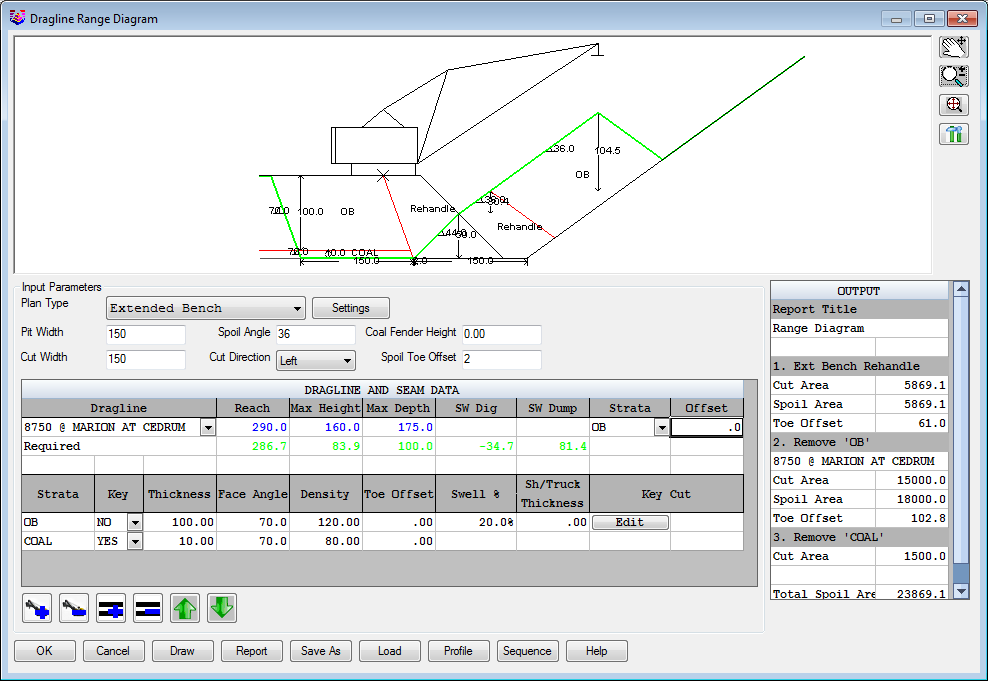

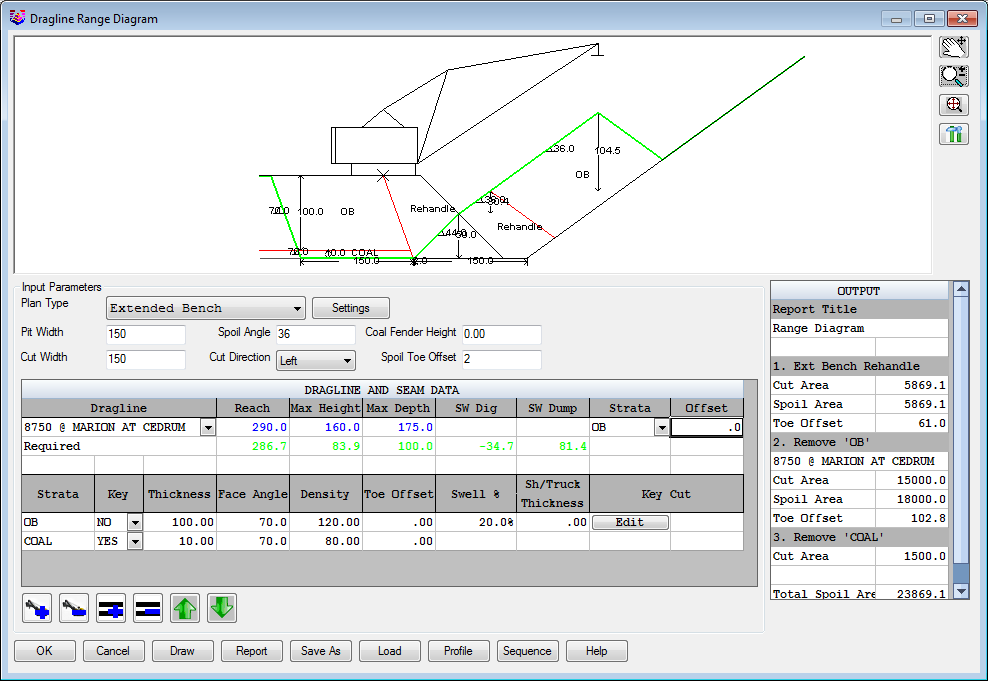

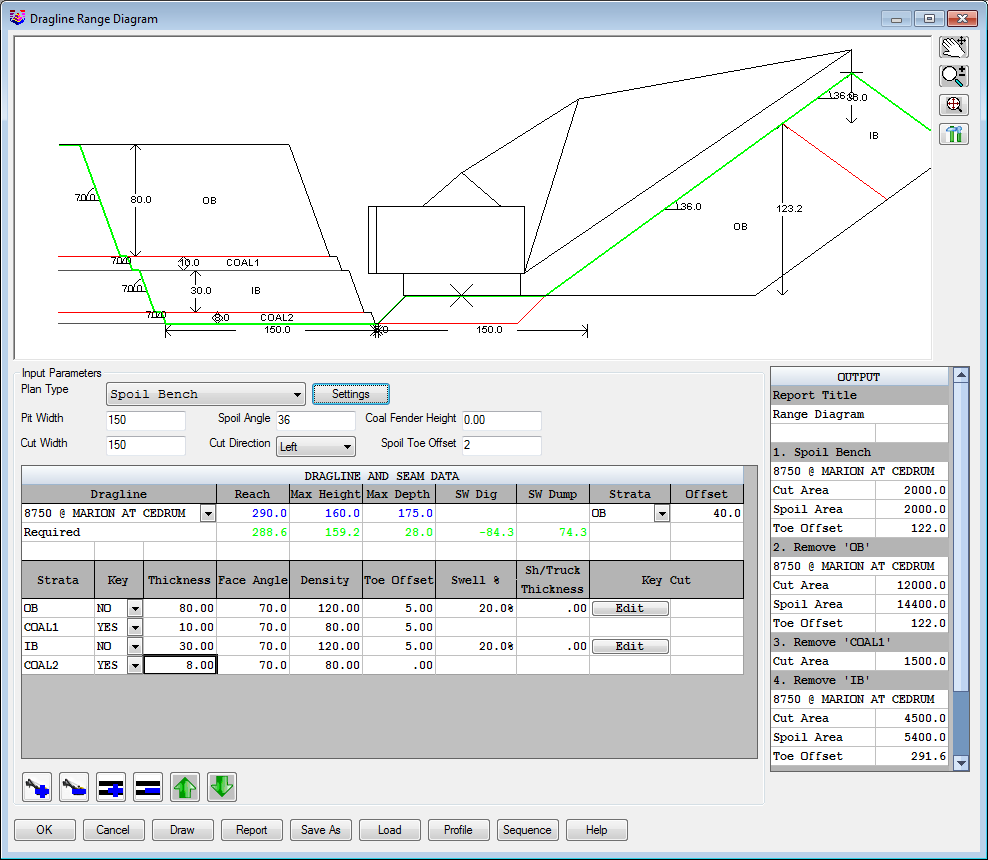

Range Diagram

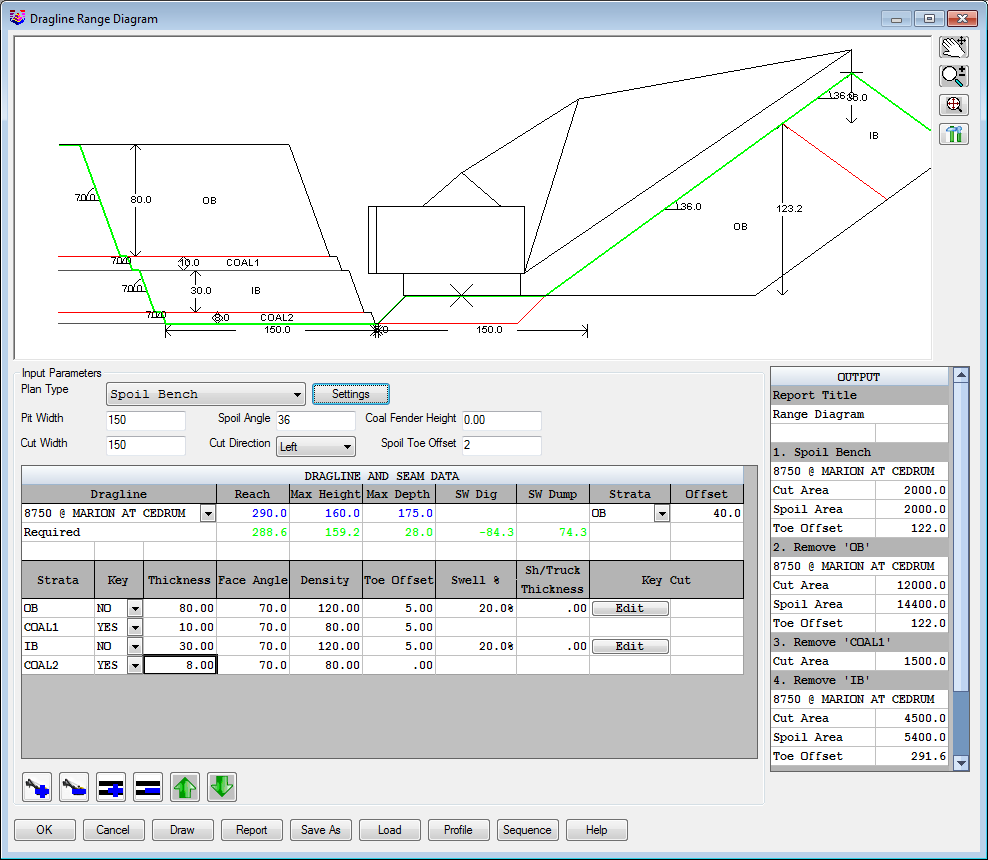

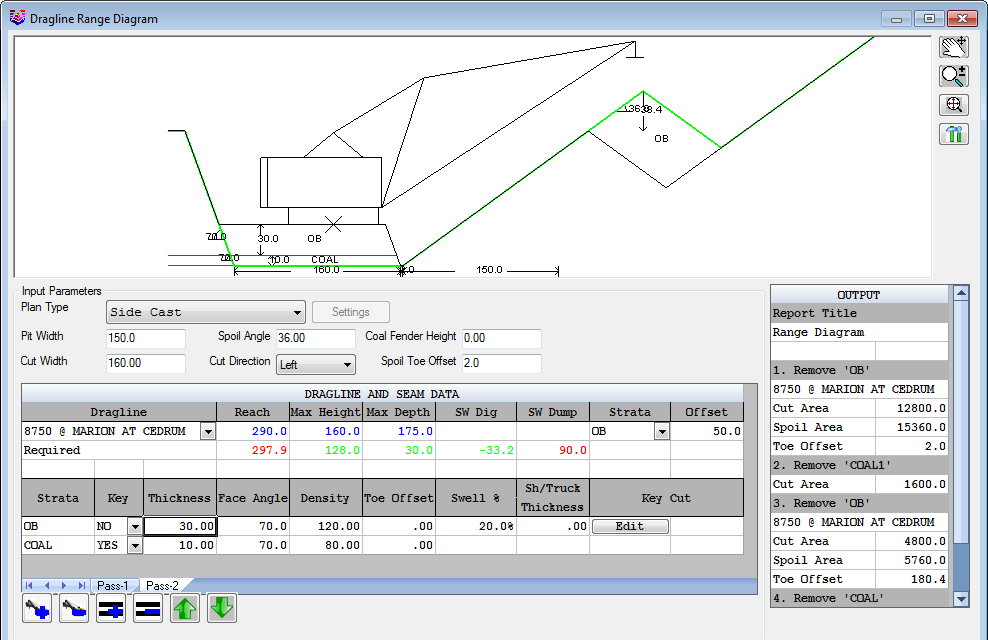

The Range Diagram command is an interactive tool that displays

graphics which are dynamically updated when adding or editing

values in the spreadsheet text below. This is a quick and easy way

to find parameters such as pit width, or to size a dragline to fit

the mining. Methods of mining include Side Cast, Dozer Push,

Extended Bench and Spoil side mining. Output includes both drawing

