Haul Cycle Analysis

This command is used for detailed analysis of haul routes using

various haul trucks to determine either 1) the required truck fleet

required to meet a target production or 2) the attainable

production based on a given haul fleet. This command requires the

user to have executed the Haul Road Manager to define the haulage

route. Although optional, it is recommended to define and customize

truck parameters using the Haul Fleet Manager command to ensure the

most accurate results. The first section of this document discusses

the basic use of this routine, while the second section discusses

the actual calculations that are performed to analyze the haul

cycle.

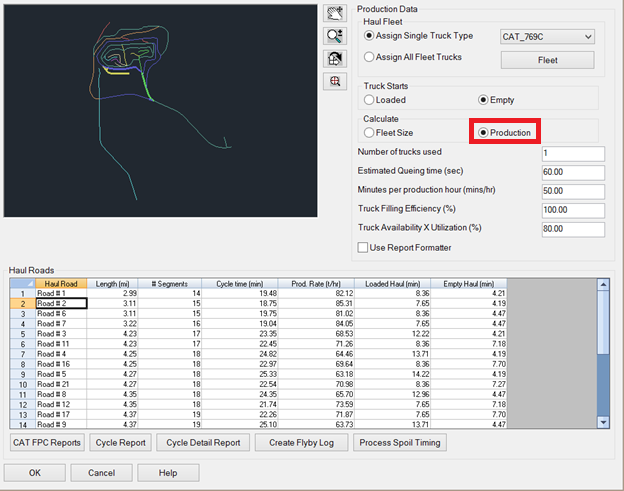

Basic Use

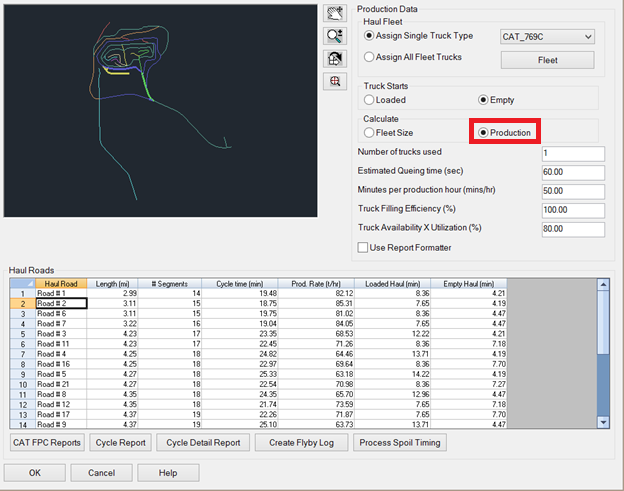

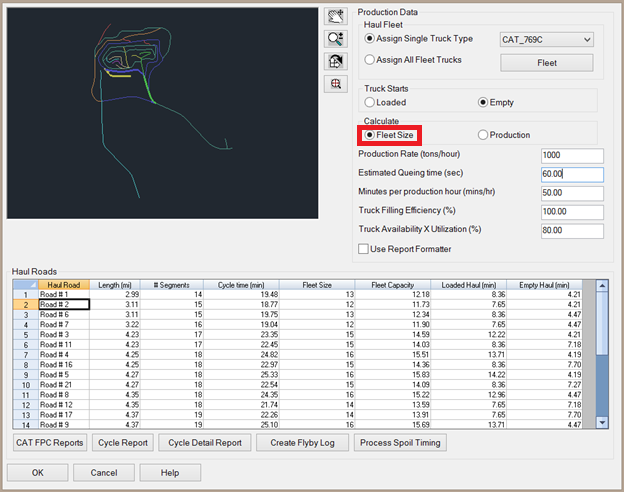

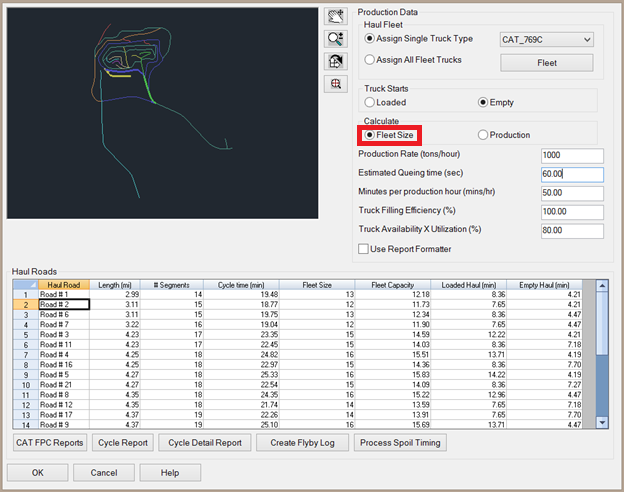

First, you will be prompted to select the start and ending points

of the haul road to be considered. The dialog that appears will

show a spreadsheet view of all potential routes between the

starting and ending point which will be sorted by distance in

increasing order. The dialog will change slightly depending on the

‘Calculate’ option selected (either Fleet Size or Production).

- Preview Window: highlights the currently selected haul

route. This window works very similar to the 3D Viewer Window.

Using the four icons next to this screen, you can pan, zoom,

rotate, and zoom to the extents of the haul route.

- Production Data Section: allows you to choose the type

and amount of haul trucks to be used for the cycle analysis. The

‘Assign Single Truck Type’ option will allow you select one of the

trucks defined in the Haul Fleet Manager library. The ‘Assign All

Fleet Trucks’ option will use the types and amounts of trucks

defined in the same library. Clicking the ‘Fleet’ button will allow

you to edit this library. Using the ‘Assign All Fleet Trucks’

option will only allow you calculate the attainable production

rate. For more information on the Haul Fleet Manager, see the

appropriate section of the help manual.

- Truck Starts option: allows you to specify if the

selected starting point represents the loading or the dumping point

of the route.

- Calculate option: changes the routine to calculate

either the required fleet size based on a production target, or the

attainable production target based on the haul fleet.

- Production Rate: This value can be set when calculating

the required fleet size. This sets the target production the haul

fleet must meet.

- Number of trucks used: This value can be set when

calculating the attainable production when using the ‘Assign Single

Truck Type’ option.

- Estimated Queuing time: This the estimated time that the

truck must wait in line at either the loading or the dumping point

per cycle (25 second wait at the loading point and 15 seconds at

the dumping point would be a total Estimated Queuing time of 40

seconds).

- Minutes per production hour: This is the expected

working time per hour. This is essentially a measure of work

efficiency, and should therefore account for variable delays due to

factors such as:

-

- Excavating equipment delays

- Personnel delays

- Climate delays

- Truck Filling Efficiency: This is the fill percentage of

the truck. A 90% filling efficiency applied to a truck that is

intended to carry 100 tons will only carry 90 tons per cycle.

