This next tutorial shows how to run Surface Equipment Timing through a series of benches in pits. This example starts with a pit layout mineplan and structure grids. It is assumed that you already know those operations. Then Design Bench Pit is run on the pits, creating output grids and a Grid Sequence File. Next the quantities for each bench will be calculated and stored in the pit polylines. Then the sequence of mining the benches and pits is assigned and run with Surface Equipment Timing.

Creating Pit Polylines

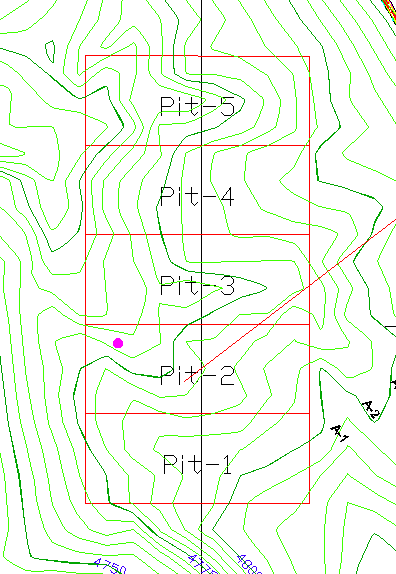

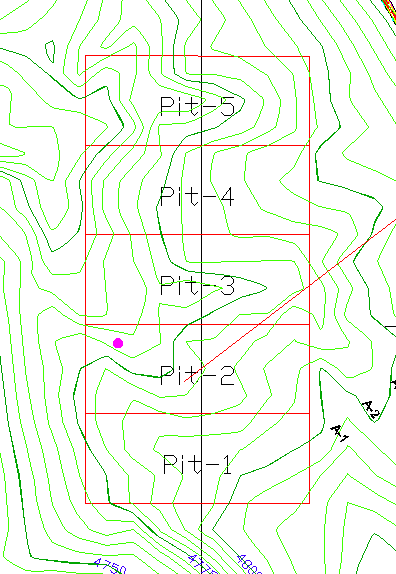

The first step is to sub-divide the overall pit perimeter into

smaller pits. In this example, the larger rectangular mine

perimeter is subdivided into 5 smaller pits, named Pit-1 through

Pit-5. These will be draped onto the bottom of the pit and benches

will go up and out from them. The command Pit Layout By Advance was

used to lay them out.

Assigning Pit Directions

In order to schedule the equipment through the pits, the direction

of mining needs to be assigned to each pit. In this case, the

direction of mining for each pit will be from left to right. First

draw a direction polyline through the pits from bottom to top. Then

run the Assign Directions command and use the Sequence method with

the LL option.

Assign direction using which method (<Auto>, Text,

Sequence, Polyline): S for Sequence

Select pit polylines to have direction assigned to:

Select objects: select the pit polylines

Select a direction polyline: pick the direction

polyline

Assign direction in which sequence (<LL>, LR, RL, RR):

LL

The pits now have direction assigned from west to east.

Design Bench

Pit

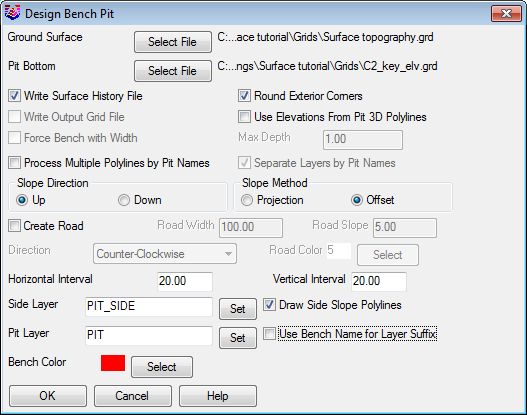

Using the pit perimeters as the inclusion areas, the program will

draw the 3D pit shells, output grids and calculate volumes for each

pit and bench. Before running Design Bench Pit, you need the pit

bottom perimeter polylines and grid files for the ground surface

and benches. In the first dialog, specify the ground surface grid

and the bottom elevation grid for the last bench. Also be sure the

Process Multiple Polylines by Pit Names and Write Surface History.

A grid file for each pit and each bench is created, and they are

automatically organized in the Grid History File (GSQ).