the sections in CAD and printing out reports as PDF files, where

each step is a separate page. A PRO profile and a SEQ sequence file

can be written from the final surface. Each option is detailed

below.

Input Parameters

- Plan Type: Selects

the mining method from Side Cast, Dozer Bench, Extended Bench and

Spoil Side.

- Pit Width: Sets the width of the existing, open pit.

This could be the previous pass, or a boxcut.

- Spoil Angle: Sets the angle of repose of the spoil

pile.

- Coal Fender Height: This option sets the height that is

allowed to cover the remaining coal with spoil, this leaves a wedge

of coal known as a fender.

- Cut Width: This parameter is the width of the new cut.

This is the field that is frequently changed to see what pit widths

will work

- Cut Direction: This

determines whether the cut is advancing to the right or left in the

graphics window. It is just a mirror image of either.

- Spoil Toe Offset: This setting places the toe of the

spoil this distance from the bottom of the coal seam.

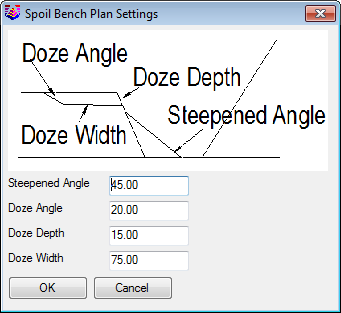

- Settings: This button option has three variations for

three different digging plan types. Each one is shown and mentioned

here.

