Road Rehabilitation Profile

This command creates a profile that sets a road design at an

elevation to meet the specified overlay thickness along with

leveling or milling thickness. The rehabilitation profile created

by this command can then be used in Process Road Design to create

the rehabilitation design including the rehabilitation surface,

sections, quantities and linework.

The first dialog specifies the road design files. All

these settings are the same as in Process Road Design except for

the Output Rehab Profile. This profile is the output result for

this command. The difference with Process Road Design is that the

profile is an output instead of an input. Please see the Process

Road Design section of the manual for a description of the other

input files.

The first dialog specifies the road design files. All

these settings are the same as in Process Road Design except for

the Output Rehab Profile. This profile is the output result for

this command. The difference with Process Road Design is that the

profile is an output instead of an input. Please see the Process

Road Design section of the manual for a description of the other

input files. The second dialog has processing options. Again, many

of these parameters are the same as Process Road Design. The

settings specific to this command are the following:

The second dialog has processing options. Again, many

of these parameters are the same as Process Road Design. The

settings specific to this command are the following:

Rehabilitation Method: This chooses between adding a

leveling layer to the existing road or stripping the existing road

by milling or grinding.

Minimum Leveling Thickness:

This is the minimum fill thickness between the existing road and

the bottom of the overlay subgrade of the new road.

Minimum Milling Thickness:

This is the minimum cut thickness between the existing road and the

bottom of the overlay subgrade of the new road.

Overlay Thickness: This is

the depth of the overlay subgrade of the new road. This value

should match the subgrade thickness defined in the template.

Template IDs to Rehab:

These are the grade IDs from the template definition to process for

the overlay. The Select button can be used to graphically pick the

template IDs. Multiple IDs can be specified by entering the IDs

separated by commas. For example, if a road has two lanes with two

grades for overlay and the template IDs are LANE1 and EP, then

enter "LANE1,EP" in the dialog.

Example 1: Milling

In this case, the existing road will be trimmed by the specified

milling thickness.

Step 1: Define

Centerline

Use a routine from the Centerline menu to create the .CL file. For

example, for entering design plans, use Input-Edit Centerline File.

For using the geometry of a polyline, use Polyline To Centerline

File.

Step 2: Define Template

Run Design Template to create a .TPL file. In this case, the

template will be a two lane road with 12' lanes and -2% cross

slopes. That's the minimum that needs to be defined for the

rehabilitation design. The cut/fill slopes are not

required. Step 3: Existing

Surface

Step 3: Existing

Surface

The existing surface can be either a triangulation model or cross

sections of the existing road. To create a triangulation surface,

you need 3D data for the existing road (points and breaklines) and

then run Triangulate & Contour to create a .TIN file. To create

cross sections, use the routines in the Sections menu for

Input-Edit Section Alignment to set the section intervals and then

run one of the Create Section routines to make a .SCT file.

Step 4: Road Rehabilitation

Profile

Run this command and specify the 3 files created in steps 1-3. Also

set the output profile to create the .PRO file. On the second

dialog, choose the Milling method. Set the Milling Thickness to 3

inches. Set the Overlay Thickness to zero since the template

doesn't have a subgrade. Set the Template ID to EP to match the

grade from the template. Step 5:

Process Road Design

Step 5:

Process Road Design

Run this command and specify the 4 files created in steps 1-4. Also

set the output Design Section file to create a .SCT file for the

rehabilitation design.

Output:

The report

includes the total cut and cuts per station which is the quantity

of the milling.

Process Road Design

Template File> C:\sample\rehab.tpl

Profile File> C:\sample\rehab1.pro

Existing Surface File> C:\sample\road-ex.sct

Centerline File> C:\sample\simo2.cl

Design Section Output File> C:\sample\rehab1.sct

Processing 0+00.000 to 14+41.464

Total Cut : 9203.469 C.F., 340.869 C.Y.

Total Fill: 0.000 C.F., 0.000 C.Y.

Use Input-Edit Section File or Draw Section File to view the design

and existing sections.