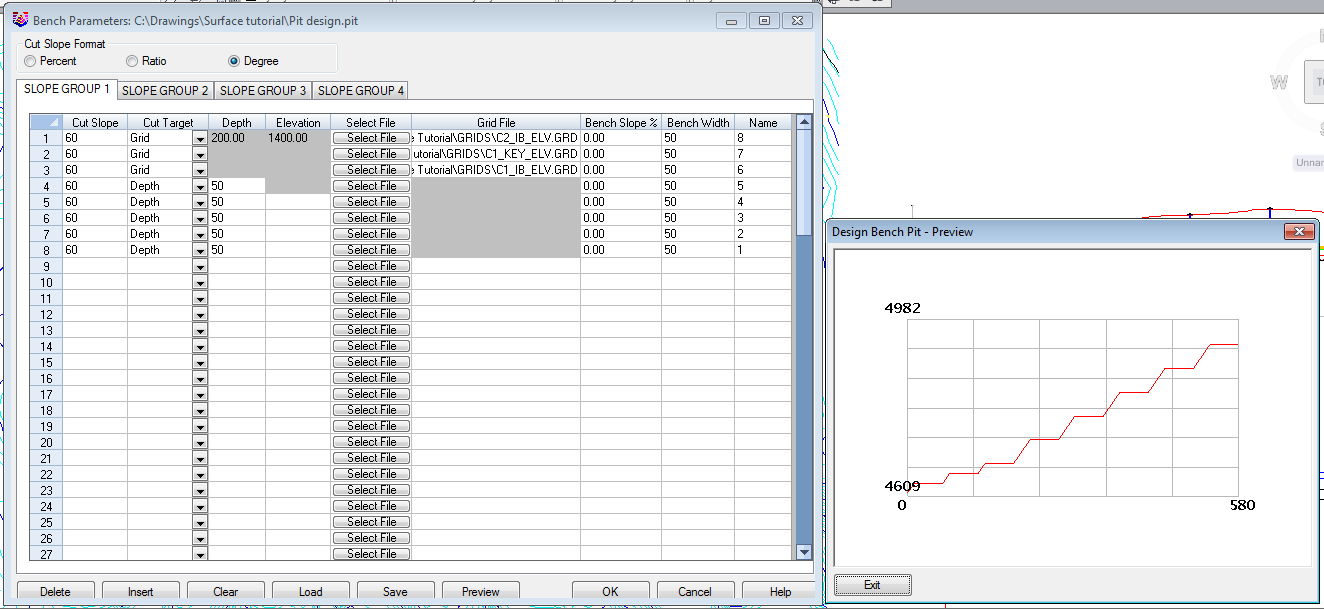

In the next dialog, you specify the side and bench slopes. The height of the side slopes can be specified by either a depth number or a grid file. In this case we will use grid files as well as by depth. Four different sets of slopes can be applied to different sides of the pit. For this example, the same slopes will be used on all sides. You can use up to 100 benches.

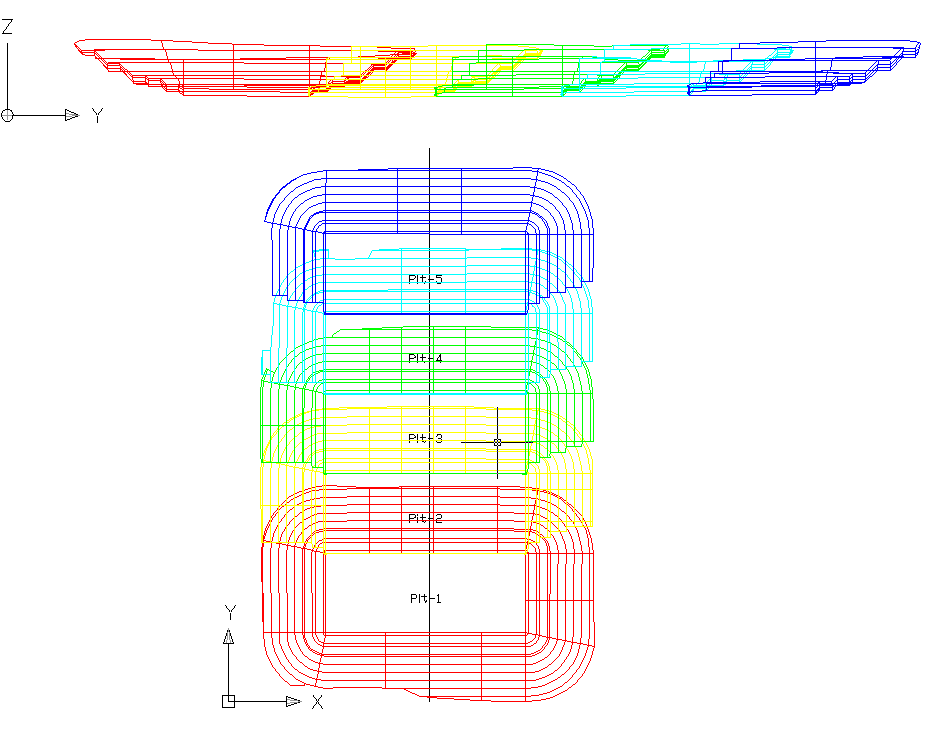

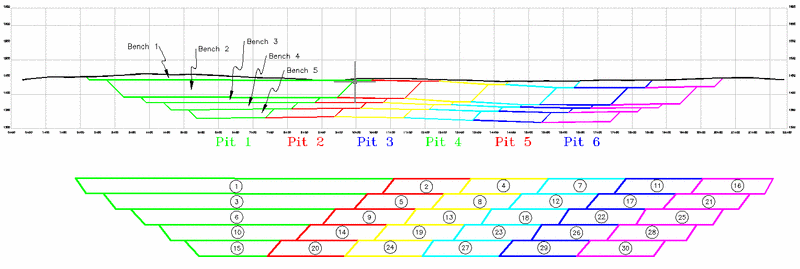

The output will look as such. Each pit is

in its own layer and colored differently. In the above view, the

pits are laid down on the side, to show the slope to each

grid.

