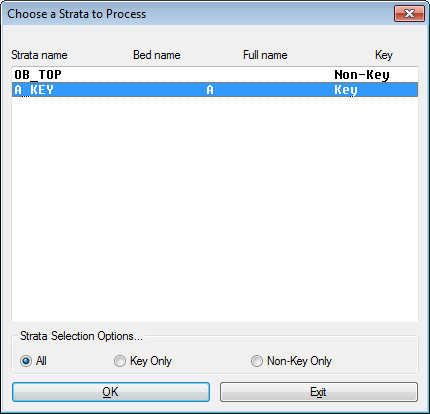

The command Selected Strata Quantities brings up

this screen to select the strata or bed to analyze.

The command Selected Strata Quantities brings up

this screen to select the strata or bed to analyze.Two Types of Compositing are described here. (1) Single Seam or Ore Body compositing where the seam has been sampled at various intervals, and (2) Combinations of Several Seams Separated by Interburden.

(1) Single Seam or Ore Body

Large ore deposits such as limestone and thick beds of coal are often sampled at multiple points within the single ore body or bed. For long-range planning and reserve estimates, it is often desired to obtain the composite quality for the entire mineral deposit within an inclusion perimeter. For short-range planning, the mine engineer needs to know what quality will be obtained in a particular vertical segment of the ore body or seam, also within a defined perimeter.

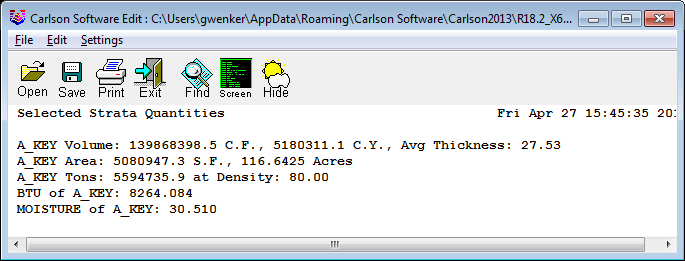

Entire Seam Composites In the first example, a body of ore has been sampled at 3 to 4 points vertically, as seen in the geologic columns. Note in the geologic columns (generated with Draw Geologic Column) that all the ORE has been assigned bed "A". This will "lump" the various ore samples into one "bed". If the bed name is not assigned when the holes are drawn, then this can be accomplished by the commands "Assign Bed Names" or "Fill in Bed Names". Then the command Selected Strata Quantities will produce this report (showing composite A tons) when the A_Key strata is chosen singly and the inclusion perimeter is selected. Compositing of the single A bed is automatic.

Note: The program will not composite qualities for a strata name

that is repeated, unless there is a bed name grouping them

together.

The command Selected Strata Quantities brings up

this screen to select the strata or bed to analyze.

The command Selected Strata Quantities brings up

this screen to select the strata or bed to analyze.

Vertical Composite

Zones

In

the next example, a vertical zone of ore has been defined as the

upper part of the ore body or "A" bed from 4130 elevation and up.

The "floor" of the vertical cut in this case is flat, following the

4130 elevation. This might correspond to a mine plan where the base

of the first of two cuts is designed to hit elevation 4130 within

the entire pit. The technique required is to divide bed A into two

beds. This is done by the command "Split Bed" within

Strata/Bed Utilities under Drillhole. The prompting is as

follows:

Command: splitbed

Split strata method

[<Elevation>/Grid/Thickness]? E

Select the Drillholes for bed

split. Select the

holes

Select objects: Specify opposite

corner: 3 found

Enter name of the bed to

split: A

Rename bed or assign key/non-key

status [<Name>/Status]? Name

Enter new name for the upper part

of the bed: A

Upper

Enter new name for the lower part

of the bed: A

Lower

Enter a split elevation:

4130

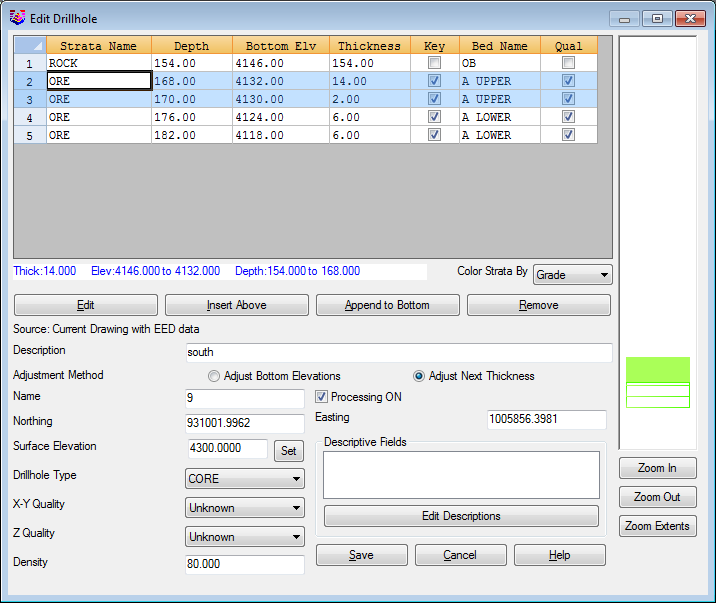

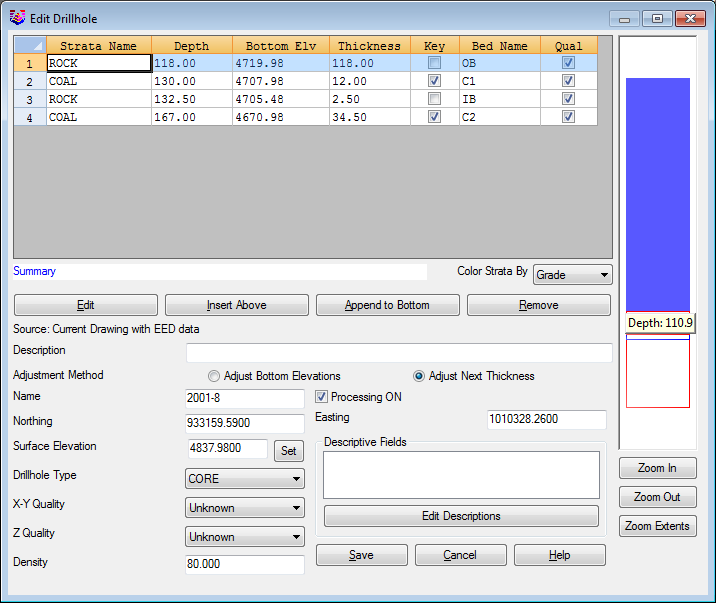

This shows a drillhole before splitting the A seam into an A Upper and A Lower.

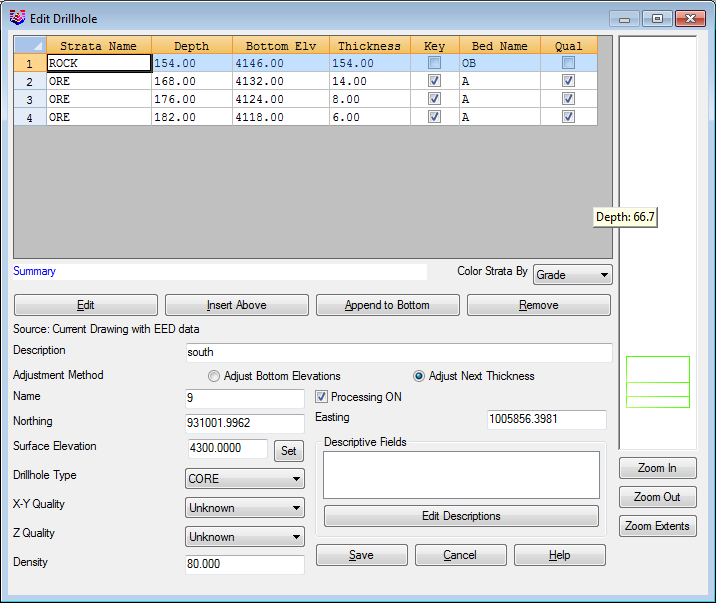

Here is

the same drillhole, viewed within "Edit Drillhole" after the

command "Split Bed". Notice the new Bed Names, A Upper and A

Lower.