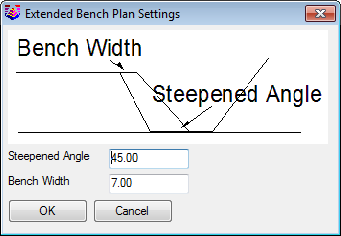

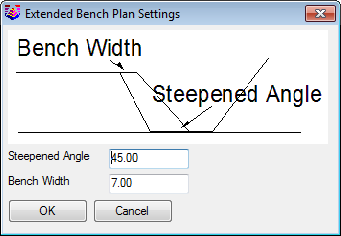

Extended Bench Plan Type and Settings. This option has

two settings to set the Steepened Angle of repose for the pushed

material, and to set the width that the bench is extended

horizontally.This method moves the bench out into the pit, and

displays the rehandled material both in the bench and in the

spoil.

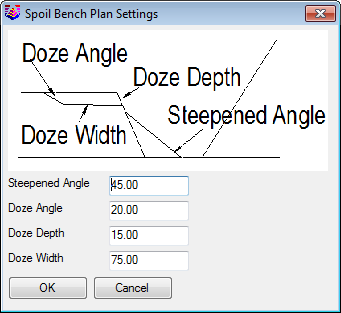

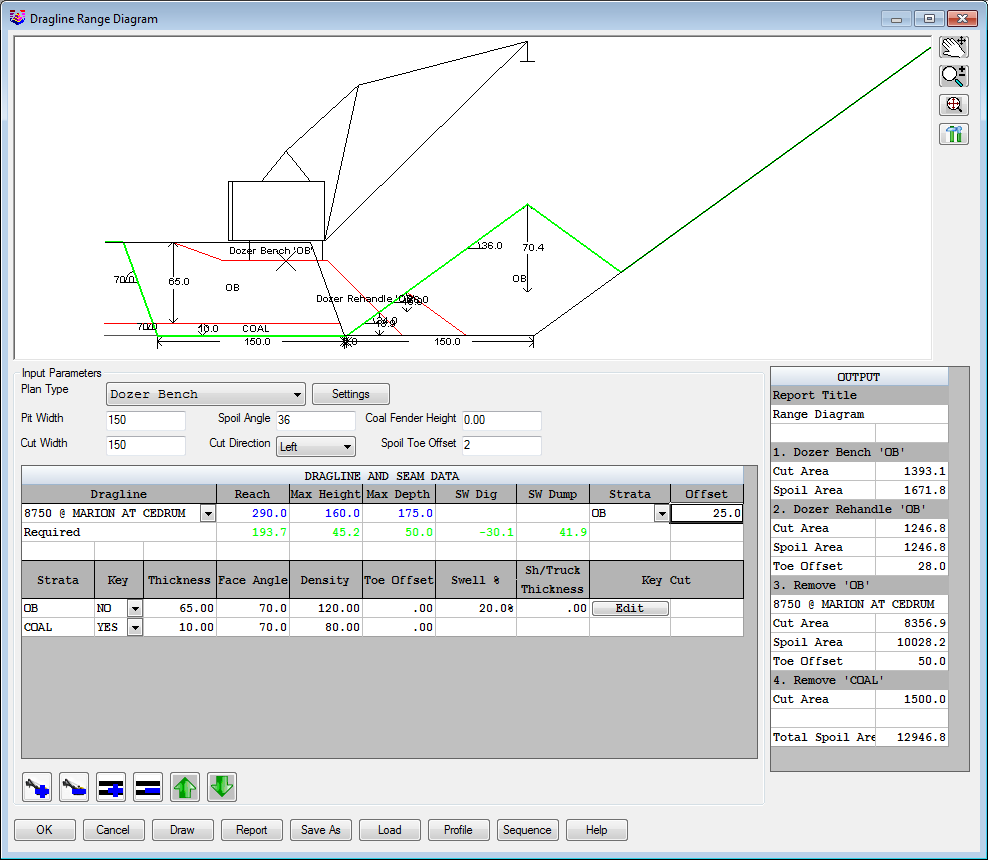

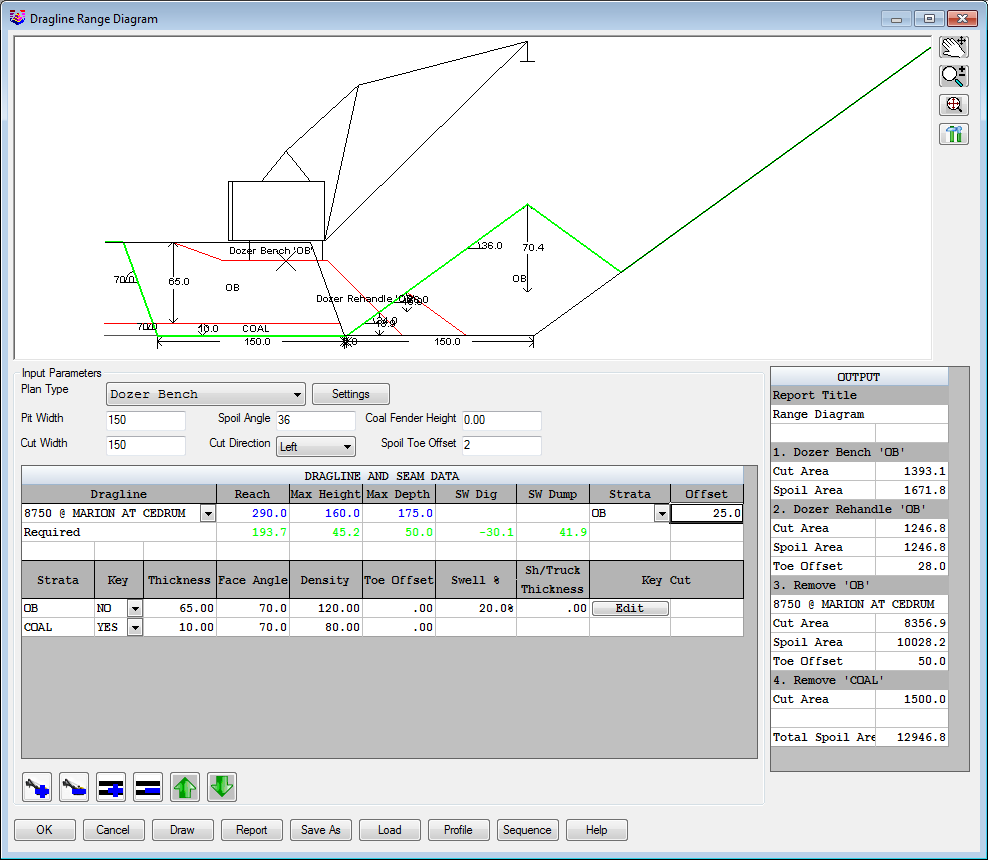

Dozer Bench Plan and Settings. These four settings control

the operation of dozer push. The Steepened Angle is the angle of

repose of the pushed material. The Doze Angle is the slope to push

down to the bench level. The Doze Depth sets how far down to push

from the top. And finally, the Doze Width sets the bench width of

the flat dozer bench. An example design of a dozer prepared bench

is below.

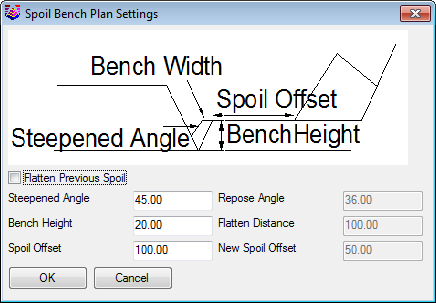

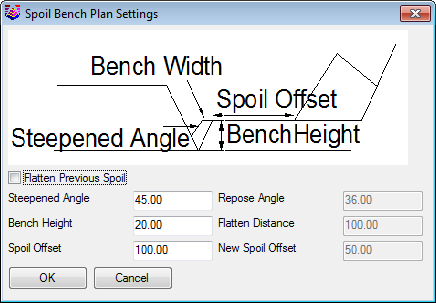

Spoil Side Bench Plan and Settings. These settings control

the spoil side bench dimensions. The Steepened Angle sets the angle

of repose of the bench material. The Bench Height sets the height

of the bench from the pit floor. The Spoil Offset sets the width of

the bench horizontally from the spoil. If the Flatten Previous

Spoil is turned on, then the Repose Angle Flatten Distance and New

Spoil Offset are active and will place the new spoil based on them.

For this option, there must be a previous spoil from an earlier

pass to flatten.

Dragline and Seam

Data

- Dragline: This dropdown

displays a list of predefined draglines. These can be added and

edited with the separate command Define Dragline

Equipment.

- Reach: This displays the

horizontal reach of the selected dragline. None of the colored text

can be edited. Since it is colored blue, it cannot be edited

here.

- Max Height: This displays

the vertical dumping height of the selected dragline. Since it is

colored blue, it cannot be edited here.

- Max Depth: This displays the

vertical digging depth of the selected dragline. Since it is

colored blue, it cannot be edited here.

- SW Dig: This reports the

dragline Swing Angle on the dig side. If it is red, then it cannot

reach the entire cut, even with a 90 degree swing.

- SW Dump:

This reports the dragline Swing Angle on

the dump

side. If it is red, then it

cannot reach far

enough to dump, and not cover the coal, even with a 90 degree swing. If it is green,

then that is the angle it needs to swing to dump and clear the coal,

or the fender height.