The output will look as such. Each pit is

in its own layer and colored differently. In the above view, the

pits are laid down on the side, to show the slope to each

grid.

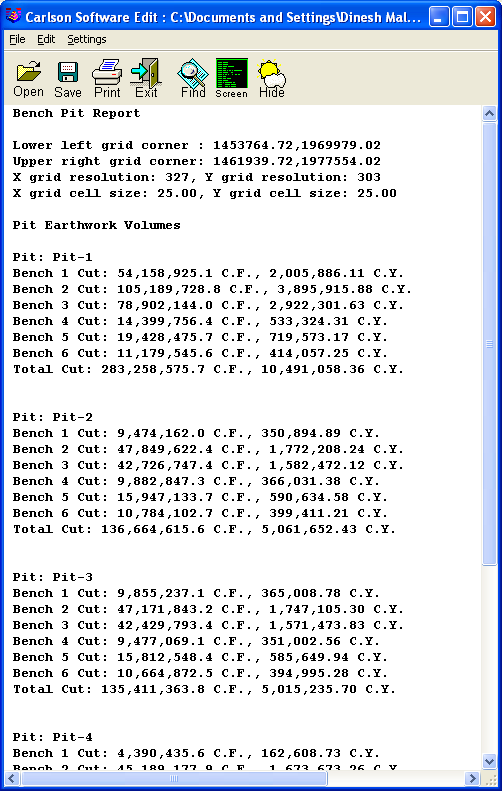

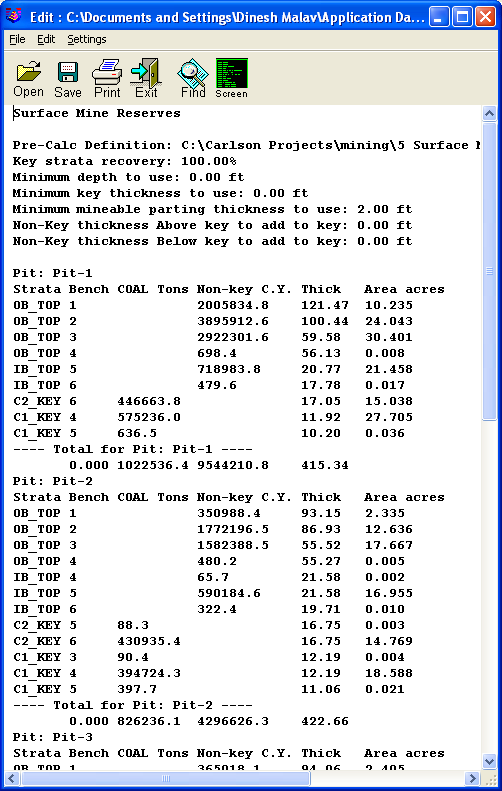

Each pit and bench quantity is reported in

the basic text report.

Each pit and bench quantity is reported in

the basic text report.

Assigning Bench Quantities

The next step is to store quantities in each pit for each bench

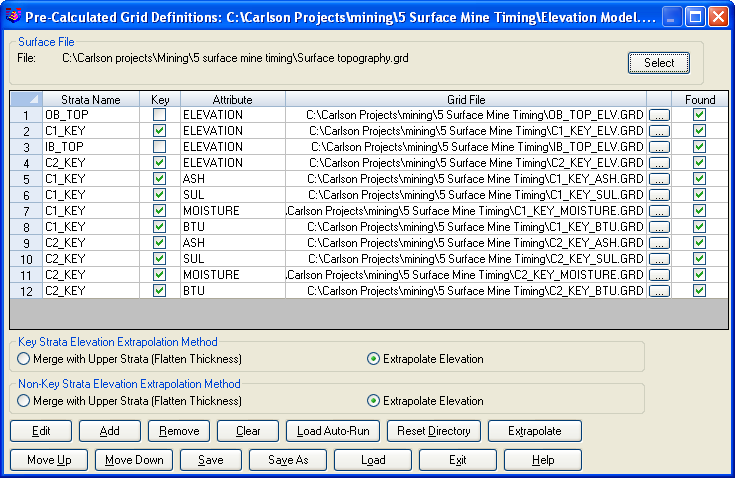

using the Surface Mine Reserves command. Before running this

command, you need to have a Pre-Calc Grid file (.PRE) in addition

to the GSQ history file. This is what determines the bench

quantities and automatically assigns them to the benches.. Use the

Define Pre-Calc Grids command to specify the grids as shown

below.

