Surface Equipment Timing

Surface Equipment Timing schedules through surface pits and blocks

based on equipment mining rates in accordance with a calendar. The

mining rate is typically based on volume of overburden but may also

be based on tons of key strata. The calendar is set by the user to

indicate when entire days or individual shifts within a day are

down for holidays, time off, or other reasons. The pits themselves

must contain key strata and overburden information which is placed

in them through use of Surface Reserves, Import Timing Grids, or

Assign Timing Data. Surface Equipment Timing is distinct from

Surface Production Timing by requiring use of quantities or grids

stored in the pits, use of a calendar, and defined rates of

production for equipment. The Calendar, Equipment and Crews are

defined in the Surface Project Manager.

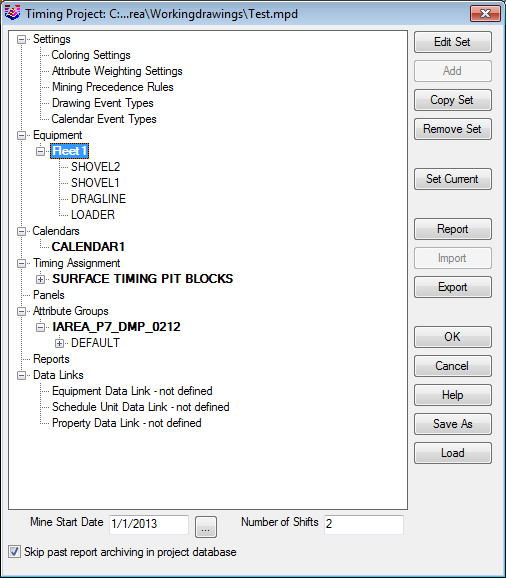

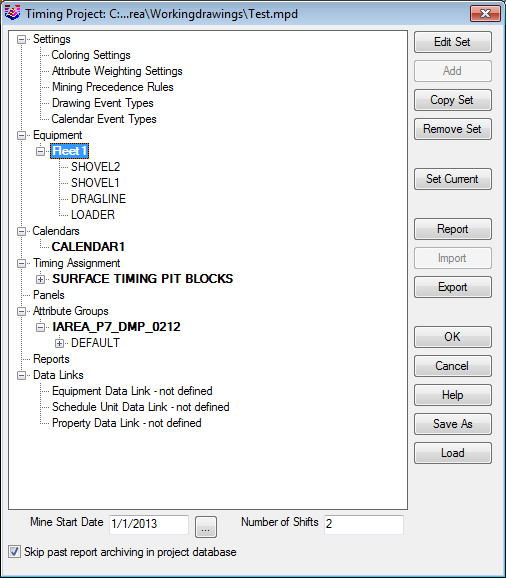

The Project Manager also appears at the start of Equipment

Timing. The purpose of the timing project database file is to

provide a single place where everything related to the timing

project is stored. This includes equipment definitions, reporting

settings, pit and panel information and reports produced. This also

includes other data such as calendars, equipment options, date and

weight tables, text block definitions. Basically everything except

for the grid files, which will be referenced. This means that

reviewing or even repeating results of a schedule done previously

will be much easier if everything including the last results is

stored in the same place.

The left side of the dialog has a tree control which displays the

categories of items on the top level, with either set of items or

actual items underneath. Depending on what is selected on the left,

the buttons on the right will reflect the functionality available

for the current selection. The sets of items showing in bold

reflect the current set when applicable: i.e. the project can have

multiple sets of equipment defined, but the one showing in bold is

one used in calculations. By double-clicking on the item the Edit

function can be executed if applicable. For equipment, the user can

edit, add, copy or remove entire sets of equipment. Use the Set

Current button to set a particular item current. Equipment can be

imported from an older Equipment Definition file or from another

project. It can also be exported to another file. A number of

different data can be output to an external data source or brought

up in the report formatter. Following is a detailed description

of each function on the Surface Timing window and subsequent

windows. After that is a step by step procedure for setting up for

the Surface Equipment Timing.

Following is a detailed description

of each function on the Surface Timing window and subsequent

windows. After that is a step by step procedure for setting up for

the Surface Equipment Timing.

- Add Unit: Selecting

this button will bring up a list of Available Equipment for

selecting a unit to add to the Surface Timing window. This must be

done first, before assigning pits or blocks.

- Edit Unit: This button

will go to the Equipment Production Rate window, similar to Define

Equipment. Any rate or shift changes made here will be saved to the

equipment file.

- Replace Unit: This replaces one unit with

another.

- Remove Unit: This button will remove the highlighted

equipment from the list of Equipment Involved. It will still

remain in the fleet for future use, just not on the list for the

current mine plan.

- Edit

Calendar: This will bring up the active calendar where any

changes and edits can take place.

- Do Earlier: This option will move a selected pit/bench

up the list in the Assignment window.

- Do Later: This option will move a selected pit/bench

down the list in the Assignment window.

- Remove: This option will move the selected pit/bench

from the Assignment window back to the Unassigned

window.

- Remove All: This option will move all of the

pits/benches from the Assignment window back to the Unassigned

window

- Add

Delay: This inserts a delay in-between the pit blocks. This

brings up the same delay setting as found in the Drawing

Events.

- Assign: This button will move the high lighted

pits/benches from the Unassigned window over to the Assignment

window.

- Select: This is to select the pits and their

appropriate benches for assigning. It will highlight them, ready

for the Assign. The choices to select are None, All, or by bench

number, such as all the Bench2, or the Bench3.

- Use

Precedence: This gives the ability to adjust sorting of

unassigned pits/panels so that precedence is satisfied (violating

names are moved down the list until precedence is

satisfied)

- Screen Pick: Selecting this allows for screen picking of

the pits in plan view. Cross-hairs appear, and the command line

states: Pick on or inside of pit polyline or Enter to finish:. Pick

inside the pits in the order they should be assigned. Picking once

assigns the first available bench. Picking again in the same pit,

assigns the next bench (if available) immediately after the first

one. Hit Enter to get back to the Surface Timing screen, and the

pits should be assigned in the order picked on

screen.

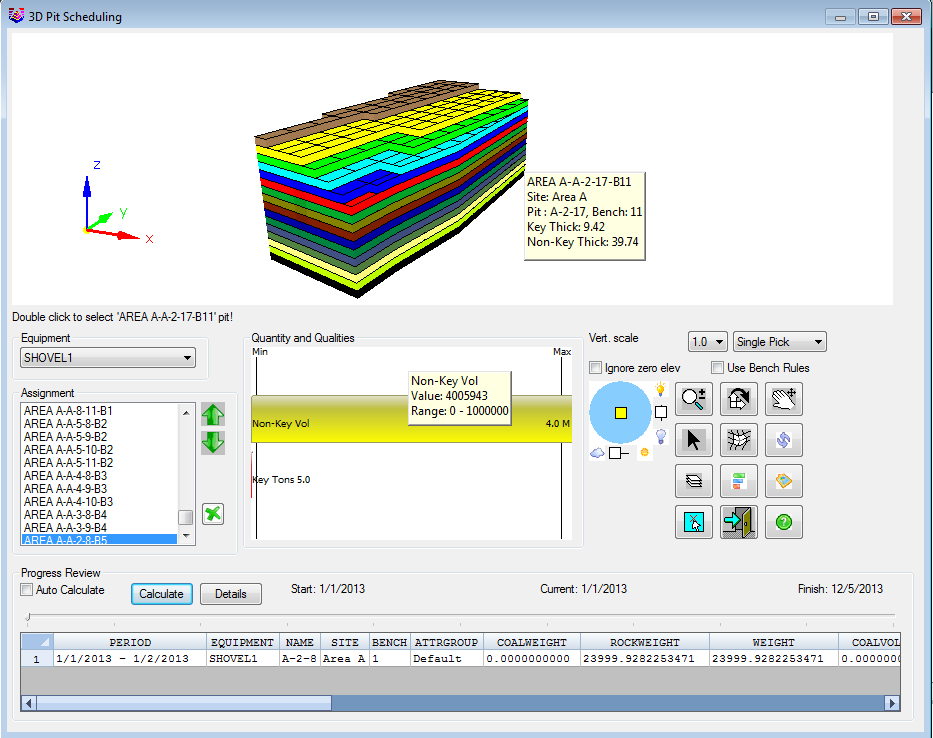

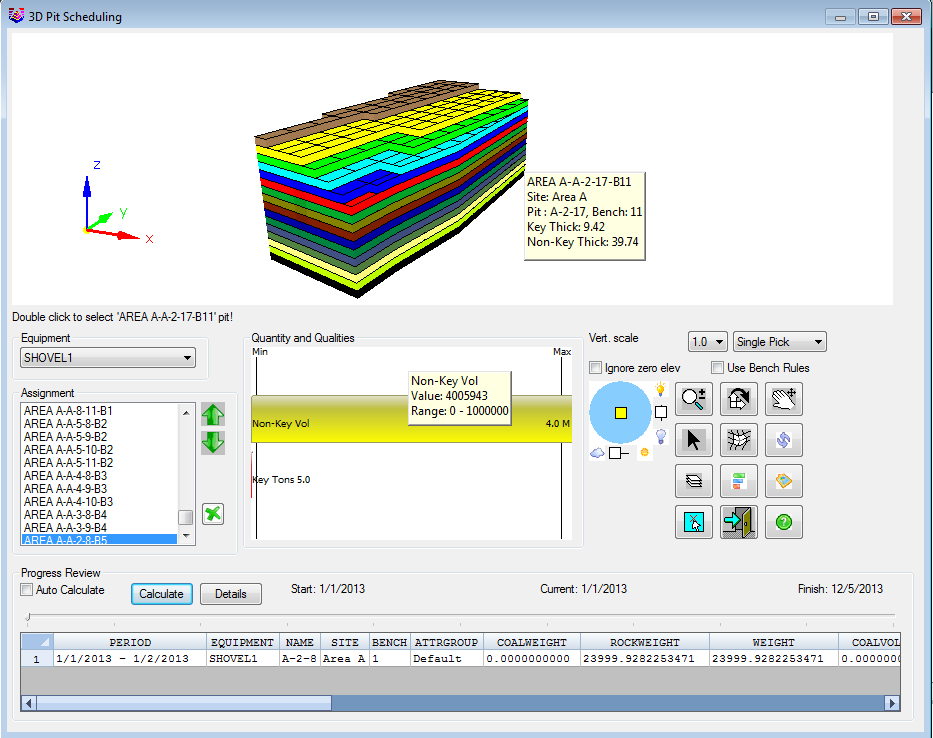

- 3D Pick: This option gives a 3D view of the pits and

the quantities stored in them. It allows for viewing, rotating and

selecting of the pits to be mined in 3D. When a pit and bench is

picked, it disappears from the mine plan, revealing the block

beneath it. There must be a Pit Attribute called SURFACE with the

surface topography grid assigned to it. Rotate the view to see the

benches in 3D, select a unit, and start picking the blocks in the

order to be mined. The “mode” it is in will determine what the

mouse icon is.

- Vertical Scale: This dropdown allows a

different vertical scale set in the window from 1X to 16X

- Single Pick / MultiPick. This allows for

switching between selecting one pit block at a time, or a range. To

select a single pit block, set the mouse to the arrow/pointer, then

double click on a pit block to remove and mine it. If there is a

range of pit blocks to select, choose the Multi Pick option and

using the same arrow pointer, double click on the starting pit

block, and then again on the ending pit block of the line of blocks

to mine. Keep picking until the end of the string is reached. It

will draw a red line from pick to pick. When finished, Right Click

the Mouse, and all the blocks crossed by the red line will mine out

in the order they were crossed. This will remove and mine that

entire range for scheduling.

- Use Bench Rules: This option will apply the

bench rules to benches on top and those are assigned to the

equipment selected for each bench in order top to bottom with

defined sequence. The Bench Sequencing screen to set this up is

shown below.

- Zoom button gives the magnifying glass with

the +/- to zoom in and out

- Rotate button gives the XY icon to tip it on

its side, and the Z icon rotates it around the Z axis

- Pan button gives the hand and pans around

the screen.

- The Pick arrow button is the easiest icon to

select the pits with. Just move the icon on top of a block and

double click with the left mouse button. The name of the pit and

bench it is pointing to is shown above the equipment window.

The block will disappear and the name will be added to the

Assignment list. Any mistakes can be removed with the Remove

Button, the green X.

- The Shade button renders the pit benches

otherwise they are just 3D faces not shaded.

- The Zoom Extents button returns to plan

view, and zoomed to the extents.

- Turn Benches On/Off button brings up the Set

Layers window where unselecting a specific bench will remove it

from the 3D image. Each bench color can be set here for better 3D

visualization. These color settings can be saved and loaded at a

different time. The Mining Rules sets up the precedence on what

must be mined in upper benches to get to the desired block below.

Bench Sequencing allows the user to setup default equipment for

each bench and bench sequencing rules with ability to play back the

sequence with the Play arrow >. A mining sequence rule for the

top bench can be setup for each bench by setting the offset in

North, East, West and South direction where North begins the twist

screen angle from the drawing. Use the Twist Screen command first

to rotate the blocks if they are not laid out on a N-S-E-W pattern.

Once the rule is setup for one bench it could be applied to all the

benches with the Set to All. The Upper Bench Offsets control how

many blocks must be removed in each direction from the bench above.

The Upper Bench Sequence sets the order of how to mine these

blocks.

Once the bench rules are setup, there is an option to select the

Bench to draw the advance on the screen by using “Draw” button,

this will draw the perimeter for each bench on top, to show how

much needs to advance to uncover the underlying bench for the

selected pit. The perimeters will be drawn with the selected color

for each bench in CAD.

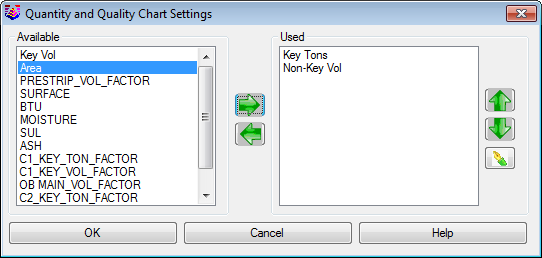

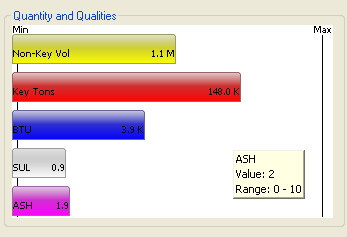

- The Chart Settings button brings up the

window for selecting the bar chart attributes to display.

Everything stored in the pit benches is available to display in the

bar charts. When a pit bench block is selected, the tons, volume or

quality of the bar charts increases to show the values. This shows

a running total of the values as each block is picked and removed

to be mined. The ranges for each attribute set the minimum and

maximum values for the bars on the chart. So, as an example if

200,000 tons are needed for some short range mine planning, set the

Key Tons to 200,000 maximum and then it is easy to see how many

blocks are needed to be picked to get to that volume. Or, if a

certain quality of Key material is needed, select blocks and

monitor the quality to keep it in the desired zone.

- Timing can be run from this window by

selecting the Report button. It brings up the window with the

finish date, where the Report or the Detailed Report are selected.

Choosing Detailed Report brings up the Report Options and runs the

schedule, and hatches the pit blocks in the drawing.

- The blue circle with the yellow square in it

is the light control, to cast shadows where the light shines from

the direction selected.

- The Vertical Scale box changes the scale for

better viewing of sites with low relief.

- Screen Entities button will allow for any

picking in CAD of 3D entities to show up in the 3D Pick window.

Entities such as contours, ramps, roads, pit shells and perimeters

can be selected and viewed with the blocks in the 3D Pick

window.

- When done, just hit the Exit button (the

door with the arrow going out) and you are back to the main Surface

Timing sequencer.

The program uses the SURFACE grid as a starting elevation and the

thickness of each block is relative to the volume of material

assigned to each bench in the pits. Benches with more volume will

show up thicker than others with less. The color scheme is based on

the bench you are on. For better viewing of complex

pits with separate bench polylines in 3D, surface attribute for

each bench can be defined with attribute name SURFACE_BENCH# and

value equal to the bench bottom elevation grid. If these attributes

are defined the program builds the 3d pick view from top-down

calculating the thickness on each pit vertex as elevation

difference between two consecutive benches. The red text indicates

the grids are moved and cannot be found at that path. There is a

reset folder button to address it.

- Add Delay of Days/Shifts:

Adding a number in the day or

shift window and hitting the Add Delay button will bring up the

following windows. Highlight the pit/bench in the Assignment window

and the delay will be added below the row that is

highlighted.

The

Schedule Effect on Delay gives two choices: Schedule delay, where

the delay will take affect when the equipment is working. If the

calendar has the equipment off at that time, then the program waits

until it starts to work again, then schedules the delay. A Calendar

delay, where if the calendar has it off already, then that is all

it will do. It will not take it off additionally. The Due To option

provides Drawing Event Types to choose from. Choose the button with

"..." next to the Due To, to open the Drawing Event Types window.

To Add or Edit a type, the Capture/Timing Event Definition screen

provides names and productivity options. Anywhere the text drawn in

the Capture Layer is encountered in the drawing, the equipment will

be delayed by the Event Delay Length in shifts. The Productivity

Effect is the result of the delay. Not working is where the

equipment is completely down. Working is no change, and Not

Producing is where the equipment is in use, but no quantities are

being mined.

- Assigning Bench Specific Events:

If you want an

event to associate with a specific bench put the event on the layer

with “_BENCH##” (## - Bench Number) suffix to layer name. For

example if the dragline move event occurs only on the bench 3 the

capture layer name would be “DraglineMove_BENCH3”, if there isn't

any _BENCH## it would apply to all the benches. Also update the

Capture Layer name in the event definitions to

“DraglineMove_Bench3”.This would make sure that drawing event will

occur only on the equipments working on Bench3. You can specify

other event on specific benches same way.

- Undo Report: This option will Undo a previous Surface

Timing run. It will delete the blocks or perimeters drawn in the

drawing. If a quick change to the plan or equipment is made, it can

be re-run very quickly just by hitting Undo Report and then

Calculate again.

- Starting Date: This must be filled in before selecting

Calculate. Use the format that is defined for dates in Configure

under Settings. It can be 12/15/2014 (month/day/year) or 15/12/2014

(day/month/year) etc.

- Number of Shifts: This is the number of shifts the program

will use in the actual sequencing. Even if 3 shifts are defined for

the equipment or in the calendar, and 2 is entered here; it will

only use 2 shifts in the timing. It uses the first two, ignoring

the third shift in the equipment rate and calendar.

- Skip Ore (Key Strata) for Timing:

This toggle will determine if

the equipment is mining just the NonKey/Overburden material or both

the NonKey and Key Material that appears in the pit and bench. For

example, a dragline moving overburden should have this checked so

that it ignores the coal volume. It will still report the Key

volume and tons, but not use it for the schedule.

- Perform Bottleneck Analysis /

Bottleneck Parameters: Bottleneck analysis is an option in Surface

Equipment Timing that lets you limit the total production from

several units to a specific level, even if the sum of the units’

production exceeds the set level. To use this method, check the box

for Perform Bottleneck Analysis and then set the

parameters.

The Bottleneck

Parameters dialog box is found on the Surface Timing dialog under

the Bottleneck Params button. The Field Name you specify must

match one of the reserved words for volume, tons, or a user-defined

attribute. These reserved names can be found in the Edit User

Attributes section in the final report if they are not known. The

Threshold value is another name for the limit placed on the

attribute name. This limitation can be set for specific

equipment units, and it can be set for ALL units as well. To

set the unit preference order, ADD them to the dialog box to the

right under the Equipment Order heading. The order can be

changed by highlighting the unit (by selecting it with the left

mouse button) and picking the UP or DOWN button to the right.

The Bottleneck

Parameters dialog box is found on the Surface Timing dialog under

the Bottleneck Params button. The Field Name you specify must

match one of the reserved words for volume, tons, or a user-defined

attribute. These reserved names can be found in the Edit User

Attributes section in the final report if they are not known. The

Threshold value is another name for the limit placed on the

attribute name. This limitation can be set for specific

equipment units, and it can be set for ALL units as well. To

set the unit preference order, ADD them to the dialog box to the

right under the Equipment Order heading. The order can be

changed by highlighting the unit (by selecting it with the left

mouse button) and picking the UP or DOWN button to the right.

There are several

schemes you can use to determine which units are restricted to meet

to required level.

When production capacity exceeds

the systems ability to absorb it some units need to be scaled

back. The options available to reduce production

include:

1.

Normal Rotation - alternates in

order through the units.

2.

Hold Lead, rotate rest – operates

the primary unit at full capacity and alternates through the rest

of the units reducing production.

3.

Hold tail, rotate rest -

opposite of Hold Lead.

4.

Fixed order – maintains the order

of unit preference reducing production, beginning with the tail

unit until it is completely down, then reducing the next in

preference order until the objective is met.

Example: There are 4

excavators on a job (Units A-D )with a capacity of 3,000 cyds per

shift. All of the material must be loaded in trucks and

hauled away. There are 6 trucks in the fleet with the ability

of hauling 1,000 cyds per shift. Therefore, the trucks in

this case are the bottleneck of 6,000 cy/shift, limiting production

of the excavators.

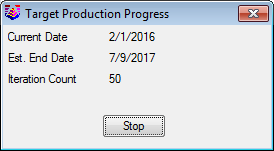

Using the

fixed order as the restriction scheme, we will limit the tail

unit’s production every shift that the excess excavator capacity

exists. When the schedule is run, it checks the shift

capacity for each shift as the program times out the

progress. This slows the program down, showing a bottleneck

window with the dates counting by, but keeps the production

capacity in line with the desired production level. A report

is generated showing which unit is reduced and by how much. An

example report is shown here.

Using the

fixed order as the restriction scheme, we will limit the tail

unit’s production every shift that the excess excavator capacity

exists. When the schedule is run, it checks the shift

capacity for each shift as the program times out the

progress. This slows the program down, showing a bottleneck

window with the dates counting by, but keeps the production

capacity in line with the desired production level. A report

is generated showing which unit is reduced and by how much. An

example report is shown here.

When the schedule

is run and the map is hatched showing the progress, note the

additional time periods for Units 3 and 4. This shows Units 3

& 4 have been held back while the other units worked at full

production. Unit 4 is not even working in some of the early months.

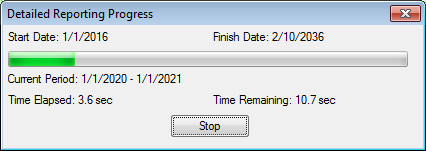

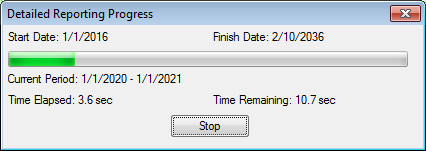

There is a progress bar to show the time elapsed and time remaining

for very large mineplans that take a while to run.

When the schedule

is run and the map is hatched showing the progress, note the

additional time periods for Units 3 and 4. This shows Units 3

& 4 have been held back while the other units worked at full

production. Unit 4 is not even working in some of the early months.

There is a progress bar to show the time elapsed and time remaining

for very large mineplans that take a while to run.

A report shows the amount added

by unit.

- Calculate: This is the button to start the sequencing.

Choosing this button will bring up a small window displaying the

completion date. Or if the bottleneck parameters are being used, it

will display the days counting down and the various Loops it is

using in the calculations. There are two report choices shown here.

The Report button will bring up the Equipment Report where the

following parameters, such as start and finish dates and the days

waiting or pit available are displayed. This is useful to determine

if there is a delay due to a unit holding something up. The

Detailed Report will go into the Report Options Screen described

next. This is the same as the Report button from the initial

screen.

- Report: Selecting this will go into the Report

Options screen. It should only be active if the Calculate button

has be selected previously. This is where many settings in the

schedule are set, such as the breakdown of the time periods,

hatching etc. The Report Options is defined next.

Report Options. Each item on the dialog box is defined

below.

- Report by period: This

option runs the schedule and breaks the pits into blocks by period,

such as month or year. The blocks and outlines are colored by

period and displayed in the report. The report can be formatted may

ways.

- Report by equipment:

This option runs the schedule and breaks the pits into blocks by

Equipment. The blocks and outlines are colored by equipment and

displayed in the report. The report can be formatted may

ways.

- Report Only: Choosing

this option will not draw any blocks or outlines on the map. It

will go directly to the Report Formatter for viewing of the

data.

- Draw blocks: When this

option is selected, the periods or equipment will be drawn as

blocks of solid fill or any AutoCAD hatch pattern that is

chosen.

- Draw distinct outline:

When this option is selected, the periods or equipment will be

drawn as closed polyline outlines.

- Draw legend: This

option draws a legend and the picked location on the map. The

colors are based on period, custom amounts or equipment.

- Pastel colors: Choosing

this option draws the blocks or outlines in the pastel color region

of the AutoCAD palette. It uses colors in the 11, 21, 31, 41 etc.

row. If it is not selected, then it will use the brighter, primary

colors such as 10, 20, 30, 40, etc. This is useful for plotting,

the colors are lighter and use less ink.

- Enforce custom colors:

Selecting this option will use the custom color palette the is

setup with the Custom Dates and Colors Table.

- Custom table:

Dates/Colors: This brings up the Define Ranges screen. This

is where a custom date or color table can be set up. The Auto set

button will bring up the smaller window for entering the starting

line (row number), starting date, how often to repeat, and how long

to keep repeating. The Set colors will prompt for a starting color,

and the color number increment. The colors are set by picking the

color box. The Pattern is the pattern of the hatch in the blocks.

The Scale is the size of the hatch patterns if a hatch is used. The

Layer is the AutoCAD Layer of the period. Finally, the Label is

what each period will be called for reporting and labeling.

The example shown here has created a weekly schedule with custom

colors. The Clear button wipes out the data for starting over. The

tables can be saved and loaded as CDT files. To use this option,

choose Enforce Custom Colors or Custom Date Table.

- Custom table: Amounts:

This button brings up the Define Levels window. This is where the

amount to target is set for the Custom Amounts option in the

report. The amount to target is set in the first column. The next

column is the color for the blocks and outlines. The colors are set

by picking the color box. The Pattern is the pattern of the hatch

in the blocks. The Scale is the size of the hatch patterns if a

hatch is used. The Layer is the AutoCAD Layer of the period.

Finally, the Label is what each period will be called for reporting

and labeling.

- Change shade color

every: This option will change the color/layer of each block

or outline. There are 3 choices. Every Period (what is selected

below), Year, or 5 Years.

- Block labeling: This

pull-down is for setting the labeling options. There are 5 options

here. No Block Labels will not draw any labels. Draw Actual Dates

will draw the date of each period. Draw Period Names will place the

period name in the block that is entered in the custom date table.

Use Custom Names draws the names entered in the custom amount

table. Use Custom Text Block activates the Add, Edit and Remove

buttons. Choosing Add or Edit will bring up the input screen for

arranging the text items in the block. First, give the new block a

name. Then move items from the left side to the right, in the row

desired. The Add Text button allows for custom text for prefix or

suffix entry. The Add Attribute adds any attributes that exist in

the schedule. Add New Line moves the added item to the next row. If

this is not selected, then the next item is added to the same row,

with a + as a separator. Remove will move the entire row from the

Line definitions.

- Text Size/Text

autosize: This will either place all text in the map with

the defined size, or autosize it to fit in the block

dimension.

- Length-wise

labels: This option draws the text parallel with the

long axis of the pits. If it is not selected, then the text will be

90 from the long axis.

- Text Style: Enter in an

AutoCAD text style for labels.

- Text Block Style: This

section is active if the Block labeling is set to Use Custom Text

Block. Any premade blocks will appear on the list and may be

selected for text orientation.

- Report Period: This is

the start and finish date of the report. By default, the program

will display the full range from the start date to the final date

it needs to finish. Any date range in the middle may be

used.

- Skip format prompt: If

this option is selected, then after the blocks are drawn, a report

will appear that is similar to the last one created. The program

will not bring up the report formatter for customizing.

- Sub-divide by

properties: If this is selected, the schedule will recognize

any named Carlson property lines drawn on the mineplan. In the

report, the periods can be further subdivided by property and

owner. These are the same property lines that are used in Surface

Mine Reserves.

- Output period grids:

Choosing this option will create a grid file of the 3D surface at

the end of each period, such as a month or a year. It needs the

Surface Grid and the Bottom of Pit Grid. It needs at least the

Bench 1 Grid filled in to make the grids. The Bench Grids will come

in automatically from the Pit Attributes, where the SURFACE

attribute is defined as the topography, and each benches bottom

elevation is defined as SURFACE_BENCH*. If they aren't define in

the Pit Attributes as such, then each grid will need to be selected

here. A new output grid path with an Output Grid Prefix is set to

create new grids of each period. A new grid file is then written of

each period for the pit and bench. This can be an "ultimate pit"

used in other design work. It doesn't have the flexibility of other

commands such as Design Bench Pit, but it gives a 3D surface of

each period mined. It uses a constant highwall slope of around 80

degrees, but varies based on the grid cell size.

- Period Polylines to

Pits: Selecting this option creates and names the outlines

as Carlson pits. The names of the pits are the actual period names.

This is useful if these period polylines need to be saved and

re-run in the Surface Mine Reserves for additional quantities or

analysis.

- Output Spoil File: This

option creates the SPO file that is used for the timing of the

spoil commands found in the Spoil menu. This output contains the

nonkey waste for spoil placement and timing.

- 12 months + 8 quarters +

years: A schedule run with this option will break down the

first year into 12 monthly periods, the next two years into 8, 3

month quarters, and the remaining periods will be full

years.

- Show Months of

Development: This method will use the starting day and

increment by month to the same day. For example, if the starting

day is on the 12th of each month, the schedule will be from the

12th to the 12th for each month.

- Show 1st Days of

Months: This method will use the starting day and increment

to the first of each month. For example, if the starting day is on

the 12th of the first month, it will go to the end of the first

month and then start fresh on the 1st of each month.

- Show Years of Development:

This method will use the

starting day and increment by year to the same day. For example, if

the starting day is on June 15th, the schedule will be from June

15th to the next June 15th.

- Show 1st Days of Years: This method will use the starting day and

increment to the first of each year. For example, if the starting

day is on June 15th, it will go to the end of the first year and

then start fresh on the 1st of each year.

- Show Date Range: This option is used to just display a period

as a partial range. Enter a range above in the Report period

windows. Then when the sequence is run, only that period will be

hatched all in the same color and time.

- Custom Date Table: When a custom Date/Colors table is defined,

this option must be selected to use it. Custom Dates/Colors are

defined above.

- Custom Amount Table: When a custom Amount table is defined, this

option must be selected to use it. Custom Amounts are defined

above.

- Legend Scale: If the Draw Legend box is selected, this is

the size of the legend. Sizes from 50-100 should appear legible for

most mineplans with a dwg scale of 50.

- Hatch: This is the hatch that is used for drawing

in the blocks if the custom date or amount tables are not used. All

hatch patterns appear on the list, the most common one, solid,

appears at the top of the list for easy selection.

- Retreat Hatch: This is used for underground retreat

hatching. Disregard for surface mining.

- Divide advance/retreat display:

This is used for underground

retreat hatching. Disregard for surface mining.

- Scale: If a hatch pattern other than Solid is used,

this is the scale it will be drawn at. Sometimes trial and error is

needed to get the best scale, as different patterns look better at

different scales.

- Layer: This is the AutoCAD layer that the blocks

and outlines will be drawn in, if no other options are

used.

- Layer by year: The blocks and outlines will be layered by

year. The year will appear as a suffix to the layer

name.

- Layer by period: This option will put each period on its own

layer. If there are many periods, it will create many layers which

can be a hassle.

- Of, Sum for whole mine &

Stop at last period: These options are only active when

using the Custom Amount Table. The "Of" window is for selecting

what is being target for custom amounts. The options are similar to

Surface Production Timing: Total Tons, Key Tons, Waste Tons, Total

Area, Mined Area, Total Volume, Waste Volume, and User Grid. Sum

for whole mine will keep a running total for summation in the

report. Stop at Last Period will end the schedule at the last

entered row in the Custom Amount Table entered above.

- Split Report by Strata

Fractions: This option will utilize the tonnage and volume

factors stored as pit attributes and report out the volume and tons

of each named seam, not just composite Key Tons and Nonkey

volume.

Notes and Comments on Equipment

Timing:

Equipment Timing can mimic Surface Production Timing through

selection of "Custom Amount Table" at the base of the Report

Options dialog. This would be an alternative way of getting to

custom table amounts, since the equipment is removed from the

equation and is therefore irrelevant. This will target tons of

coal, yet report out how many dragline hours need to be scheduled

to uncover the coal.

If there are multiple seams (both Key and NonKey) assigned to one

bench, the program will report a tonnage and volume factor that

applies to each strata. This factor can be used in the User

Attributes to calculate the tonnage and volume of each separate

strata instead of just a composite number of Key and NonKey.

While Surface Production Timing reports total quantities broken

out by seams or specific strata, Surface Equipment Timing only

reports totals for all key strata (eg. coal) and overburden, unless

Split Report by Strata Fractions is turned on. However, Surface

Production Timing does report specific quantities (composited) for

each bench. Therefore, a 2-bench mining example will report

quantities for Bench 1 (coal C1) and Bench 2 (coal C2). With

sufficient benching, the individual strata quantities are retained.

For one-bench mining, all multiple strata are composited in the

final report.

To practice "what-if" scenarios, use "Undo Report" within the

Surface Timing dialog, which will remove the colored hatching,

allowing revision of equipment assignments and another practice

run.

Prompts

Select all pit polylines.

Select objects: Pick all polylines

Pull-Down Menu Location: Surface Mining menu, under

Surface

Keyboard Command: timepit

Related Commands: Surface Mine Reserves, Assign Directions,

Surface Project Manager, Assign Timing Grids, Import Timing Data,

Define Pit Attributes

Following is a detailed description

of each function on the Surface Timing window and subsequent

windows. After that is a step by step procedure for setting up for

the Surface Equipment Timing.

Following is a detailed description

of each function on the Surface Timing window and subsequent

windows. After that is a step by step procedure for setting up for

the Surface Equipment Timing.

The

Schedule Effect on Delay gives two choices: Schedule delay, where

the delay will take affect when the equipment is working. If the

calendar has the equipment off at that time, then the program waits

until it starts to work again, then schedules the delay. A Calendar

delay, where if the calendar has it off already, then that is all

it will do. It will not take it off additionally. The Due To option

provides Drawing Event Types to choose from. Choose the button with

"..." next to the Due To, to open the Drawing Event Types window.

To Add or Edit a type, the Capture/Timing Event Definition screen

provides names and productivity options. Anywhere the text drawn in

the Capture Layer is encountered in the drawing, the equipment will

be delayed by the Event Delay Length in shifts. The Productivity

Effect is the result of the delay. Not working is where the

equipment is completely down. Working is no change, and Not

Producing is where the equipment is in use, but no quantities are

being mined.

The

Schedule Effect on Delay gives two choices: Schedule delay, where

the delay will take affect when the equipment is working. If the

calendar has the equipment off at that time, then the program waits

until it starts to work again, then schedules the delay. A Calendar

delay, where if the calendar has it off already, then that is all

it will do. It will not take it off additionally. The Due To option

provides Drawing Event Types to choose from. Choose the button with

"..." next to the Due To, to open the Drawing Event Types window.

To Add or Edit a type, the Capture/Timing Event Definition screen

provides names and productivity options. Anywhere the text drawn in

the Capture Layer is encountered in the drawing, the equipment will

be delayed by the Event Delay Length in shifts. The Productivity

Effect is the result of the delay. Not working is where the

equipment is completely down. Working is no change, and Not

Producing is where the equipment is in use, but no quantities are

being mined.The Bottleneck

Parameters dialog box is found on the Surface Timing dialog under

the Bottleneck Params button. The Field Name you specify must

match one of the reserved words for volume, tons, or a user-defined

attribute. These reserved names can be found in the Edit User

Attributes section in the final report if they are not known. The

Threshold value is another name for the limit placed on the

attribute name. This limitation can be set for specific

equipment units, and it can be set for ALL units as well. To

set the unit preference order, ADD them to the dialog box to the

right under the Equipment Order heading. The order can be

changed by highlighting the unit (by selecting it with the left

mouse button) and picking the UP or DOWN button to the right.

Using the

fixed order as the restriction scheme, we will limit the tail

unit’s production every shift that the excess excavator capacity

exists. When the schedule is run, it checks the shift

capacity for each shift as the program times out the

progress. This slows the program down, showing a bottleneck

window with the dates counting by, but keeps the production

capacity in line with the desired production level. A report

is generated showing which unit is reduced and by how much. An

example report is shown here.

Using the

fixed order as the restriction scheme, we will limit the tail

unit’s production every shift that the excess excavator capacity

exists. When the schedule is run, it checks the shift

capacity for each shift as the program times out the

progress. This slows the program down, showing a bottleneck

window with the dates counting by, but keeps the production

capacity in line with the desired production level. A report

is generated showing which unit is reduced and by how much. An

example report is shown here.When the schedule

is run and the map is hatched showing the progress, note the

additional time periods for Units 3 and 4. This shows Units 3

& 4 have been held back while the other units worked at full

production. Unit 4 is not even working in some of the early months.

There is a progress bar to show the time elapsed and time remaining

for very large mineplans that take a while to run.