- Truck Availability X Utilization: This value is

multiplied by the Minutes per Production Hour to determine the

total working time of the truck. It is intended to account for

fixed delays and mechanical availability of the truck. For a truck

listed as working 50 minutes per production hour, an Availability X

Utilization value of 90% will result in only 45 working minutes per

hour.

- Use Report Formatter: This option will allow you use the

Report Formatter for the Cycle Report and the Cycle Detail Report

to customize the reported information.

Reports

The Haul Cycle Analysis command is very quick and dynamic. Whenever

a value is edited, the results in the spread sheet view will be

automatically updated. These results can be reported in a variety

of formats as discussed below.

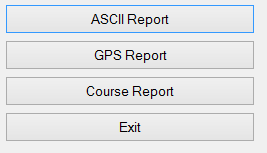

CAT FPC Reports: This option will allow you to export one of

three report types: ASCII, GPS, and Course.

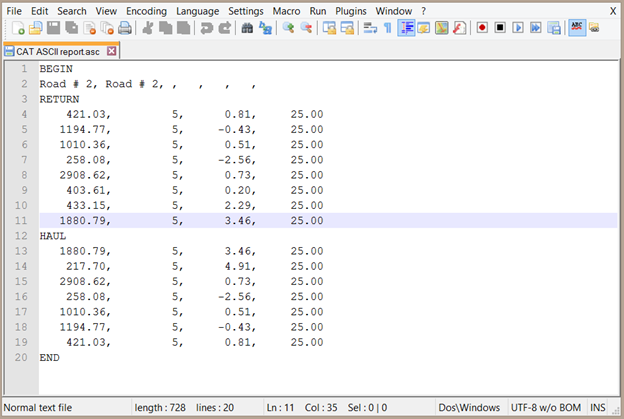

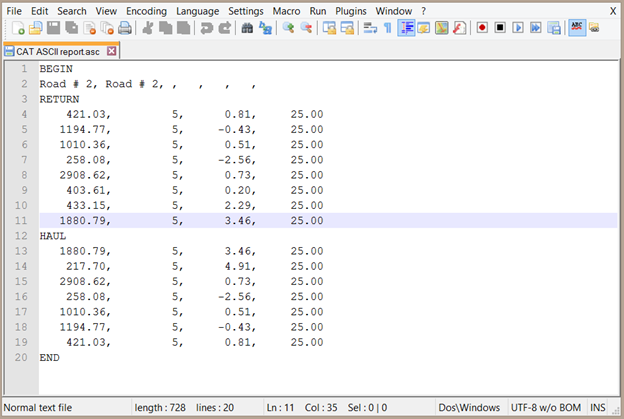

The ASCII report will export the segment distance, the rolling

resistance, the slope, and the speed of the truck along each

segment into an .asc file as shown below:

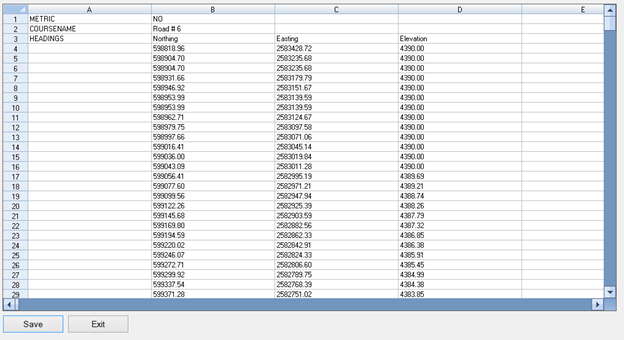

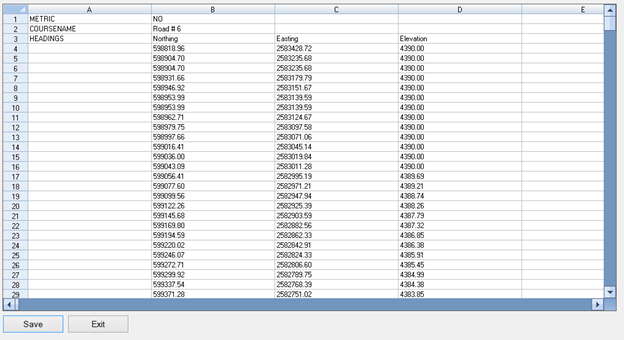

The GPS report will export the coordinates and elevation of the

haul road at each vertex representing the road. This report can be

saved as an Excel spreadsheet (.xls file) as shown below:

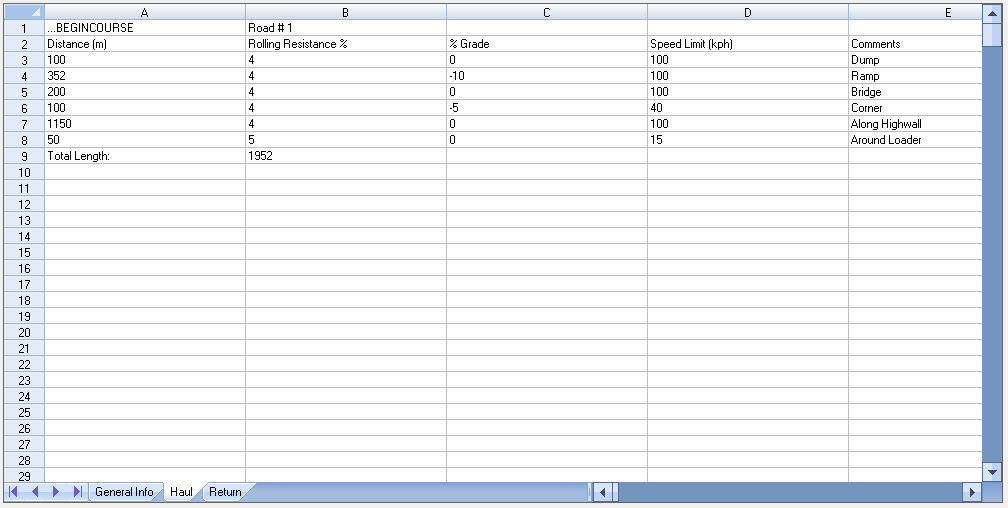

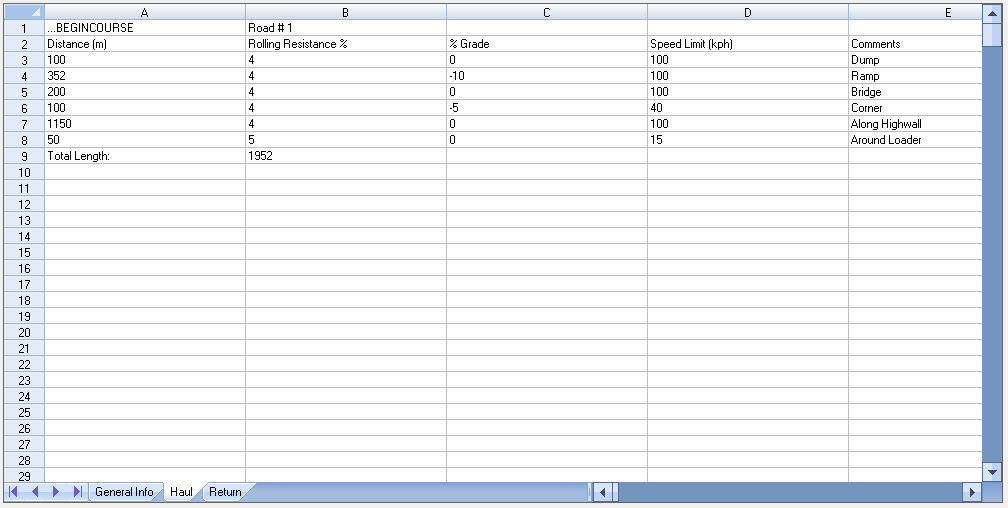

The Course Report is reported in a spreadsheet with three tabs:

General Info, Haul, and Return. This file can also be saved as an

Excel spreadsheet, as shown below:

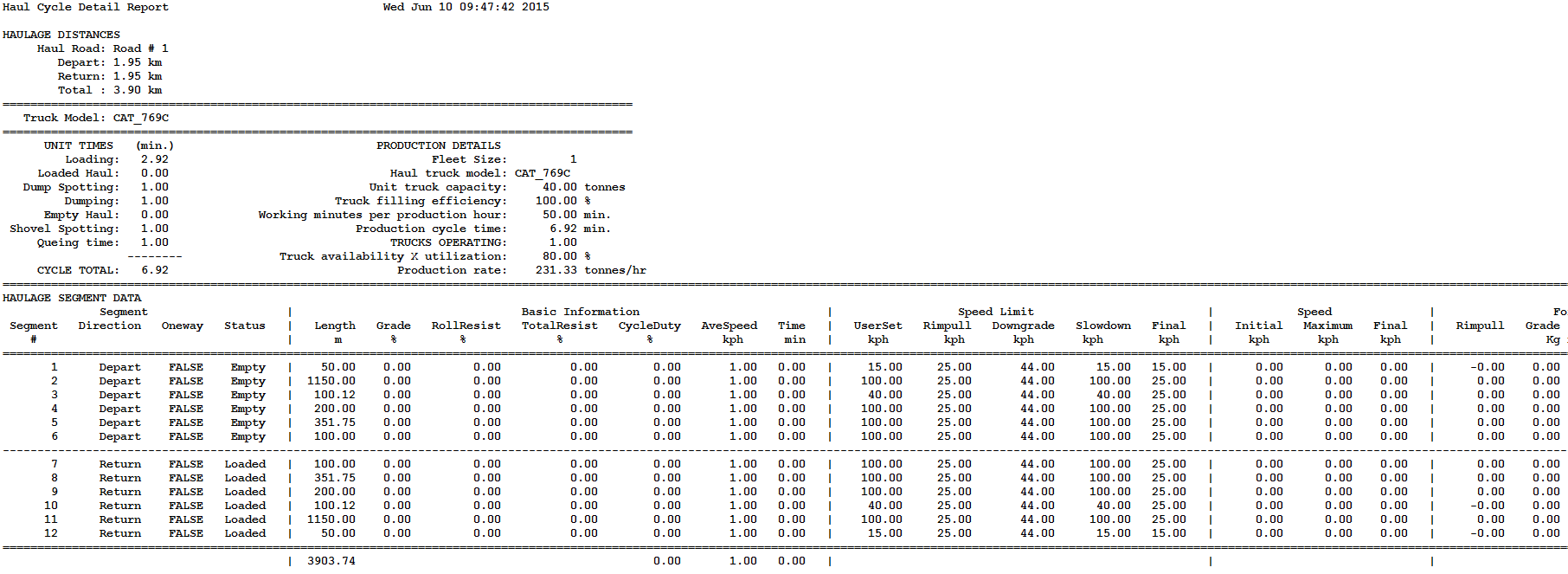

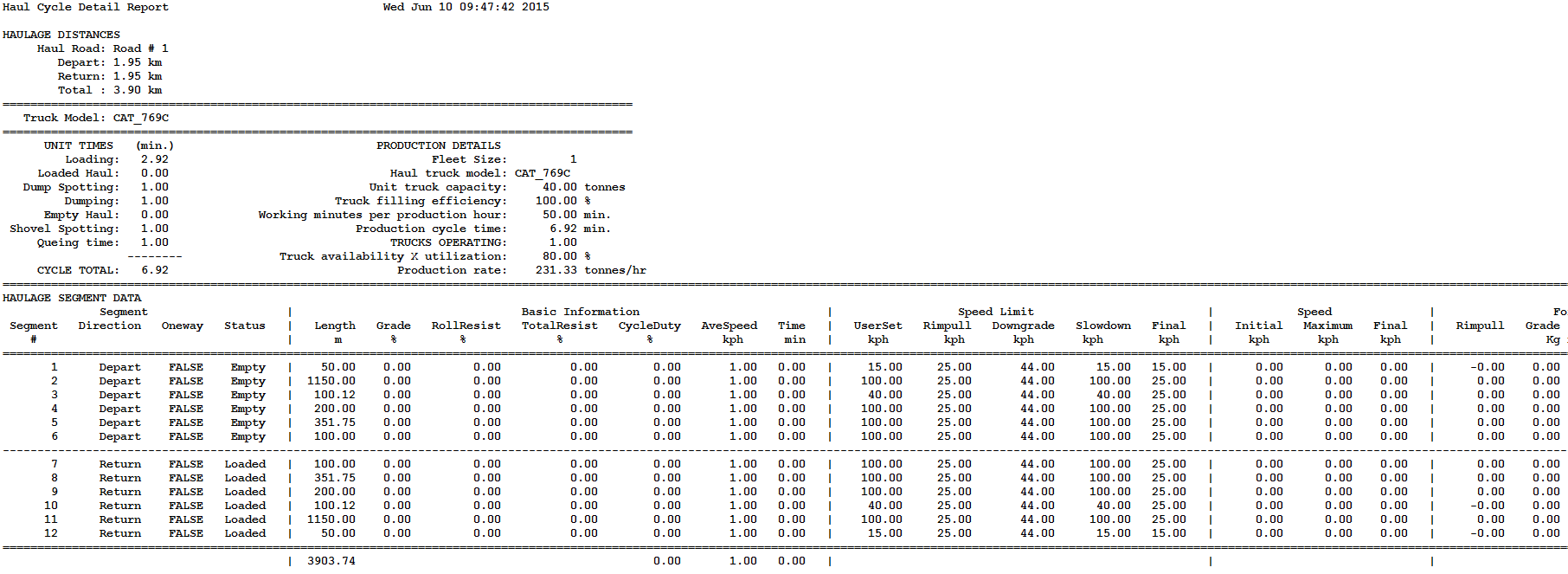

Cycle Report: This report gives basic information about the

haul cycle.