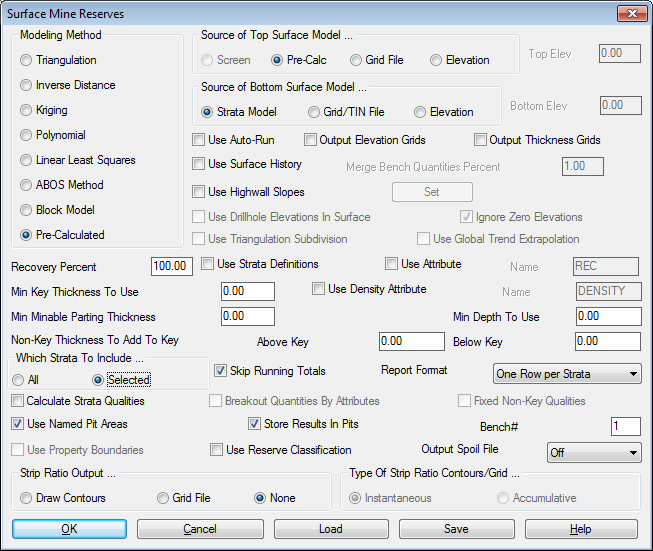

Then run Surface Mine Reserves. The dialog shown below appears.

Set the modeling method to Pre-Calculated and you can leave it set

to Bench 1. Since we are using the GSQ file, all five benches will

be assigned automatically. Turn on all the options you see

here.

Some important items to make sure are selected are Use Surface

History, Use Named Pit Areas, and Store Results in Pits. After

clicking OK on the dialog, specify the Pre-Calc file shown above.

Next the program prompts for the Grid History File created earlier

by the Design Bench Pit routine. The Merge Bench Quantities Percent

applies here. If there is some grid "bleeding" where one seam

bleeds into another bench due to the grid cell size, then this

option will put that material back into the correct bench, as long

as the amount is not less than this percentage.

Now the program will calculate the quantities of all the benches for all the pits. A report formatter allows you to optionally print or display the results. The quantities are stored in the pit polylines for scheduling. If you are not using the GSQ file, then you will have to run this for each bench number, with all the same options except set the Bench # to 2 and choose only Bench 2 from the strata list (Selected Strata turned on). Then repeat this command a third time using bench 3 etc. That is what is nice about the GSQ file, it does them all at once, even calculating and assigning the layback slope volume accordingly. Shown next is the pit by pit and bench by bench volume report.

