amount all the way through the last

selected pit polyline.

- Production Table: This

is the screen to set the production amount and time period or date.

The first column is the amount to target. This is what you have

selected under Production Table Type. The second column is the

color for that period. The next column is the hatch pattern for the

block. If it is a hatch pattern other than SOLID, then it must have

a scale factor, set in the next column. the AutoCAD Layer is set in

the next column and finally, the Label is set in the last column.

This can be anything from dates, to owners and areas. If the Labels

are left blank, then it will fill in labels such as Period3,

Period4, or month or year, etc. The Clear button will clear the

entire screen. There are Save and Load buttons for easy retrieval

of the CQT files.

- Undo: This will undo a

previous run, removing the colored blocks and outlines.

- Run: This is the button

to start the actual timing and sequencing of the pits. After the

Production Table and all the settings are good, then choose

Run.

- Finish: After the

blocks are drawn and the Surface Production Timing window comes

back, selecting the Finish button will start the calculations and

generate the quantities and qualities in the Report Formatter. Here

items are selected to appear in the report and exported to a file,

such as Excel or Access.

A finished map with the blocks drawn on it and the

corresponding report are shown here. In this example, the amount

was set to 225,000, then 250,000 tons. In the report, notice the

accuracy of the tons. Most are within a couple of hundred tons.

Pulldown Menu Location:

Surface Mine Module - Reserves/Timing

Pulldown Menu Location:

Surface Mine Module - Reserves/Timing

Keyboard Command: calcplan

Prerequisite: Timing pit polylines

Pulldown Menu Location:

Surface Mine Module - Reserves/Timing

Pulldown Menu Location:

Surface Mine Module - Reserves/Timing