Cycle Detail Report: This report provides more detailed

information about the haul cycle, which in addition to the

information in the standard report, provides information about the

transition of speed along each segment, the rimpull applied on each

road, and detailed information about the sub-segments which are

used in the calculations.

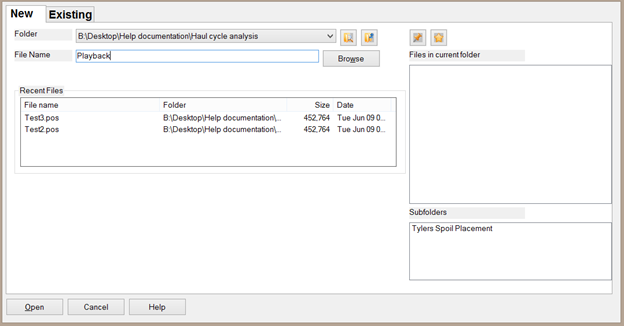

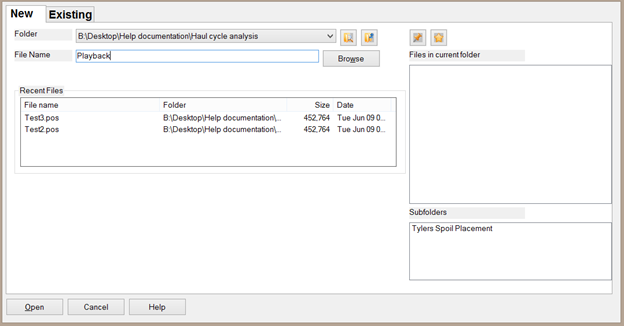

Create Flyby Log: This option will create a .pos file which

can be reviewed with the Surface 3D Flyover command in the Civil

module. You will be prompted to enter a road width, then you will

be allowed to specify the file name.

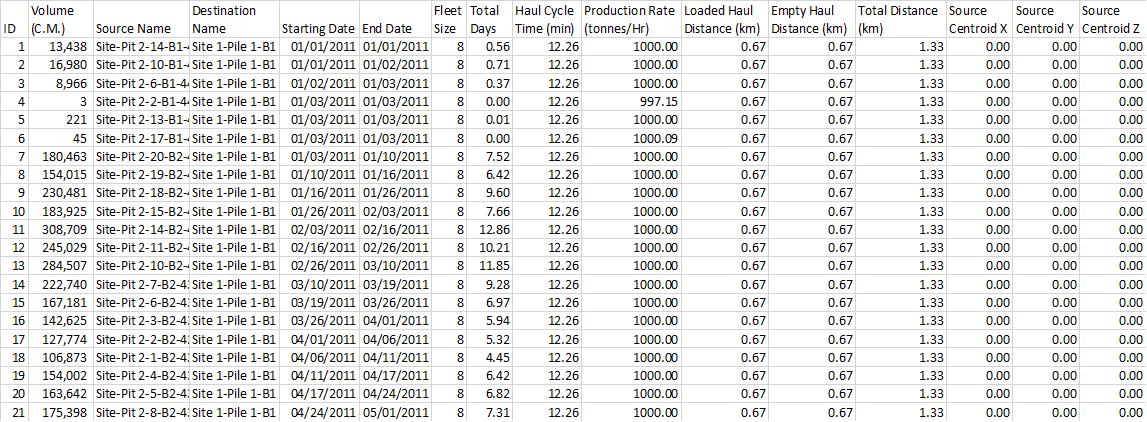

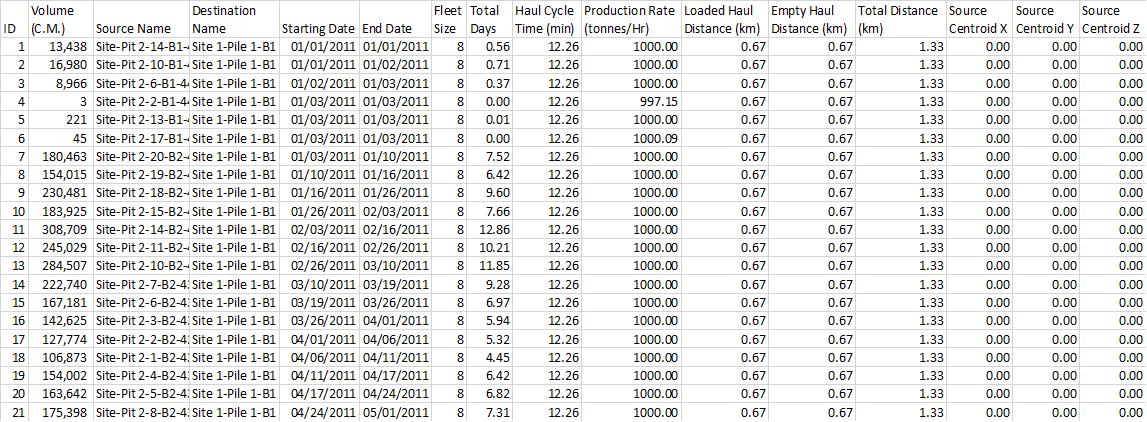

Process Spoil Timing: This command will perform a timing

analysis on an exported .sph file from Spoil Placement Timing. This

will give a more detailed analysis of the haul cycle during each

time period of the spoil placement. An example report is provided

below:

Calculation Methods

A good planner will be cautious about blindly accepting

calculations. For this reason, the following section details the

logic and calculations used in Haul Cycle Analysis so that the user

can fully understand how the routine works.

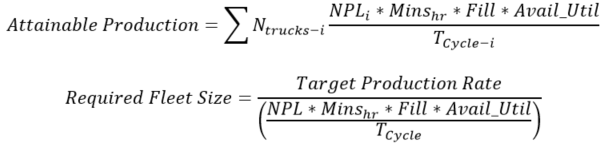

As previously stated, this routine seeks to calculate either the

attainable production based on the truck fleet or the fleet size

required to meet a target production. Actually determining these

values is rather simple once to the true cycle time has been

calculated. However, calculation of the cycle time considers many

factors. The first sub-section of this section details how the

program calculates cycle time. The following sub-section details

how the attainable production and required fleet size are

calculated based on the calculated cycle time.

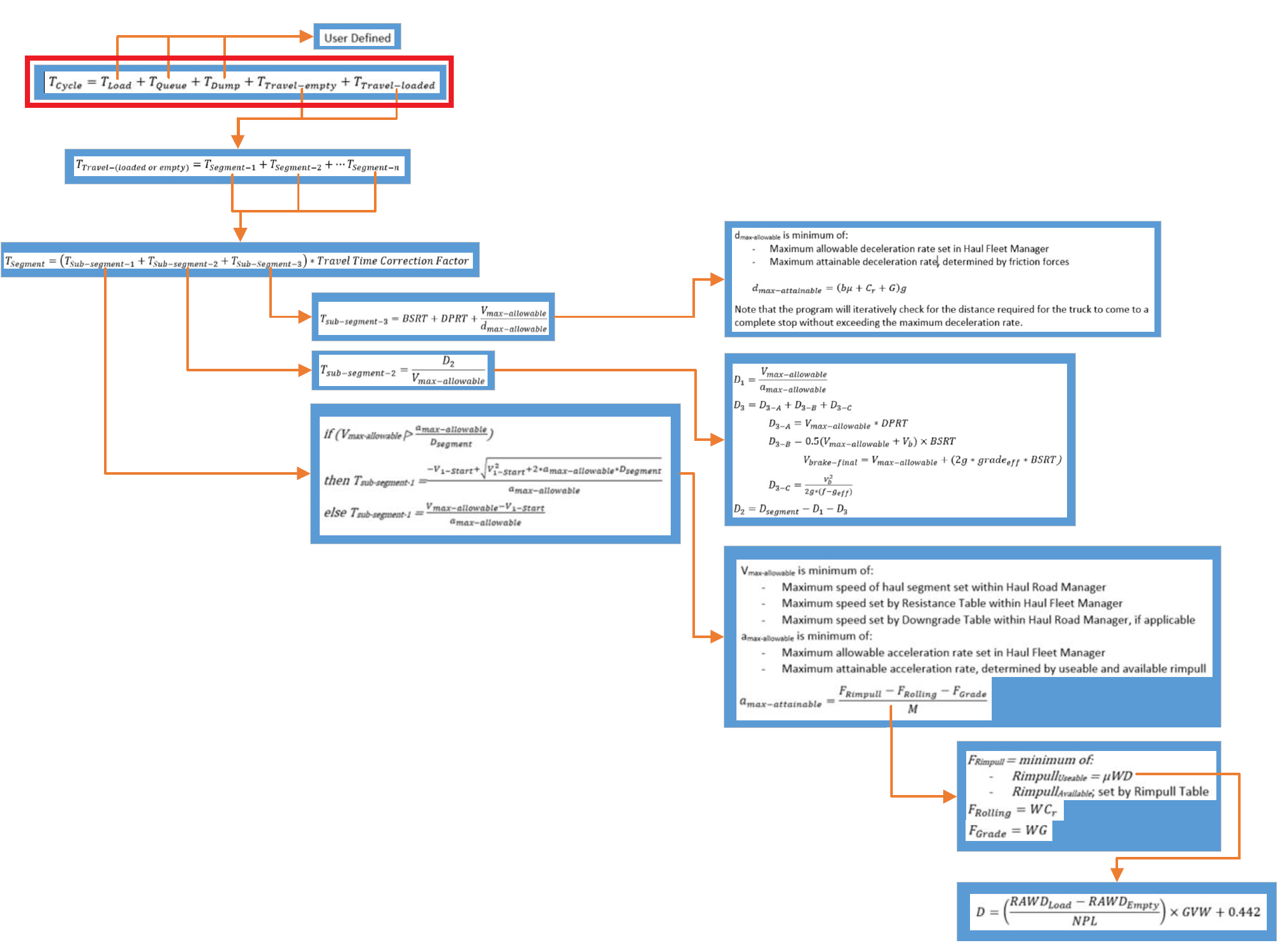

Calculation of Cycle Time

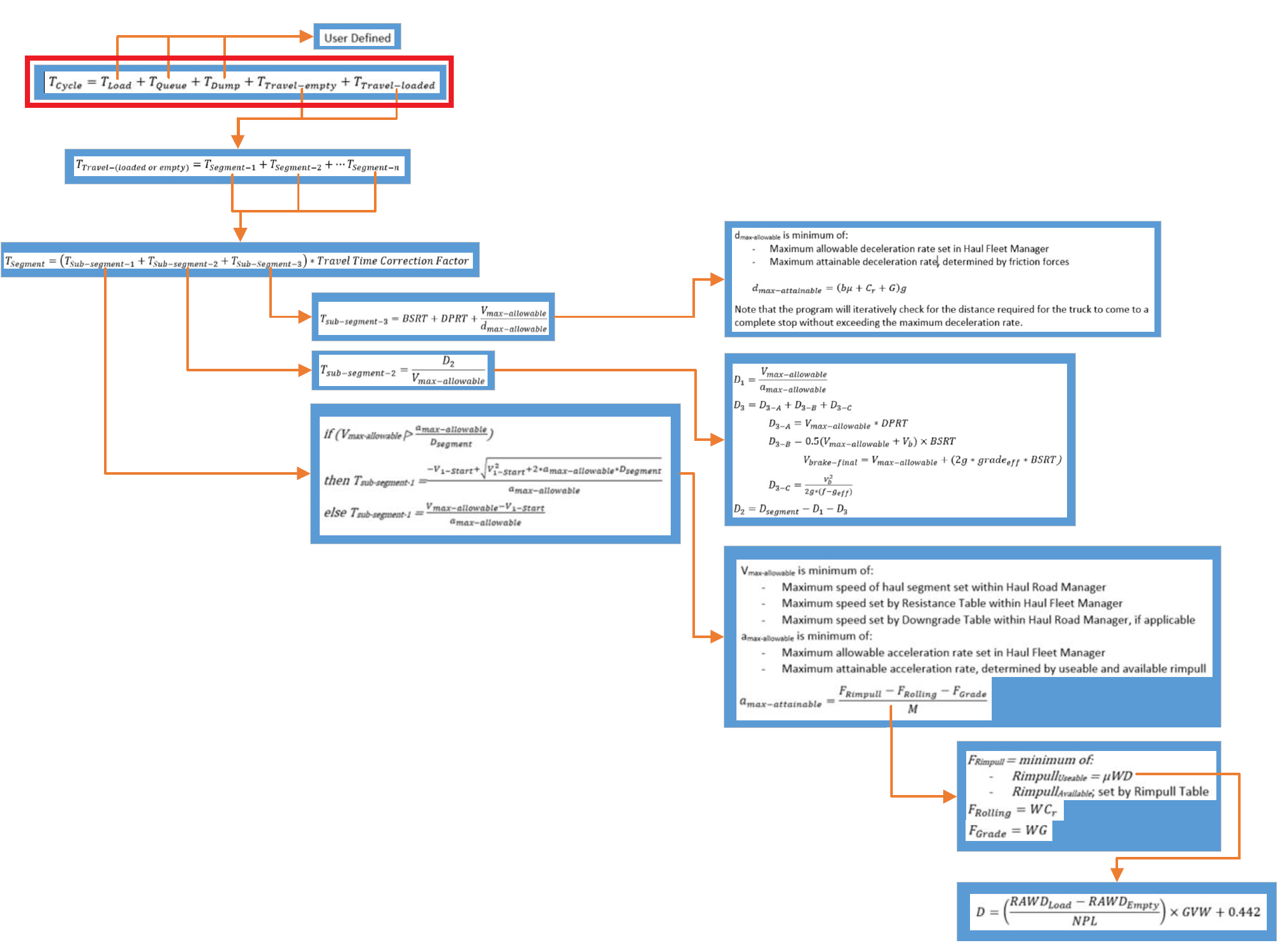

The diagram shown below is visual outline of the equations used to

calculate the haul cycle time. This is provided to allow for a

better understanding of how Haul Cycle Analysis uses input

variables to determine various operating parameters. Note that this

diagram is simplified, and does not detail all of the logic used in

the actual routine.

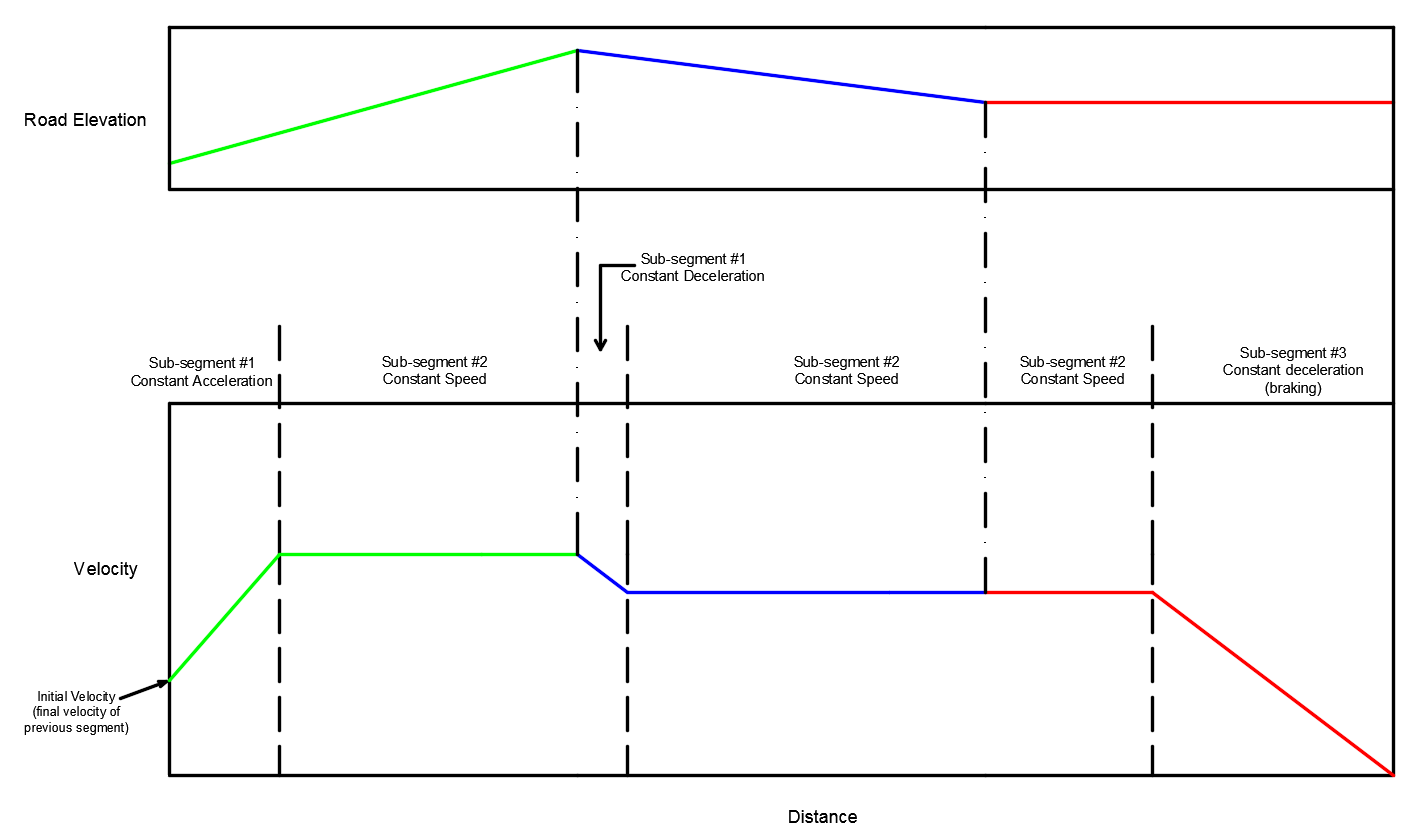

The total haul cycle time can be calculated with the following

equation:

where

where

- TCycle is the total cycle

time

- TLoad is the time required to

load the truck

- TTravel-loaded is the time

required for the truck to travel from the loading point to the

dumping point

- TQueue is the total estimated

queuing time (sum of queuing time at both the loading point and the

dumping point)

- TDump is the time required

for the truck to dump its payload

- TTravel-empty is the time

required for the truck to return to the loading point from the

dumping point

Three variables, TLoad, TDump, and

TQueue, are manually entered. The remaining

variables, TTravel-loaded and

TTravel-empty, are calculated similarly to one

another, but with different values based on the road profile and

truck specifications for loaded and empty scenarios.

TTravel-loaded and TTravel-empty are

calculated with the following formula:

TTravel-(loaded or

empty)=TSegment-1+TSegment-2+⋯TSegment-n

where

TSegment-1 is the travel time of

the first segment of the haul route

TSegment-2 is the travel time of

the second segment of the haul route

Etc.

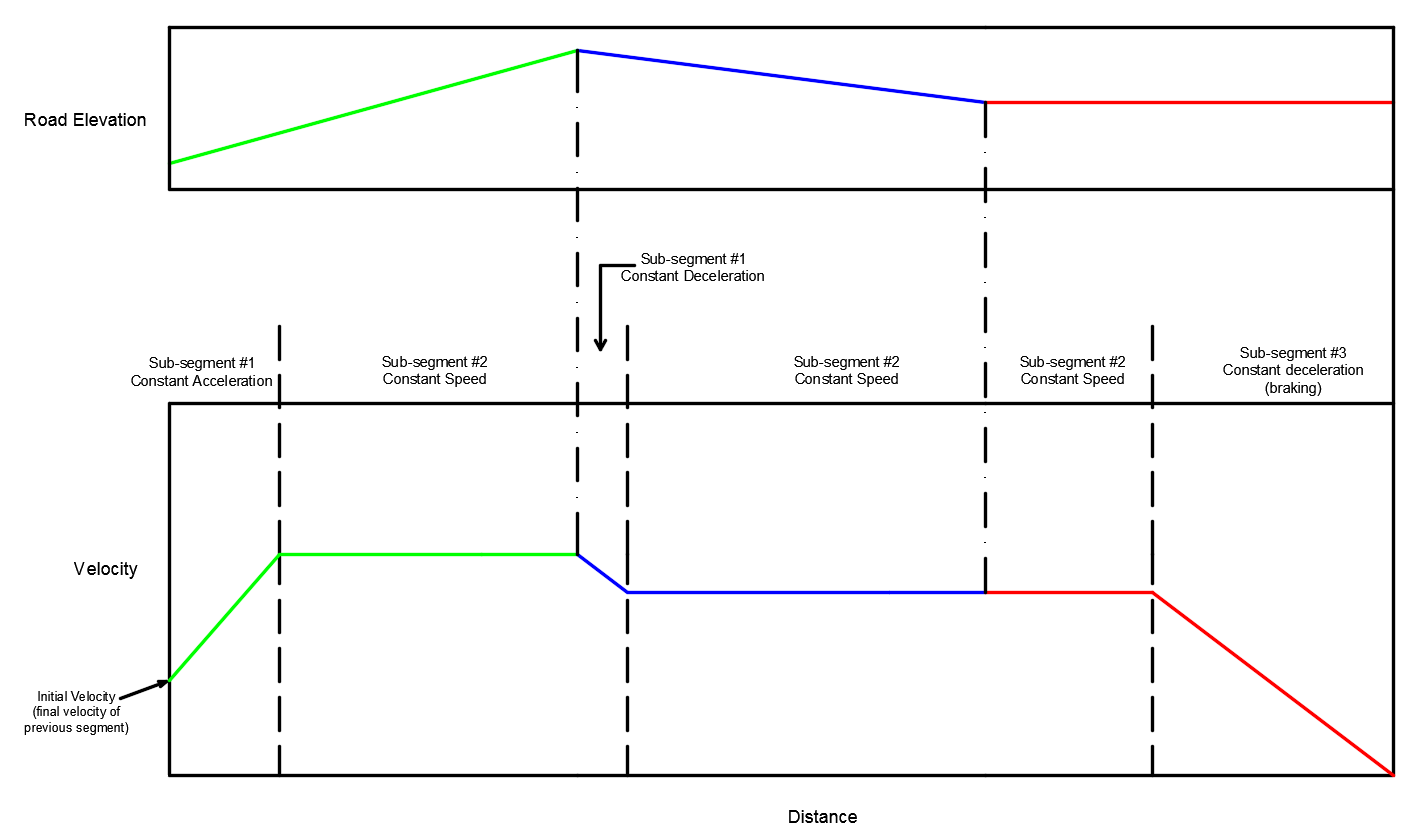

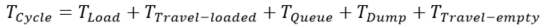

The travel time for a single haul segment will be further divided

into three sub-segments according to the following chart.

Sub-segment #1: the truck is

accelerating/decelerating at a constant rate

Sub-segment #2: the truck is traveling at

a constant velocity

Sub-segment #3: the truck is braking.

Note that sub-segment #3 is only used when the truck comes to a

complete stop.

In the below picture:

- The top portion of colored lines represent

the road profile, broken into three haul segments

- The lower portion of colored lines represent

the velocity of the truck along the haul road

- Haul Segment 1 (green line)

- Sub-segment #1 shows the truck accelerating

as it travels uphill to meet the new road speed limit

- Sub-segment #2 shows the truck traveling at

a constant velocity once it reaches the road speed limit

- Haul Segment 2 (blue line)

- Sub-segment #1 shows the truck decelerating

as it starts to travel downhill to meet the new road speed

limit

- Sub-segment #2 shows the truck traveling at

a constant velocity once it reaches the road speed limit

- Haul Segment 3 (red line)

- Sub-segment #2 shows the truck traveling at

a constant velocity. It is traveling at the speed limit when it

approaches Haul Segment 3.

- Sub-segment #3 shows the truck braking as

the truck comes to a complete stop.

The total travel time for a haul segment is simply a sum of the

sub-segment travel times, as shown below:

TSegment=(TSub-segment-1+TSub-segment-2+TSub-Segment-3)

The travel time of each sub-segment is calculated using the

following formulae:

where

- TSub-segment-1 is the travel

time of sub-segment #1

- Vmax-allowable is the maximum

allowable truck velocity along the haul segment

- V1-Start is the truck

velocity at the start of sub-segment #1, equal to zero at the

beginning of the haul route

- amax-allowable is the maximum

allowable acceleration of the truck on sub-segment #1

- TSub-segment-2 is the travel

time of sub-segment #2

- D2 is the distance of sub-segment #2

- TSub-segment-3 is the travel

time of sub-segment #3

- BSRT is the Brake System Response Time

- DPRT is the Driver Perception Response

Time

- dmax-allowable is the maximum

allowable deceleration rate of the truck

Sub-Segment #1 Supplement

Vmax-allowable is minimum

of:

- Maximum speed of haul segment set within

Haul Road Manager

- Maximum speed set by Resistance Table within

Haul Fleet Manager

- Maximum speed set by Downgrade Table within

Haul Road Manager, if applicable

amax-allowable is minimum

of:

- Maximum allowable acceleration rate set in

Haul Fleet Manager

- Maximum attainable acceleration rate,

determined by useable and available rimpull

Note that a truck’s velocity does not necessarily have to increase

during sub-segment #1. If a truck enters a haul segment at a speed

which exceeds the maximum allowable velocity for the haul segment,

then sub-segment #1 will refer to a decelerating situation.

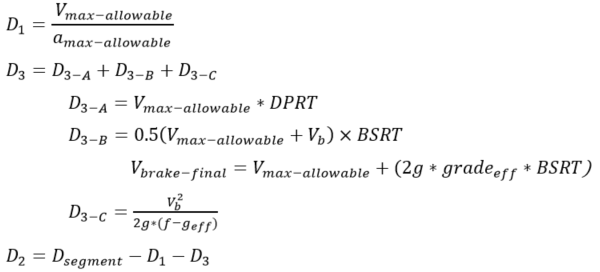

Sub-Segment #2 Supplement

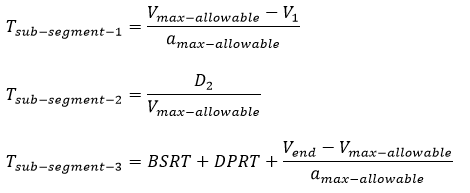

In the final report, sub-segment distances will be reported as D1,

D2, and D3, which refer to the distances of the respective

sub-segments. The distance for each sub-segment is calculated as

shown below. Here it is also important to note that the sub-segment

#3 is further divided into three sections which represent A) the

time required for the driver to realize that a stop is required, B)

the time from when the driver first applies the brake to the time

when the brake system applies the full braking force, and C) the

time required for the truck to stop once the full braking force is

applied.

Note that in many situations one or two of these sub-segments will

not be used in the final calculations. For example, if a truck

enters a new haul segment and does not need to

accelerate/decelerate to meet the speed limit, the distance and

travel time for sub-segments #1 and #3 will be zero. As another

example, sub-segment #3 will only be used when the truck is braking

to a complete stop.

where

- D1 is the distance of

sub-segment #1

- D2 is the distance of

sub-segment #2

- D3 is the distance of

sub-segment #3

- D3-A is the distance of

sub-segment #3, section A

- D3-B is the distance of

sub-segment #3, section B

- D3-C is the distance of

sub-segment #3, section C

- DSegment is the length of the

current haul segment

- Vb is the truck velocity at

the end of the Brake System Response Time

- g is the acceleration due to gravity

- f is the coefficient of friction available

for braking (

- geff is the effective grade,

which is a sum of the road grade and the rolling resistance of the

road on the tires

Sub-segment #3 Supplement

dmax-allowable is minimum

of:

- Maximum allowable deceleration rate set in

Haul Fleet Manager

- Maximum attainable deceleration rate,

determined by friction forces

Note that the program will iteratively check for the distance

required for the truck to come to a complete stop without exceeding

the maximum deceleration rate.

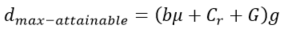

Max Truck Acceleration/Deceleration

Both sub-segments #1 and #3 must check for the maximum allowable

acceleration/deceleration rate, and one of the rates to be

considered is the rate limited by friction, also referred to as the

useable rimpull. The below equations show how the

acceleration/deceleration rates are calculated.

As previously shown, Haul Cycle Analysis analyzes truck movement by

constant acceleration/deceleration along sub-segments and sections

of sub-segments. For this reason, the acceleration of the truck can

be defined by scalar quantities in Newton’s Second Law of motion,

shown below and simplified:

where

F is the sum of all forces acting on the

truck

M is the mass of the truck

amax-attainable is the maximum

possible acceleration of the truck

FRimpull is the effective rimpull

force (minimum of available rimpull and useable rimpull force)

FRolling is the force of rolling

resistance, which is set within the Haul Road Manager for each haul

segment

FGrade is the grade resistance

force, defined as positive for uphill and negative for downhill

movement

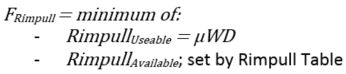

FRimpull

Available Rimpull is determined from standard Rimpull Curves

provided by truck manufacturers. This data is entered into the Haul

Fleet Manager in a tabular format in the Rimpull Table. From the

entered values, the program will determine the available rimpull at

various operating speeds.

Useable rimpull is the maximum force the truck can apply before the

tires start to slip on the road. This value is calculated with the

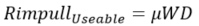

following equation

where

- RimpullUseable is the useable

rimpull force

- μ is the traction coefficient between the

road and the tires, which is set in the Haul Fleet Manager

- W is the truck weight

- D is the ratio of the truck weight on the

rear axle

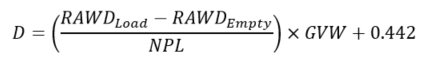

Furthermore, D can be calculated with the following equation

where

RAWDLoad – drive (rear) axle

weight distribution percentage in loaded condition, expressed as a

decimal

RAWDEmpty – drive (rear) axle

weight distribution percentage in empty condition, expressed as a

decimal

NPL – nominal payload

GVW – gross vehicle weight; note that will not

always equal the loaded truck weight

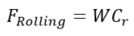

FRolling

Where

Cr is the haul segment rolling resistance, expressed

as a decimal; this is set in the Haul Road Manager

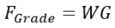

FGrade

Although this calculation does not perfectly calculate the

resistive/assistive force due to the grade of the road, the

difference between the calculated value and the ‘true’ value is

considered insignificant. Once the maximum possible acceleration of

the truck has been calculated, this value is compared to the

maximum acceleration limit set in the Haul Fleet Manager. The

minimum of these two values is used for the calculation of the

distance and travel time of sub-segment #1 for each haul

segment.

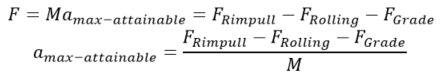

Maximum Deceleration

When a truck slows down, it is limited to using the lesser of two

possible deceleration rates. One rate is defined directly in the

Haul Fleet Manager. The other rate is calculated based on Newton’s

Second Law using the below formulae:

where

- FAvailable is the total

available retarding force

- dmax-attainable is the

maximum attainable retarding deceleration rate

- M is the mass of the truck

- FRetard is the retarding

force

- FRolling is the rolling

resistance force

- FGrade is the grade

resistance force

- b is the braking reliance on traction

- μ is the traction coefficient

- Cr is the rolling resistance

coefficient

- G is the road grade; uphill is positive,

downhill is negative

- g is the acceleration due to gravity

- W is the truck weight

Calculation of Required Fleet Size and Attainable

Production

Once the total cycle time has been calculated, the calculation of

the required fleet size/attainable production is very simple. The

calculations for these values are shown below

Where

- NTrucks-i is the number of

trucks of a specific model

- NPLi is the nominal payload

of a specific truck model

- Minshr is the minutes working

per production hour

- Fill is the truck filling efficiency

- Avail_Util is the truck availability

multiplied by the truck utilization

- TCycle-i is the truck cycle

time for a specific truck model

Note that the total attainable production is the sum of each

attainable production rate of each truck in the haul fleet.

References:

Parreira, Julianna. "An Interactive Simulation Model to Compare an

Autonomous Haulage Truck System with a Manually-Operated System."

Diss. THE UNIVERSITY OF BRITISH COLUMBIA (VANCOUVER), 2013.

Print.

U.S. Department of Labor. MSHA Haul Road Inspection Handbook. June

1999. Handbook Number PH99-I-4.

Prompts

Delay: Intersection

Merge (will be a pre-named delay name)

[near on] Pick start point on Haul Road: select where the

truck will begin, usually where it gets loaded at.

[near on] Pick end point on Haul Road: select where the

truck will end, usually where it unloads/dumps at.

Pull-Down Menu Location: Reserves/Timing in

Surface Mining

Keyboard Command: haul_cycle