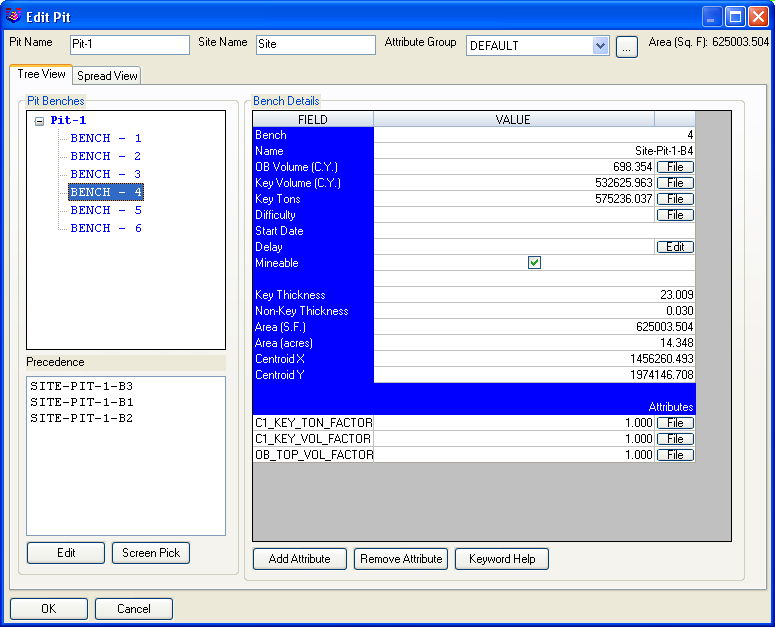

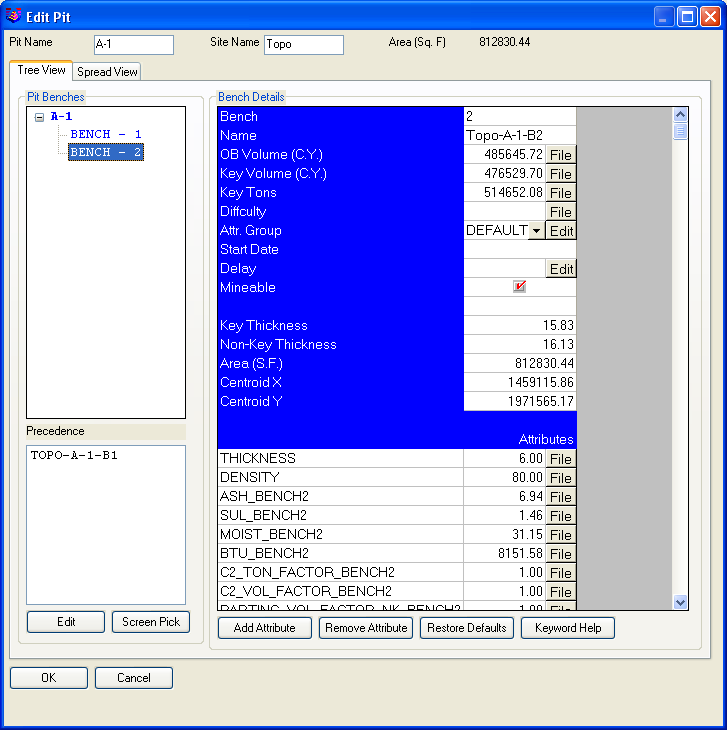

These values are now stored in the pits and can be verified with

Edit Pit under Boundary. Click inside any one of the pits to see

the values. All benches can be accessed by selecting the bench

number in the tree view on the left of the dialog or by selecting

the Spread View tab to view data for all benched at a time.

Surface Project Manager

The Surface Project

Manager can be accessed under Reserves/Timing dropdown menu. It

allows user to define Equipments, Timing Calendar, Pit Attributes

as well as other essential parameters to be used in the

timing.

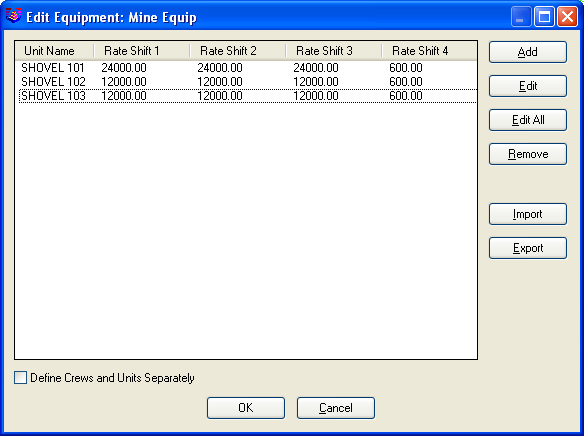

Define Equipment

Select the Edit Set in Project Manager to create an equipment

definition to mine the pits. This example will use three shovels.

This command shows a list of existing equipment definitions. Choose

the Add button and fill out the dialog as shown below for a three

shift operation for all shovels. Shovel1 mines 24000 CY/shift and

Shovel 2 and Shovel3 mines 12000 CY/Shift.

Define Calendar

The next step is to define the calendar. By default, both units are

working every day, every shift. It is your job to take off

holidays, weekends and maintenance down time.

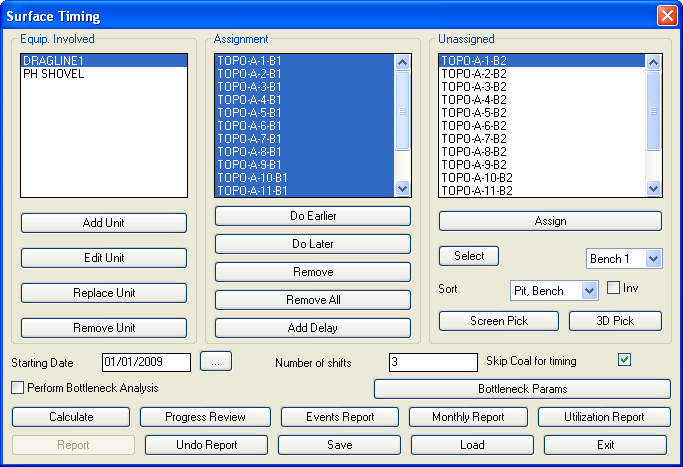

Surface Equipment Timing

The Surface Equipment Timing command schedules the equipment

through the pits. The first dialog shows three list boxes for the

equipment, the pits assigned to the equipment and the unassigned

pits. The pit benches are listed as site name - pit name - bench

number. For example, "Site 1-Pit 1-2" is for bench 2 in pit1. To

set the equipment to use, choose the Add Equip button and select

the equipment name defined in the last step.

The sequence of mining the pit benches must be assigned. In this case, we want a 5-step staircase that advances through the pits. By default the pit benches are sorted in the unassigned list by pit number then bench number. To arrange the pit benches in the staircase order, choose the Sort dropdown list and select 5-Bench Staircase. Then pick the Select button followed by the Assign button. This will assign the pit benches to the equipment in staircase order. In this example, just manually select the first pit/bench, and holding the CTRL button down, select every other one. Then hit Assign, assigning them to Shovel1. Then highlight Shovel2, hit Select All, and assign the remaining pits/benches to Shovel2.

Shown above are 6 profiles of the bench pits. They have been manually connected with polylines and the pits and benches are labeled to show the "blocks". This is to illustrate the real bench width in cross section view. The lower graphic shows this profile exaggerated and numbered exactly as each block is going to be sequenced in the 5 bench staircase method. The sequencer automatically sorts them in this order.

The 3D Pick option can be used to graphically select each bench and pit in the order to be mined. It is very useful for short-term scheduling. Just select 3D Pick, rotate it to an useful 3D view and then double click on each block. It will be removed and assigned to the highlighted unit.