Here is

the same drillhole, viewed within "Edit Drillhole" after the

command "Split Bed". Notice the new Bed Names, A Upper and A

Lower.

The

result is a new base of A Upper seam. It is important to note that

the quality characteristics of the original ore zone have been

applied identically to the new ore zones that have been renamed to

A Upper and A Lower. The rest of the ore zone, the lower 12.5 feet,

has become part of A Lower. If a drillhole does not reach as low as

4130 elevation, then all the ore remains in the A Upper bed and is

unaffected. Conversely, if the ore never exceeds elevation 4130 in

a particular drillhole, then it is assigned bed A Lower for all the

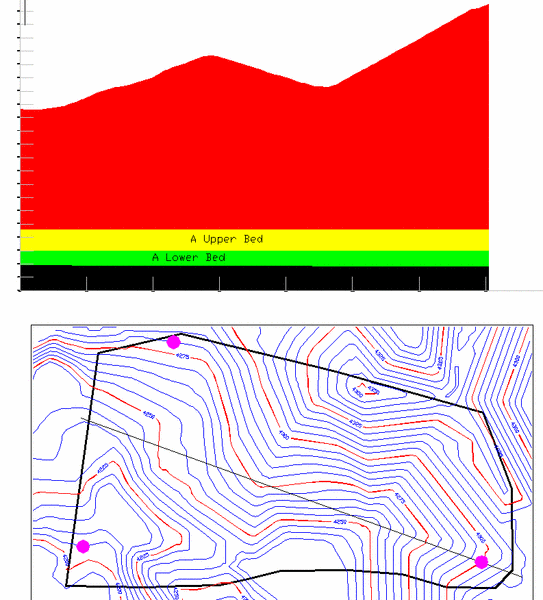

ore sample points. Here is a Fence Diagram showing the two

divisions of the bed, at elevation 4130.

The

result is a new base of A Upper seam. It is important to note that

the quality characteristics of the original ore zone have been

applied identically to the new ore zones that have been renamed to

A Upper and A Lower. The rest of the ore zone, the lower 12.5 feet,

has become part of A Lower. If a drillhole does not reach as low as

4130 elevation, then all the ore remains in the A Upper bed and is

unaffected. Conversely, if the ore never exceeds elevation 4130 in

a particular drillhole, then it is assigned bed A Lower for all the

ore sample points. Here is a Fence Diagram showing the two

divisions of the bed, at elevation 4130.

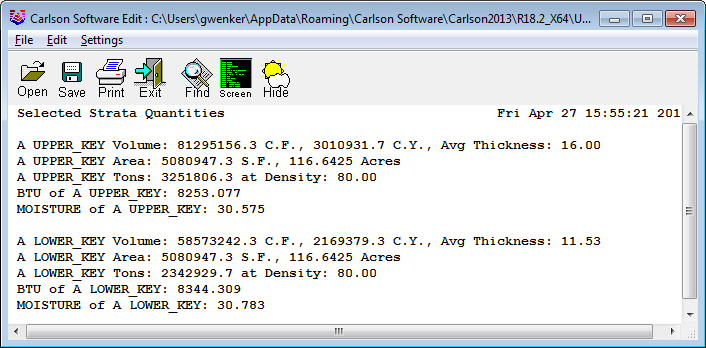

Now the command "Selected Strata Quantities" can

be run. Ironically, you don't select the "composite" option because

you want to calculate the A Upper and the A Lower beds distinctly.

You select them one at a time from the dialog box. This leads to

the result shown here in the report. Adding the tons calculated

here: 3292460 + 2351700 = 5644160 calculated above, when the bed

was just A. This is a good check to make sure the quantities

match.

Now the command "Selected Strata Quantities" can

be run. Ironically, you don't select the "composite" option because

you want to calculate the A Upper and the A Lower beds distinctly.

You select them one at a time from the dialog box. This leads to

the result shown here in the report. Adding the tons calculated

here: 3292460 + 2351700 = 5644160 calculated above, when the bed

was just A. This is a good check to make sure the quantities

match.

Split Bed by Grid

File

Split Bed by Grid

File

In the previous example, we chose to split the bed by elevation.