- Strata: This option sets the seam

that the dragline is sitting on. To represent a chop/dig setup

where the dragline sits on the second IB, while digging the OB, use

the setting as shown here. Otherwise it normally would sit on the

first OB.

- Offset: This sets the

distance for the dragline center pin offset from the crest of the

highwall. This applies to all four methods.

- Strata Row: This is the list

of strata added to the cross section.

- Key: The Key setting

controls whether it is waste (NO), and coal (YES).

- Thickness: This is where the

thickness of each strata or bench is entered. The section will

update graphically when a new value is entered.

- Face Angle: This setting

controls the highwall angle of each strata. It will update

graphically with any change here.

- Density: This is the

density of the material used for calculating tons.

- Toe Offset: This

option is used for placing the toe of the spoil a certain distance

from the toe of the highwall of coal or overburden.

- Swell%: This is the swell

factor of the material as it is moved from in-place to the

spoil.

- Sh/Truck Thickness: This

option controls whether any of the material is hauled away and not

spoiled. This is entered in as a depth from the top. This material

is removed and not placed in the spoil pile.

- Key Cut: The Key cut gives

the option to split the overburden block into two sections. The

first option is to turn it on with Use Key Cut. The Cut Side is

either Left or Right. This allows for moving the dragline to get

more spoil distance.

Left Key Cut

- Cut Width: The width is

entered in to set the horizontal distance of the bottom of the Key

cut.

- Cut Angle (degree): This is

the angle of the key cut highwall.

- Dragline Offset: This is the

distance for the dragline center-pin from the crest of the

highwall. This moves the dragline from the initial position to get

the Key cut moved.

- Add to Spoil: This option

determines whether to spoil or not. If it is hauled away by other

equipment, then this should be off. If it is spoiled with the

dragline, then it should be on.

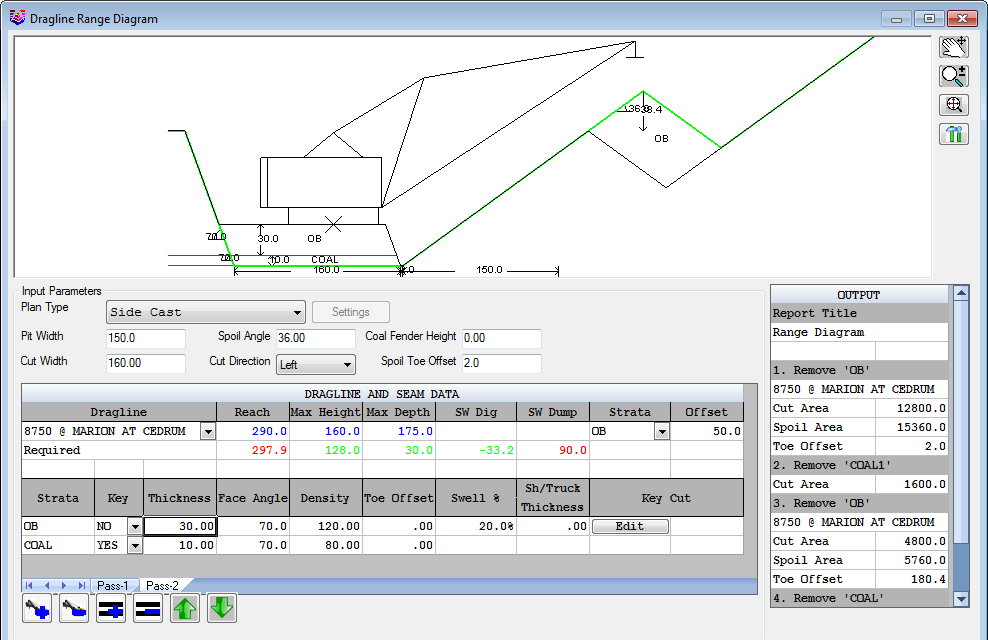

- Add Pass (+): This option places the dragline on another

strata. It can be the same dragline on another pass, or it can be

another dragline if there are more than one working in that

pit. Additional Draglines

or passes show up as different tabs below the spreadsheet. Shown

here is the same dragline as dragline1, working on a lower seam on

another pass, deeper in the pit.

- Remove Pass (-): This takes away the dragline tab that was

added to the diagram.

- Add Strata (+): Use this button to add each strata to the

diagram, such as OB, Coal or interburden. Once it is added, then

pick in the cell to give it the proper name and set its thickness,

angle and density.

- Remove Strata (-): This takes away the strata that was added to

the diagram.

- Move Up or Down Arrows:

This moves the selected strata up or down in the section.

Graphics Window: The ground surface is color

green.