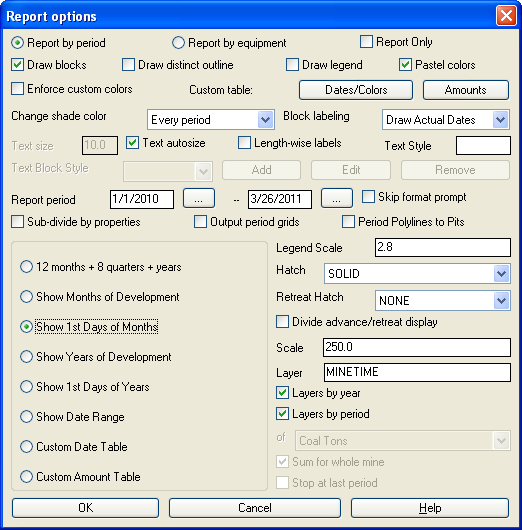

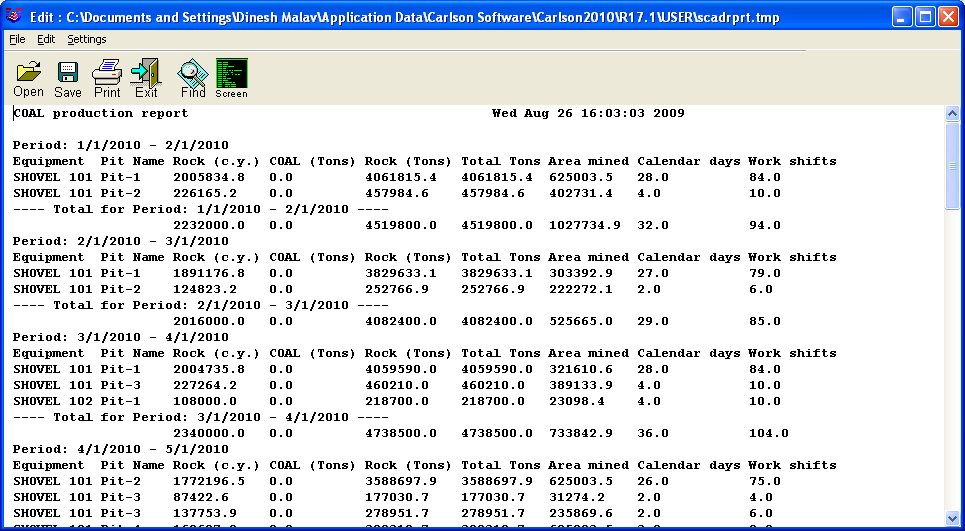

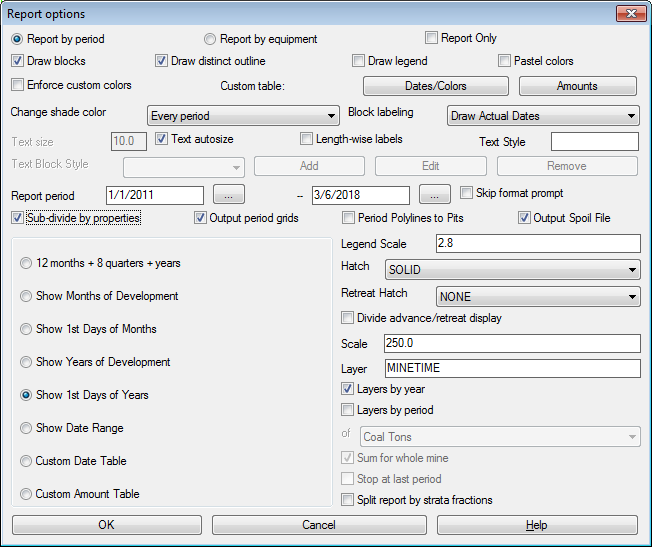

When all the pit benches are assigned as shown in the dialog, click the Calculate button. The program will then run the equipment through the pits and report the completion date. Then click the Detailed Report button. This brings up the Report Options button.