If, by contrast, the goal was to leave 5-feet of lower ore in place

to be removed by different equipment, then the vertical demarcation

is not a fixed elevation but a grid file defined as base of ore

plus 5 feet. This grid file is made by using "Make Strata Grid

Files" to make the base of ore, then using Grid File Utilities (in

the DTM or StrataCalc menu) you would add a value of 5-feet and

re-save the grid file as Oreplus5.grd or some such name. This new

file would be used to delineate the split elevation between the A

Upper and A Lower beds.

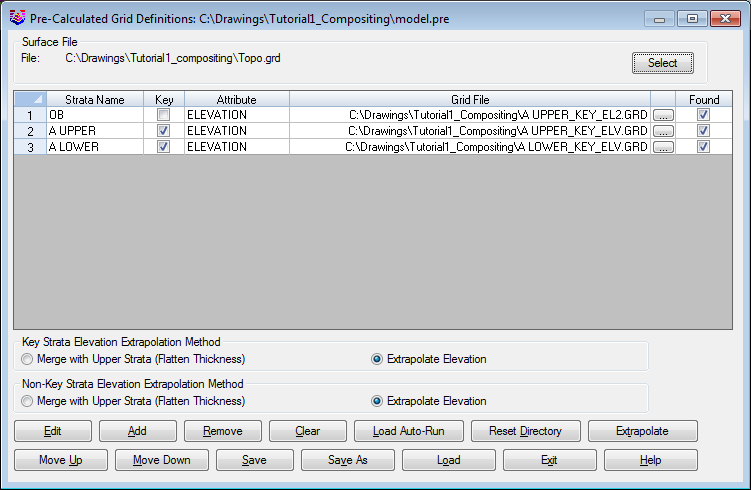

Advanced Mine Module

Techniques

In the above example, the command "Selected Strata Quantities" was

used. This is an "on-the-fly" selection approach, where the

drillholes are selected each time the command is run. It does not

take advantage of stored grid files in the Geologic Model file

(.PRE), which is the essence of the Advanced Mine Module. To apply

the above procedures to the Advanced Mine Module, follow this

sequence:

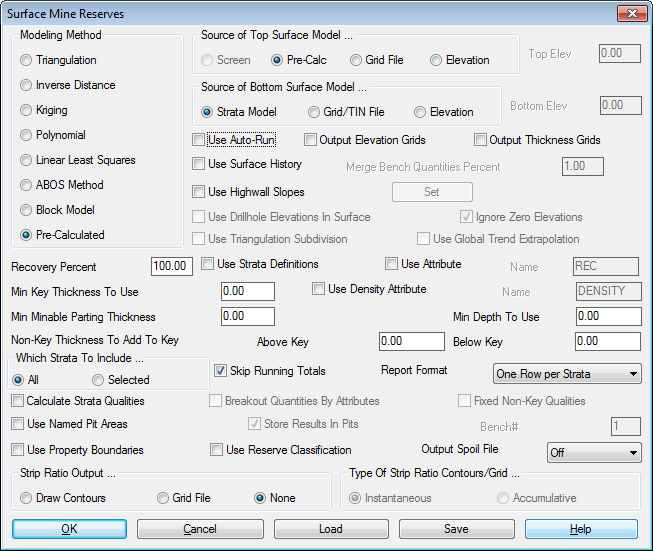

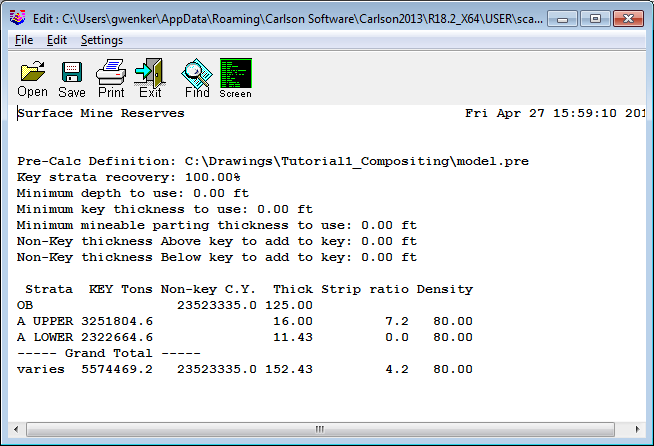

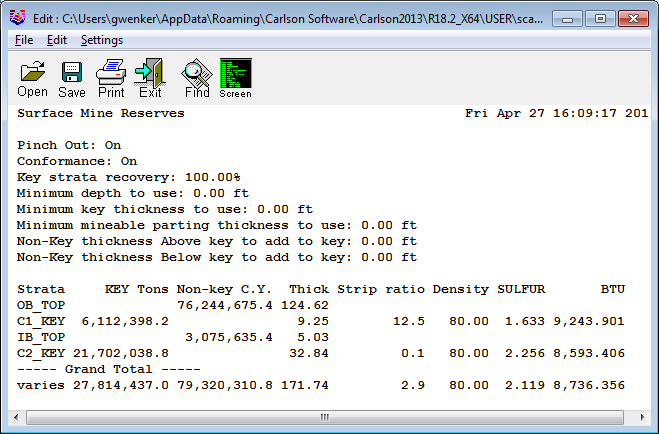

Then run Surface Mine Reserves, selecting Geologic Model as the

modeling method. You will obtain the same quantities for each bed

as reported from the command "Selected Strata Quantities".

The advantage of setting up grid files is that multiple, prenamed pits can be run within Surface Mine Reserves, and the reporting can be formatted and expanded upon at the user's discretion, even dumped to Excel and Access. The various options within Surface Mine Reserves can be fine-tuned, such as recovery percentage, density and dilution. Furthermore, "grand totals" are obtained where the qualities and volumes/tonnages of beds A Upper and Lower are composited back into the total reserve values. (Indeed, this is the exact procedure used for multiple seams with interburden.)

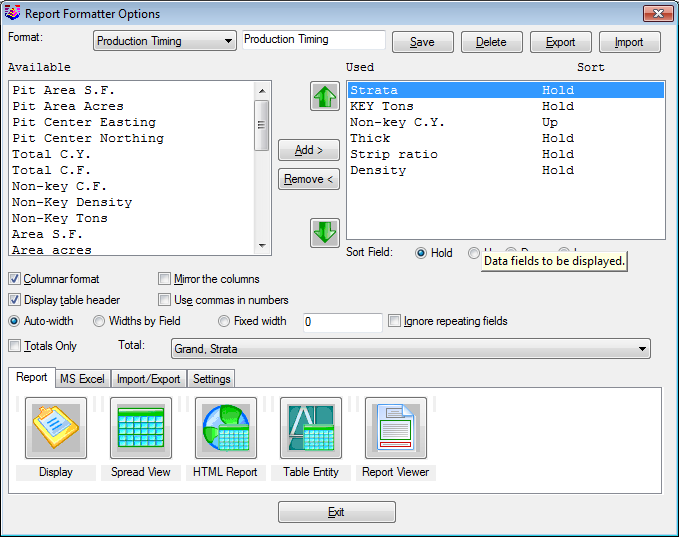

Shown here is a formatted report for the single inclusion

polygon representing the pit in our example. Slight differences in

values versus "Selected Strata Quantities" is a function of the

difference in gridding locations and cell sizes. With stored

Geologic Model grids, quantities and qualities will be fully

repeatable.

(2) Combinations of Several Seams Separated by Interburden

In the mining of stratified deposits it is very common to have several seams separated by interburden. Surface mines must consider the composite tonnage, composite strip ratio and composite quality in any reserve study or short-term mining plan. Two main issues come to mind—how deep to mine, and when to mine and remove interburden as if it were Key. Let's look at a coal deposit example.

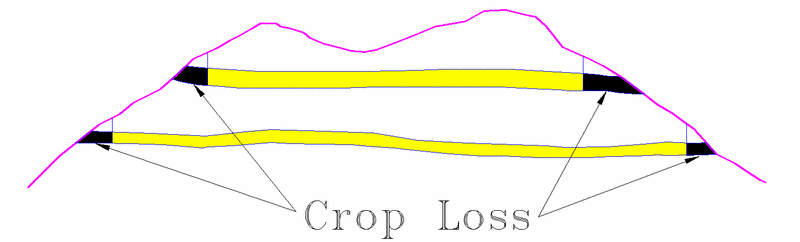

How Deep to Surface Mine

Strip ratios change as each lower seam is taken, and quantities of

coal increase. The goal is to get as many lower seams as possible,

but not so many that interburden thicknesses and strip ratios

increase excessively, or quality degrades. Currently, about a 15:1

strip ratio approaches the maximum feasible ratio for

cost-effective mining. Higher ratios do occur and will certainly

occur if the market price of coal increases. Coals are said to

"outcrop" at the surface, with "crop loss" referring to unmineable,

"weathered" coal at the hillside edge. Usually the crop loss is

around 12 to 15 feet measured vertically from the surface. It is

often deeper in valleys or even small hillside ravines and

"drains", due to accumulation of debris and erosion. On "points" or

ridges, crop loss may be only 10 to 12 feet, particularly in

hardrock conditions. The Surface Mine Reserves routine is designed

for estimating reserves and includes a built-in crop loss parameter

(measured vertically from the surface), appearing as "Min Depth to

Use". Here is a graphic representing the crop loss on the side of a

hill.

A conservative engineer or geologist would enter

15 feet to obtain a "low-ball" estimate. Someone looking

aggressively for all the coal they could possibly obtain might

enter 10 or 12 feet for the vertical crop loss. Be aware that with

steep 1.5:1 hillside slopes, a 10' vertical crop loss translates to

15' measured horizontally from the hillside. In 3:1, gently sloping

terrain, a 10' vertical crop loss translates to 30' measured

horizontally from the hillside. If the natural terrain slopes on

the order to 2:1 to 3:1 or more, it is reasonable to use a lower

vertical crop loss value for "Min Depth to Use". The value used is

strictly a judgment call and is ideally based on observations at

the mine. There is no option to have a variable crop loss. That is

best handled by defining a "Strata Limit Polyline". See the

"OutCrops and SubCrops" case study. In many regions, shallow coals

will "subcrop" as they hit an alluvial deposit or as it nears the

surface and is decomposed due to oxidation and

weathering.

A conservative engineer or geologist would enter

15 feet to obtain a "low-ball" estimate. Someone looking

aggressively for all the coal they could possibly obtain might

enter 10 or 12 feet for the vertical crop loss. Be aware that with

steep 1.5:1 hillside slopes, a 10' vertical crop loss translates to

15' measured horizontally from the hillside. In 3:1, gently sloping

terrain, a 10' vertical crop loss translates to 30' measured

horizontally from the hillside. If the natural terrain slopes on

the order to 2:1 to 3:1 or more, it is reasonable to use a lower

vertical crop loss value for "Min Depth to Use". The value used is

strictly a judgment call and is ideally based on observations at

the mine. There is no option to have a variable crop loss. That is

best handled by defining a "Strata Limit Polyline". See the

"OutCrops and SubCrops" case study. In many regions, shallow coals

will "subcrop" as they hit an alluvial deposit or as it nears the

surface and is decomposed due to oxidation and

weathering.

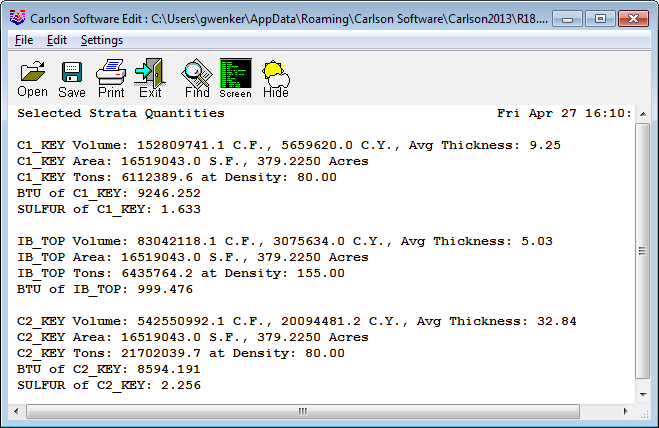

Another Example: Getting Composite

Qualities

The Surface Mine Reserves command automatically computes composite

qualities and strip ratios on all Key strata, providing "Calculate

Strata Qualities" is selected in the dialog box (dialog shown

earlier above). The low SULFUR and BTU values for OB and IB are not

included in the composite quality for SULFUR and BTU. This is

because OB and IB are not defined as KEY. When C1 and C2 are

imported or placed in the drawing, they are defined as KEY strata.

Alternately, the KEY designation can be assigned and changed using

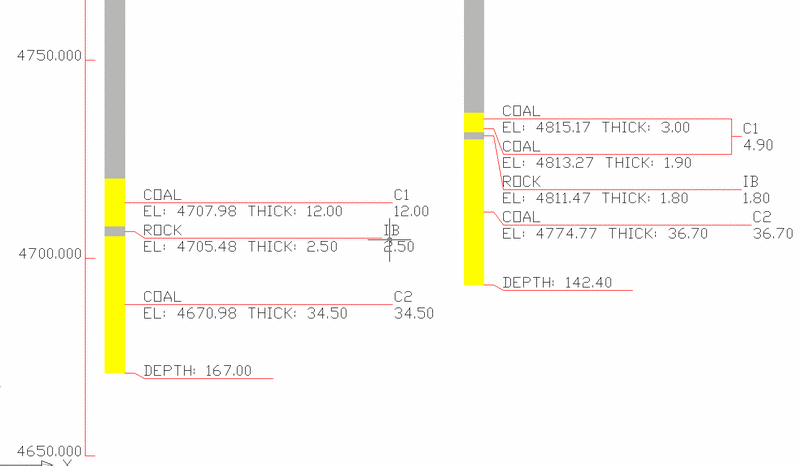

the command "Define Strata". Shown is a drillhole example of this

dataset, and the composite KEY quality report.

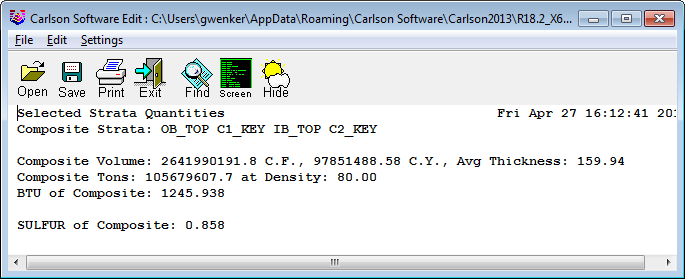

By contrast, composite qualities can also be computed using the

command "Selected Strata Quantities", but this routine will

composite any selected strata, key or non-key. In our example, if

all 4 beds are selected, the composite BTU is only 1245. All of the

above calculations were based on screen-selection of the drillholes

(not grid files), and use of Triangulation modeling. (Sulfur was

not entered for Nonkey beds).

Partings: When to Mine and When to

Waste

Drillholes 8 and 10 below have 2.5 and 1.8 feet of interburden,

respectively, between coals C1 and C2. It makes sense to take the

thin interburden with the coals, even though this will dilute some

qualities (and maybe improve others). Surface Mine Reserves has an

option called "Min Minable Parting Thickness" designed specifically

for this purpose. The effect on qualities is also shown below. This

result is obtained automatically by designating 2.0 feet as the

"minimum minable parting thickness", meaning that any lesser

thickness will not be separated as waste but will be included as

coal.

To obtain interburden qualities and to factor them in to the

composite quality, it was critical that qualities be associated

with non-key strata. This is accomplished within the command

"Define Drillhole" or a setting on the main Surface Mine Reserves

screen for Fixed NonKey Qualities.

In our example, the interburden had a density set at 150 within Define Strata, and had BTU values in the 1000 range, and sulfur in the 0.5 range. The net effect of including the thin interburden was to improve sulfur and degrade BTU. If sulfur under 1.0% is the more critical value in meeting quality requirements, and less BTU is satisfactory, then the user could accept thicker interburden. Compare these quality values with the ones calculated above and see how the SULFUR is lower and the BTU is also lower, but still within spec. Just try several reserve runs to see what the parting thickness cut off can be.