- Pan: Pans around in the window

- Zoom: Zooms in and out in the

window

- Zoom Extents: Zooms the diagram to fit the entire display

window.

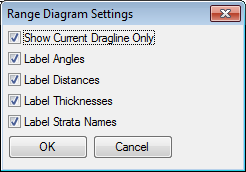

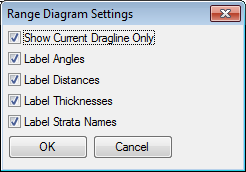

- Settings: This button

brings up the following dialog for settings:

- Show Current Dragline

Only: This should be on to see the dragline locations with a

Key Cut, and also to see the other dragline locations on other

passes.

- Label: These options

will label the angles, distances, thicknesses and strata names in

the display window.

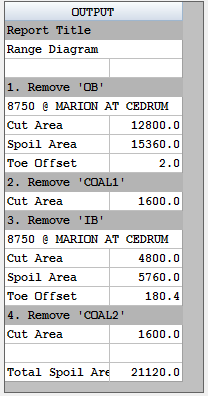

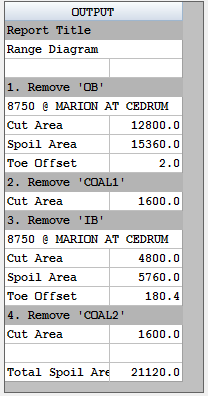

Output: The output shows up

in the lower right. It displays the area of the cut and fill of all

the material moved, and the dragline that moves it.

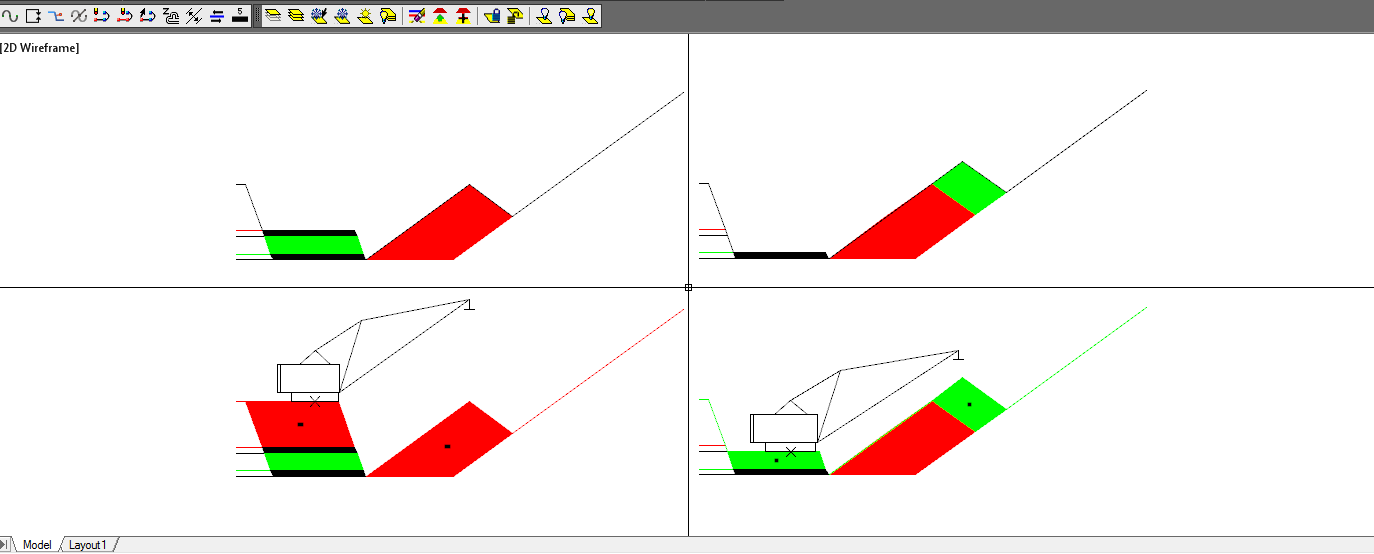

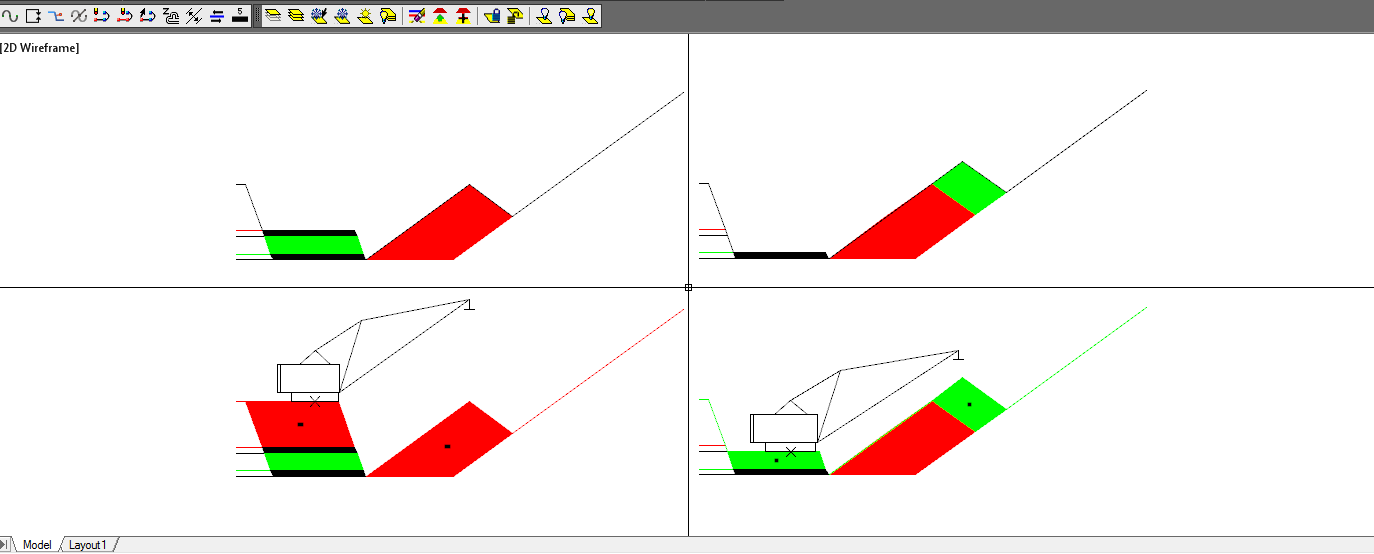

Draw: This option will draw

the steps in CAD as polylines with fill. It will prompt for the

starting point in CAD to draw them. Exit the command to see them in

CAD. Here is an example of what it draws, their colors and

entities.

Report: The report button will create a multipage PDF

document where each step in the section will be on a separate page.

Then at the end, one final page will show all the steps together

with the finished section.

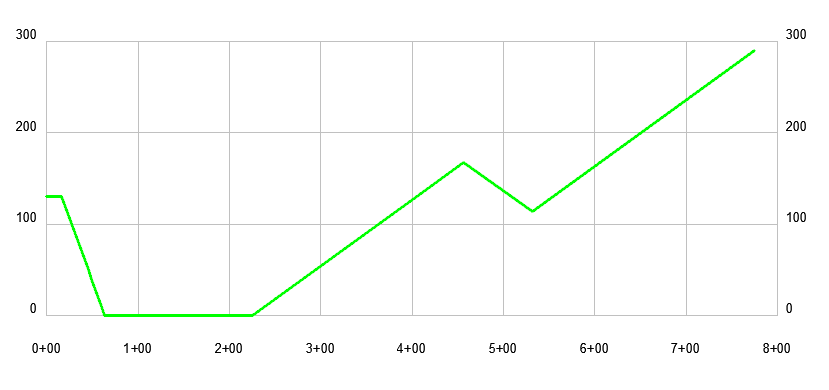

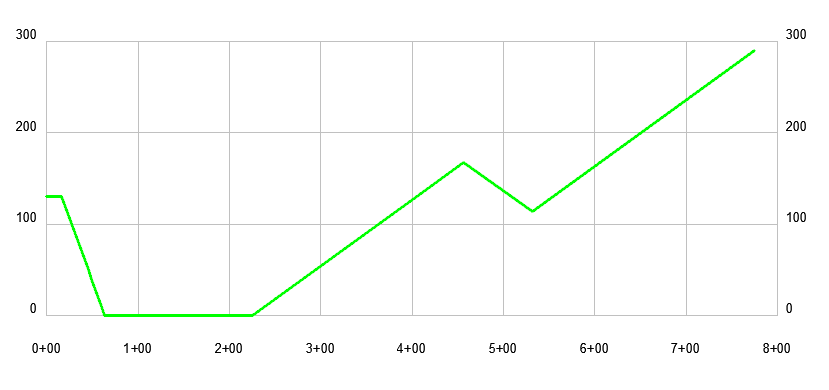

Profile: This option will

write out a PRO profile file for plotting and drawing with the

Civil or Survey module. An example is shown here from Draw

Profile.

Sequence: The SEQ sequence

file can be written and used in the Process Dragline Sequence

command. The centerline reference point where it will tie to a

centerline drawn in plan view is located at the toe of the highwall

and the bottom of the pit intersection.

Pulldown Menu Location: Surface

Keyboard Command: ranged

Prerequisite: dragline equipment defined