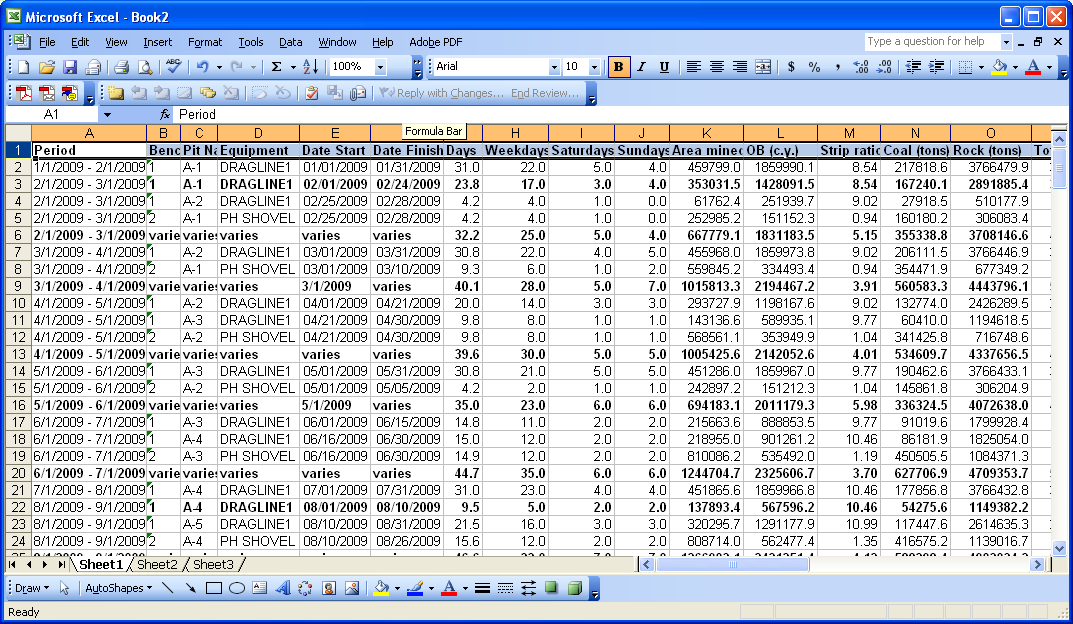

In this case, the report period is set to Show 1st Days of Months. This will give a monthly schedule from the first of each month. Following is a report by monthly period. This can be formatted in many ways and exported to Excel.

Multi-Bench Mining Example Setup:

The defining of equipment, crews and equipment calendar are

(potentially) one-time operations. Similarly, the making of the

Geologic Model needs be done only once in advance of numerous

timing runs. Surface Equipment Timing, also distinct from Surface

Production Timing, allows multi-bench mining by use of different

equipment or the same equipment mining different benches, with

different production rates. Since single-bench mining is a subset

of multi-bench mining, this will illustrate the command with a

multi-bench example. Surface Mine Reserves is one of three methods

to place quantity and quality information into the pits, by bench.

This example will use Surface Mine Reserves. If there are two

benches, Surface Mine Reserves must be run twice, one time

for each bench. The dialog within Surface Mine Reserves should be

completed as follows for Bench 1:

The

key is to choose "Selected" strata (for benching) as well as "Use

Named Pit Areas" and "Store Results in Pits". You should also

select "Calculate Strata Qualities" to assign quality information

to the pits. If single-bench mining is conducted, you may omit the

"Selected" option. Other items in the dialog are set according to

user preference. Note the option "Output Thickness Grids". If this

is not selected, total quantity and composited quality information

is placed in the pits, and mining across a single pit is

proportional. However, if the "Make Thickness Grids" option is

selected, mining across the pits picks up the varying of the

overburden thickness, coal thickness and quality information. For

small pits or "blocks" as they are sometimes called, storage of

total information will still lead to reliable results. Thickness

grids are recommended for large and long pits, where the thickness

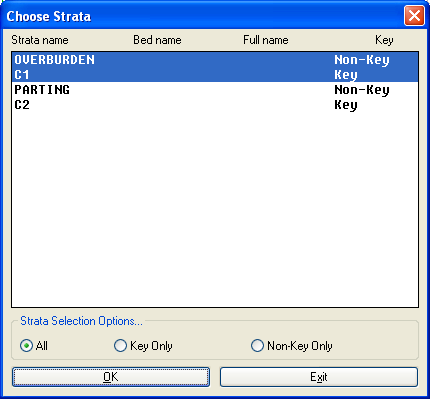

will vary. The choice of "Selected" strata requires that the user

select which strata will be mined in Bench 1. The following Choose

Strata dialog at will appear:

The

key is to choose "Selected" strata (for benching) as well as "Use

Named Pit Areas" and "Store Results in Pits". You should also

select "Calculate Strata Qualities" to assign quality information

to the pits. If single-bench mining is conducted, you may omit the

"Selected" option. Other items in the dialog are set according to

user preference. Note the option "Output Thickness Grids". If this

is not selected, total quantity and composited quality information

is placed in the pits, and mining across a single pit is

proportional. However, if the "Make Thickness Grids" option is

selected, mining across the pits picks up the varying of the

overburden thickness, coal thickness and quality information. For

small pits or "blocks" as they are sometimes called, storage of

total information will still lead to reliable results. Thickness

grids are recommended for large and long pits, where the thickness

will vary. The choice of "Selected" strata requires that the user

select which strata will be mined in Bench 1. The following Choose

Strata dialog at will appear: Holding the CTRL or SHIFT key down, will select Overburden

and C1 to mine down to the bottom of the first coal (C1). Bench 2

would be comprised of Parting and C2. Following two runs of Surface

Mine Reserves, new information has been added to the pits. Pits

contain up to three categories of information: pit name (verified

by using "Identify Pit Polylines"), pit direction and pit

quantities/qualities organized by bench. Pit quantities and

qualities are needed only for Surface Equipment Timing, and can be

verified using the command "Edit Pit". For example, the information

in Edit Pit is shown below. Select the "Attribute" option to reveal

the quality attributes.