Example 2: Milling with Overlay

Example 2: Milling with Overlay

This example adds an overlay thickness to the design from example

1. The steps are the same except for the following:

Repeat Step 2: Design

Template

Add a subgrade below the EP grade with a depth of 6

inches. Repeat Step 4: Road Rehabilitation

Profile

Repeat Step 4: Road Rehabilitation

Profile

Use the same settings as example 1 except set the

Overlay Thickness to 6 inches.

Repeat Step 5: Process Road

Design

Run this command again with the updated Template

and Profile.

Output:

The report includes the updated milling cut

quantities along with the overlay subgrade volumes. Since the

Milling Thickness stayed at 3 inches, the cut quantities stayed the

same as example 1. The Overlay Thickness being thicker at 6 inches

leads to more subgrade quantities and raises the new road above the

existing in areas.

Process Road Design

Template File> C:\sample\rehab.tpl

Profile File> C:\sample\rehab1.pro

Existing Surface File> C:\sample\road-ex.sct

Centerline File> C:\sample\simo2.cl

Design Section Output File> C:\sample\rehab1.sct

Processing 0+00.000 to 14+41.464

Total Cut : 9203.673 C.F., 340.877 C.Y.

Total Fill: 0.172 C.F., 0.006 C.Y.

Total Subgrade1 - Asphalt: 17295.031 C.F., 640.557 C.Y., 34592.253 S.F., 3843.584 S.Y.

Example 3: Leveling

Example 3: Leveling

This example applies leveling to an existing road. The steps are

the same as example 1 except for the following:

Repeat Step 4: Road Rehabilitation

Profile

On the first dialog, use the same data files as

example 1. On the second dialog, choose the Leveling method. Set

the Leveling Thickness to 3 inches. Set the Overlay Thickness to

zero since the template doesn't have a subgrade. Set the Template

ID to EP to match the grade from the template.

Repeat Step 5:

Process Road Design

Repeat Step 5:

Process Road Design

Run this command with the same

settings as example 1. The only difference is that the profile is

set for leveling instead of milling.

Output:

The report includes the total fill and fills per

station which is the quantity of the leveling.

Process Road Design

Template File> C:\sample\rehab.tpl

Profile File> C:\sample\rehab1.pro

Existing Surface File> C:\sample\road-ex.sct

Centerline File> C:\sample\simo2.cl

Design Section Output File> C:\sample\rehab1.sct

Processing 0+00.000 to 14+41.464

Total Cut : 0.000 C.F., 0.000 C.Y.

Total Fill: 8994.509 C.F., 333.130 C.Y.

Example 4: Leveling with

Overlay

Example 4: Leveling with

Overlay

This example adds an overlay thickness with a minimum of 4 inches

to the design from example 3. Part of the overlay will be in the

subgrade of the template and the rest will be in the Min Leveling

Thickness setting. The steps are the same as example 3 except for

the following:

Repeat Step 2: Design

Template

Add a subgrade below the EP grade with a depth of 2

inches. Repeat Step 4: Road Rehabilitation

Profile

Repeat Step 4: Road Rehabilitation

Profile

Use the same settings as example 3 except set the

Overlay Thickness to 2 inches and set the Min Leveling Thickness to

2 inches.

Repeat Step 5: Process Road

Design

Run this command again with the updated Template

and Profile.

Output:

The report includes the updated leveling fill

quantities along with the overlay subgrade volumes.

Process Road Design

Template File> C:\sample\rehab.tpl

Profile File> C:\sample\rehab1.pro

Existing Surface File> C:\sample\road-ex.sct

Centerline File> C:\sample\simo2.cl

Design Section Output File> C:\sample\rehab1.sct

Processing 0+00.000 to 14+41.464

Total Cut : 0.000 C.F., 0.000 C.Y.

Total Fill: 3228.086 C.F., 119.559 C.Y.

Total Subgrade1 - Asphalt: 5765.356 C.F., 213.532 C.Y., 34592.253 S.F., 3843.584 S.Y.

Example 5: Leveling with Overlay and Match

Slopes

Example 5: Leveling with Overlay and Match

Slopes

This example modifies example 4 to have the new road cross slopes

match the existing cross slopes instead of being at a fixed design

of -2%. The steps are the same as example 4 expect for the

following:

Step 2: Define Template

There are several methods to modify the template for transitions.

For this example, the Template Grade Table command is used. This

command defines slope and distance transitions for template grades.

In this example, we will only use the slope transitions to make the

design slopes match the existing road.

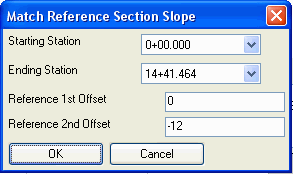

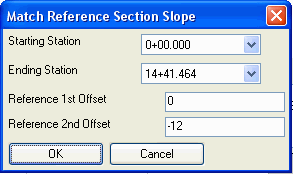

Run the Template Grade Table command and create a new .TGT file.

Select the rehab template that was used in example 4 as the

template to process. In the dialog, highlight the EP grade from the

list for the Left Surface. Then pick the Match Slope button. Select

the section file for the existing road. Next there is a dialog to

set the range of stations to process and the reference offset

points which are used to sample the existing surface to get the

slope between these offsets. In this example, the full station

range is used and the offsets are 0 for the center and -12 for the

left EP. Next, highlight the EP grade

from the list for the Right Surface. Then pick Match Slope and

select the existing section file. For the offsets, use 0 and

12.

Next, highlight the EP grade

from the list for the Right Surface. Then pick Match Slope and

select the existing section file. For the offsets, use 0 and

12. Then back on the main dialog, pick

the Save button.

Then back on the main dialog, pick

the Save button.

Repeat Step 4: Road Rehabilitation

Profile

Use the same settings as example 4 except set the

Template Grade Table on the first dialog.

Repeat Step 5: Process Road

Design

Run this command again with the updated Template

and Profile.

Output:

The report includes the leveling fill quantities

along with the overlay subgrade volumes.

Process Road Design

Template File> C:\sample\rehab.tpl

Profile File> C:\sample\rehab1.pro

Existing Surface File> C:\sample\road-ex.sct

Centerline File> C:\sample\simo2.cl

Template Grade Table File> C:\sample\simo2.tgt

Design Section Output File> C:\sample\rehab1.sct

Processing 0+00.000 to 14+41.464

Total Cut : 0.000 C.F., 0.000 C.Y.

Total Fill: 5765.382 C.F., 213.533 C.Y.

Total Left Subgrade1 - Asphalt: 2882.684 C.F., 106.766 C.Y., 17296.127 S.F., 1921.792 S.Y.

Total Right Subgrade1 - Asphalt: 2882.681 C.F., 106.766 C.Y., 17296.127 S.F., 1921.792 S.Y.

Example 6: Leveling with Overlay and SuperElevation

plus Lane Widening

Example 6: Leveling with Overlay and SuperElevation

plus Lane Widening

In this variation, the new road has both overlay and new design

changes of applying new superelevation and widening a lane. The

steps that are different than example 4 are described

here.

Step 2: Define Template

For this example, the template has additional design elements

besides the overlay grades. Run the Design Template command to add

the new elements.  First, pick the

Grades button to add a new grade for the new lane using a slope of

-2%, distance of 12 and ID of EP2. Then add a new grade for a

shoulder with slope of -4%, distance of 3 and ID of SH. Next,

subgrades are needed for the new lane since this isn't over the

existing road. Add a subgrade of 4 inches of asphalt under the new

lane and another subgrade of 8 inches of gravel. Next pick the Cut

button and set the cut slope to 2:1 and pick the Fill button and

set the fill to 2:1. The cut/fill slopes are needed to tie the new

road design elements to the existing surface.

First, pick the

Grades button to add a new grade for the new lane using a slope of

-2%, distance of 12 and ID of EP2. Then add a new grade for a

shoulder with slope of -4%, distance of 3 and ID of SH. Next,

subgrades are needed for the new lane since this isn't over the

existing road. Add a subgrade of 4 inches of asphalt under the new

lane and another subgrade of 8 inches of gravel. Next pick the Cut

button and set the cut slope to 2:1 and pick the Fill button and

set the fill to 2:1. The cut/fill slopes are needed to tie the new

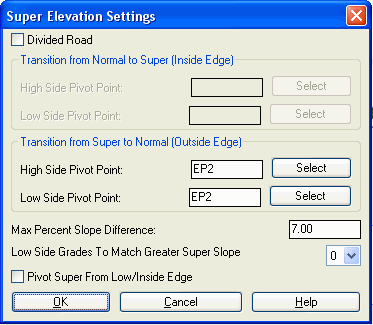

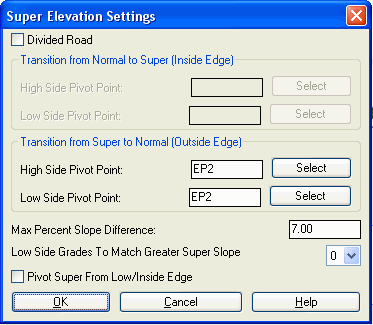

road design elements to the existing surface. Finally, pick the Super button to set the

superelevation transition ID's as EP2 so that the shoulder stays

outside the super. Then pick the Save button.

Finally, pick the Super button to set the

superelevation transition ID's as EP2 so that the shoulder stays

outside the super. Then pick the Save button. Even though

the template has the new lane EP2 defined for both sides, let's

actually only apply this new lane for a range of stations on the

left side. Run the Template Grade Table command and make a new .TGT

file. Select the template file that was just created. Then pick EP2

on the Right Surface list. In the table, fill in the first row with

station 0 and a distance of 0. This will eliminate EP2 on the right

side. Then pick on EP2 from the Left Surface list. Fill out the

table as shown to make the new lane start at station 3+00, reach

full size at 3+36, start transitioning back at station 9+00 and

return to zero at station 9+36.

Even though

the template has the new lane EP2 defined for both sides, let's

actually only apply this new lane for a range of stations on the

left side. Run the Template Grade Table command and make a new .TGT

file. Select the template file that was just created. Then pick EP2

on the Right Surface list. In the table, fill in the first row with

station 0 and a distance of 0. This will eliminate EP2 on the right

side. Then pick on EP2 from the Left Surface list. Fill out the

table as shown to make the new lane start at station 3+00, reach

full size at 3+36, start transitioning back at station 9+00 and

return to zero at station 9+36. Another

template transition definition to create is the superelevation. Run

the Input-Edit Super Elevation command and create a new .SUP file.

Use the option to select a centerline and specify the speed table

to have the program set the transition stations. Or use the Add

function to manually enter the transition stations and full super

slope.

Another

template transition definition to create is the superelevation. Run

the Input-Edit Super Elevation command and create a new .SUP file.

Use the option to select a centerline and specify the speed table

to have the program set the transition stations. Or use the Add

function to manually enter the transition stations and full super

slope. Repeat Step 4: Road

Rehabilitation Profile

Repeat Step 4: Road

Rehabilitation Profile

Use the same settings as example 4

except use the new template (TPL), template grade table (TGT) and

superelevation (SUP) created in step 2.

Repeat Step 5: Process Road

Design

Run this command again with the new template,

profile, template grade table and superelevation.

Output:

The report includes the leveling fill quantities

along with the overlay subgrade and the quantities for the new road

elements.

Process Road Design

Template File> C:\sample\rehab.tpl

Profile File> C:\sample\rehab1.pro

Existing Surface File> C:\sample\road-ex.sct

Centerline File> C:\sample\simo2.cl

Template Grade Table File> C:\sample\rehab.tgt

SuperElevation File> C:\sample\rehab.sup

Design Section Output File> C:\sample\rehab1.sct

Processing 0+00.000 to 14+41.464

Total Cut : 3549.129 C.F., 131.449 C.Y.

Total Fill: 22519.407 C.F., 834.052 C.Y.

Total Left Subgrade1 - Asphalt: 2882.699 C.F., 106.767 C.Y., 17296.127 S.F., 1921.792 S.Y.

Total Left Subgrade2 - Asphalt: 2399.867 C.F., 88.884 C.Y., 7200.000 S.F., 800.000 S.Y.

Total Left Subgrade3 - Gravel: 4799.622 C.F., 177.764 C.Y., 7200.000 S.F., 800.000 S.Y.

Total Right Subgrade1 - Asphalt: 2882.569 C.F., 106.762 C.Y., 17296.127 S.F., 1921.792 S.Y.

These sections show the road at a station before the new lane and superelevation and at a station with the new lane and superelevation.

Example 7: Leveling with Overlay with Lane Widening

at New Crown position

Example 7: Leveling with Overlay with Lane Widening

at New Crown position

In this variation, the existing road has two 10' lanes that are

being expanded to 12' lanes. The left EP is staying fixed and the

extra 4' is added to the right side. So the crown is shifting 2' to

the right. The steps are the same as example 4 except for the

changes to the template definition.

Step 2: Define Template

Use the Define Template command to make the template overlay and

widening grades. For this example, there is one 10' grade on the

left side for the overlay plus a 3' shoulder. On the right side,

there are four grades. The first right side grade is 2' for the

portion of the overlay that is shifting the crown over. The second

grade is 8' for the remainder of the right side overlay. The third

grade is 4' for the widening. The fourth grade is a 3' shoulder.

The template has subgrades of 2" for the overlay grades and has two

subgrades of 4" of asphalt and 8" of gravel for the widening grade.

Since this template is asymmetrical, uncheck the toggle for Right

Side Same As Left.

Next pick the Cut button and set the cut slope to 2:1 and pick the

Fill button and set the fill to 2:1. The cut/fill slopes are needed

to tie the new road design elements to the existing

surface. Repeat Step 4: Road

Rehabilitation Profile

Repeat Step 4: Road

Rehabilitation Profile

For the input files, use the

template created in step 2, the centerline and existing surface.

For the process options, choose the Leveling method and enter 2

inches for the Leveling and Overlay thicknesses. For the Template

IDs, specify both EP and EP2 since both of these are overlay

grades.

Repeat Step

5: Process Road Design

Repeat Step

5: Process Road Design

Run this command with the new

template and profile.

Output:

The report includes the leveling fill quantities

along with the overlay subgrade and the quantities for the new road

elements.

Process Road Design

Template File> C:\sample\rehab.tpl

Profile File> C:\sample\rehab1.pro

Existing Surface File> C:\sample\road-ex.sct

Centerline File> C:\sample\simo2.cl

Design Section Output File> C:\sample\rehab1.sct

Processing 0+00.000 to 14+41.464

Total Cut : 3462.106 C.F., 128.226 C.Y.

Total Fill: 8523.772 C.F., 315.695 C.Y.

Total Left Subgrade1 - Asphalt: 2402.152 C.F., 88.969 C.Y., 14413.199 S.F., 1601.467 S.Y.

Total Right Subgrade1 - Asphalt: 479.988 C.F., 17.777 C.Y., 2881.487 S.F., 320.165 S.Y.

Total Right Subgrade2 - Asphalt: 1921.865 C.F., 71.180 C.Y., 11531.712 S.F., 1281.301 S.Y.

Total Right Subgrade3 - Asphalt: 1921.510 C.F., 71.167 C.Y., 5765.856 S.F., 640.651 S.Y.

Total Right Subgrade4 - Gravel: 3842.962 C.F., 142.332 C.Y., 5765.856 S.F., 640.651 S.Y.

Pulldown Menu Location: Roads

Keyboard Command: rdrehab

Prerequisites: Centerline, template and surface

files

The first dialog specifies the road design files. All

these settings are the same as in Process Road Design except for

the Output Rehab Profile. This profile is the output result for

this command. The difference with Process Road Design is that the

profile is an output instead of an input. Please see the Process

Road Design section of the manual for a description of the other

input files.

The first dialog specifies the road design files. All

these settings are the same as in Process Road Design except for

the Output Rehab Profile. This profile is the output result for

this command. The difference with Process Road Design is that the

profile is an output instead of an input. Please see the Process

Road Design section of the manual for a description of the other

input files. The second dialog has processing options. Again, many

of these parameters are the same as Process Road Design. The

settings specific to this command are the following:

The second dialog has processing options. Again, many

of these parameters are the same as Process Road Design. The

settings specific to this command are the following:

Example 2: Milling with Overlay

Example 2: Milling with Overlay

Example 4: Leveling with

Overlay

Example 4: Leveling with

Overlay

Example 5: Leveling with Overlay and Match

Slopes

Example 5: Leveling with Overlay and Match

Slopes Next, highlight the EP grade

from the list for the Right Surface. Then pick Match Slope and

select the existing section file. For the offsets, use 0 and

12.

Next, highlight the EP grade

from the list for the Right Surface. Then pick Match Slope and

select the existing section file. For the offsets, use 0 and

12. Then back on the main dialog, pick

the Save button.

Then back on the main dialog, pick

the Save button. Example 6: Leveling with Overlay and SuperElevation

plus Lane Widening

Example 6: Leveling with Overlay and SuperElevation

plus Lane Widening First, pick the

Grades button to add a new grade for the new lane using a slope of

-2%, distance of 12 and ID of EP2. Then add a new grade for a

shoulder with slope of -4%, distance of 3 and ID of SH. Next,

subgrades are needed for the new lane since this isn't over the

existing road. Add a subgrade of 4 inches of asphalt under the new

lane and another subgrade of 8 inches of gravel. Next pick the Cut

button and set the cut slope to 2:1 and pick the Fill button and

set the fill to 2:1. The cut/fill slopes are needed to tie the new

road design elements to the existing surface.

First, pick the

Grades button to add a new grade for the new lane using a slope of

-2%, distance of 12 and ID of EP2. Then add a new grade for a

shoulder with slope of -4%, distance of 3 and ID of SH. Next,

subgrades are needed for the new lane since this isn't over the

existing road. Add a subgrade of 4 inches of asphalt under the new

lane and another subgrade of 8 inches of gravel. Next pick the Cut

button and set the cut slope to 2:1 and pick the Fill button and

set the fill to 2:1. The cut/fill slopes are needed to tie the new

road design elements to the existing surface. Finally, pick the Super button to set the

superelevation transition ID's as EP2 so that the shoulder stays

outside the super. Then pick the Save button.

Finally, pick the Super button to set the

superelevation transition ID's as EP2 so that the shoulder stays

outside the super. Then pick the Save button. Even though

the template has the new lane EP2 defined for both sides, let's

actually only apply this new lane for a range of stations on the

left side. Run the Template Grade Table command and make a new .TGT

file. Select the template file that was just created. Then pick EP2

on the Right Surface list. In the table, fill in the first row with

station 0 and a distance of 0. This will eliminate EP2 on the right

side. Then pick on EP2 from the Left Surface list. Fill out the

table as shown to make the new lane start at station 3+00, reach

full size at 3+36, start transitioning back at station 9+00 and

return to zero at station 9+36.

Even though

the template has the new lane EP2 defined for both sides, let's

actually only apply this new lane for a range of stations on the

left side. Run the Template Grade Table command and make a new .TGT

file. Select the template file that was just created. Then pick EP2

on the Right Surface list. In the table, fill in the first row with

station 0 and a distance of 0. This will eliminate EP2 on the right

side. Then pick on EP2 from the Left Surface list. Fill out the

table as shown to make the new lane start at station 3+00, reach

full size at 3+36, start transitioning back at station 9+00 and

return to zero at station 9+36. Another

template transition definition to create is the superelevation. Run

the Input-Edit Super Elevation command and create a new .SUP file.

Use the option to select a centerline and specify the speed table

to have the program set the transition stations. Or use the Add

function to manually enter the transition stations and full super

slope.

Another

template transition definition to create is the superelevation. Run

the Input-Edit Super Elevation command and create a new .SUP file.

Use the option to select a centerline and specify the speed table

to have the program set the transition stations. Or use the Add

function to manually enter the transition stations and full super

slope.

Example 7: Leveling with Overlay with Lane Widening

at New Crown position

Example 7: Leveling with Overlay with Lane Widening

at New Crown position