Holding the CTRL or SHIFT key down, will select Overburden

and C1 to mine down to the bottom of the first coal (C1). Bench 2

would be comprised of Parting and C2. Following two runs of Surface

Mine Reserves, new information has been added to the pits. Pits

contain up to three categories of information: pit name (verified

by using "Identify Pit Polylines"), pit direction and pit

quantities/qualities organized by bench. Pit quantities and

qualities are needed only for Surface Equipment Timing, and can be

verified using the command "Edit Pit". For example, the information

in Edit Pit is shown below. Select the "Attribute" option to reveal

the quality attributes.

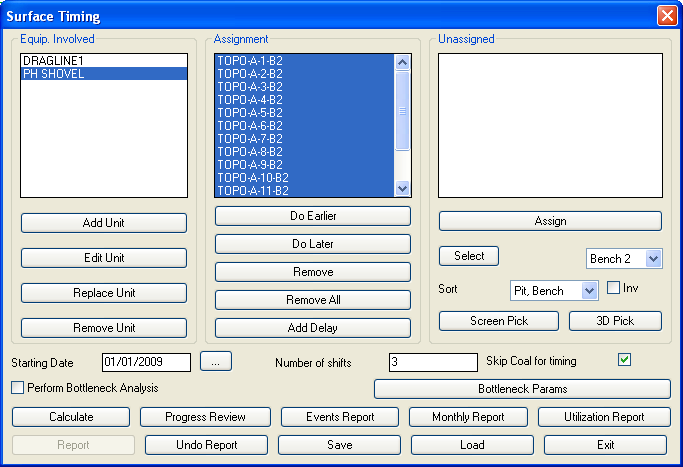

It is also

important to note the option "Skip Coal for timing" at the lower

right of the dialog box. Here you can base all progress on the

NonKey overburden and parting only, on the assumption that the

loaders or other equipment digging the coal will "keep pace" with

the equipment removing the overburden and interburden. If "Skip

Coal for timing" is not selected, the coal volume will be included

in the total quantity mined by the equipment. We can add a second

piece of equipment, then highlight it within the Surface Timing

dialog and assign all the remaining pits to it (Select All or Bench

2, then Assign). Note also that we can add a delay between

completing the Bench 1 pit and beginning the Bench 2 pit. Delays

are automatically inserted below the highlighted pit, so if a pit

is highlighted, a delay will be added below it that can be moved up

or down also. There is a prompt to add this as a calendar or

schedule delay (described above). Shown below is the

assignment for Bench2.

It is also

important to note the option "Skip Coal for timing" at the lower

right of the dialog box. Here you can base all progress on the

NonKey overburden and parting only, on the assumption that the

loaders or other equipment digging the coal will "keep pace" with

the equipment removing the overburden and interburden. If "Skip

Coal for timing" is not selected, the coal volume will be included

in the total quantity mined by the equipment. We can add a second

piece of equipment, then highlight it within the Surface Timing

dialog and assign all the remaining pits to it (Select All or Bench

2, then Assign). Note also that we can add a delay between

completing the Bench 1 pit and beginning the Bench 2 pit. Delays

are automatically inserted below the highlighted pit, so if a pit

is highlighted, a delay will be added below it that can be moved up

or down also. There is a prompt to add this as a calendar or

schedule delay (described above). Shown below is the

assignment for Bench2. To complete

the calculation, fill in the Starting Date (if the default is not

correct), then click on Calculate. This leads to a completion date

and the option of a unit report or going directly to the Report

Options screen. The Unit Report is very instructive because it

highlights when equipment has been idled. Our Bench2 dragline is

waiting each time for the "slower" Bench1 dragline to complete

bench 1 before it can launch into bench 2. The planner could try

lower rated equipment, or reverse the assignments of the equipment,

or simply re-shuffle the assignments in any desired manner to

maximize efficiency. The last step is to choose "Report" when

returned to the Surface Timing dialog which brings up the Report

Options dialog.

To complete

the calculation, fill in the Starting Date (if the default is not

correct), then click on Calculate. This leads to a completion date

and the option of a unit report or going directly to the Report

Options screen. The Unit Report is very instructive because it

highlights when equipment has been idled. Our Bench2 dragline is

waiting each time for the "slower" Bench1 dragline to complete

bench 1 before it can launch into bench 2. The planner could try

lower rated equipment, or reverse the assignments of the equipment,

or simply re-shuffle the assignments in any desired manner to

maximize efficiency. The last step is to choose "Report" when

returned to the Surface Timing dialog which brings up the Report

Options dialog. This

example will show the first days of months. This leads to the

final hatching shown below as bench 1(the bench 2 layers were

frozen for better appearance), as well as the quantity report which

can be formatted many different ways and exported to Excel or

Access:

This

example will show the first days of months. This leads to the

final hatching shown below as bench 1(the bench 2 layers were

frozen for better appearance), as well as the quantity report which

can be formatted many different ways and exported to Excel or

Access: