Case Study: Block Modeling by Quality Attributes

This tutorial takes a set of drillholes and goes through the steps

that create the block model. The different grades are defined in

the Grade Parameter File. Blocks are drawn and viewed in 3D for

analysis. Cross sections are cut through the blocks and volumes by

grade are calculated with Surface Mine Reserves. Finally, the

Optimized Pit Design is found with the Lerch-Grossman

algorithm.

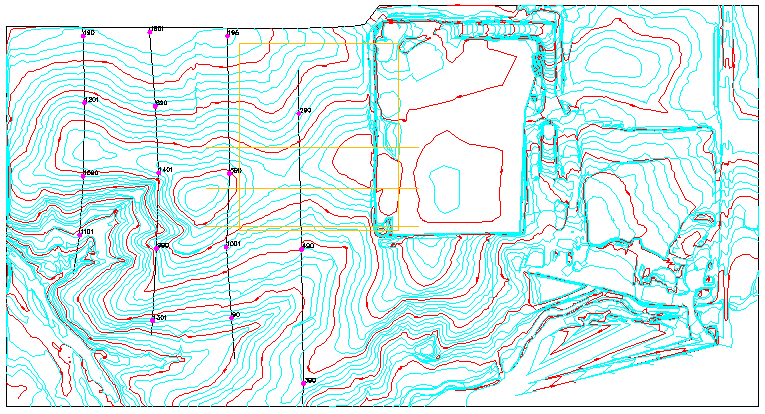

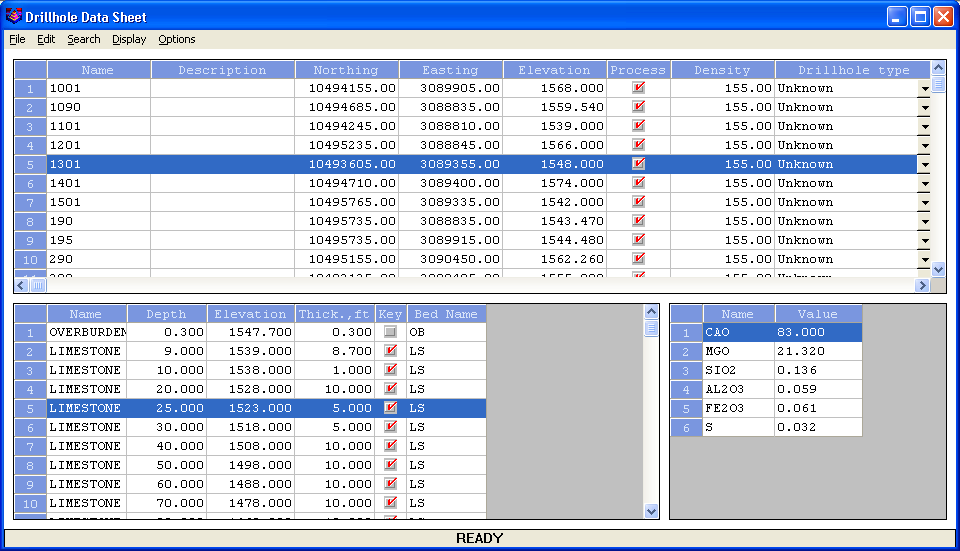

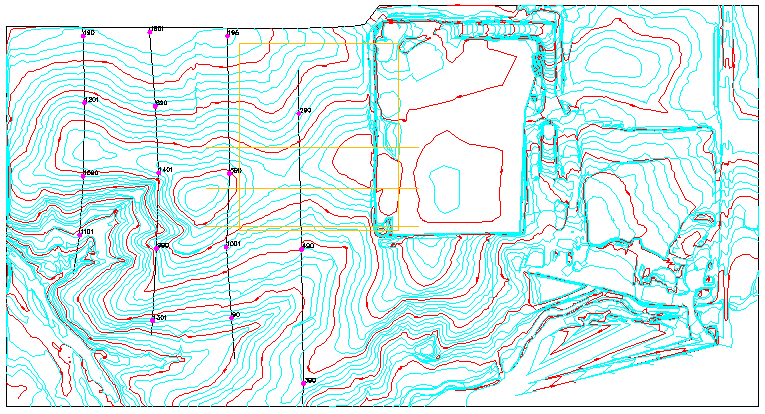

Drawing with Drillholes

The first step is to import the drillholes and name the beds based

on how the seams are to be modeled. This example is a limestone bed

with a thin layer of overburden, so there are just two main

material types in the drilling, OB and LS are the bed names. The

drillholes have already been imported for this example. That

process is documented in other documents. There are 16 drillholes

in this drawing. The drawing name for this tutorial is Block Modeling.dwg. Shown here are the

plan view of the topography and the drillholes, and also the

drillhole datasheet to display the drilling data.

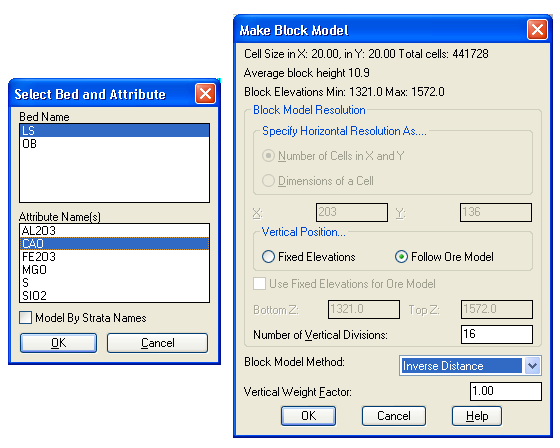

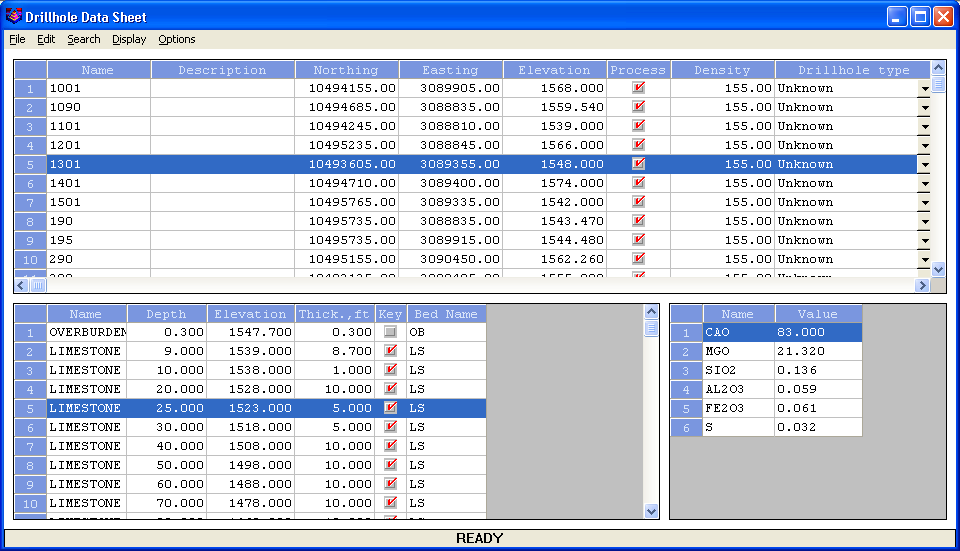

Make Block Model

This command is used to create the block model from the drillholes.

The first selection is to choose the Bed Name to model, and then

the quality or qualities. Just one quality attribute may be used,

or several at once. In this example, the LS bed and the CaO

attribute will be modeled, as shown in this window. It needs a grid

file to set the horizontal block sizes, so either pick the position

from screen, and put in a dimension for X,Y, or copy an existing

grid for positioning. For this one, the Surface Topo.grd can be copied for a

position, which is 20x20 in dimension.  The second window sets the block height and

modeling method. There are two distinct methods for setting the

block height. They can be set to a fixed elevation and size which

is independent of the beds, or can follow the top and bottom of the

ore model from the drillholes. This creates almost a stratified

block model where the elevations of the blocks follow the top and

bottom of the ore elevations. This is like a hybrid of both

strata and block modeling. If there are not any strata, such as in

a gold or copper deposit, then the Fixed Elevations method is

preferred. Both methods work the same. If using the Fixed

Elevations method, to set the block height, the top and bottom of

the model are entered, with the number of samples chosen to set the

average block height, which is calculated and displayed at the top.

In this screen, if the Number of Vertical Divisions is set to 16,

the average block height listed above is 10.9. This should work

well with the horizontal size of 20x20, giving an average block

size of 20x20x10. This example will use Inverse Distance as the

modeling method with a vertical factor of 1. Selecting OK builds

all of the blocks and puts them in the BLK file. Choose a name for

the BLK file, such as LS_CaO.BLK.

The second window sets the block height and

modeling method. There are two distinct methods for setting the

block height. They can be set to a fixed elevation and size which

is independent of the beds, or can follow the top and bottom of the

ore model from the drillholes. This creates almost a stratified

block model where the elevations of the blocks follow the top and

bottom of the ore elevations. This is like a hybrid of both

strata and block modeling. If there are not any strata, such as in

a gold or copper deposit, then the Fixed Elevations method is

preferred. Both methods work the same. If using the Fixed

Elevations method, to set the block height, the top and bottom of

the model are entered, with the number of samples chosen to set the

average block height, which is calculated and displayed at the top.

In this screen, if the Number of Vertical Divisions is set to 16,

the average block height listed above is 10.9. This should work

well with the horizontal size of 20x20, giving an average block

size of 20x20x10. This example will use Inverse Distance as the

modeling method with a vertical factor of 1. Selecting OK builds

all of the blocks and puts them in the BLK file. Choose a name for

the BLK file, such as LS_CaO.BLK.

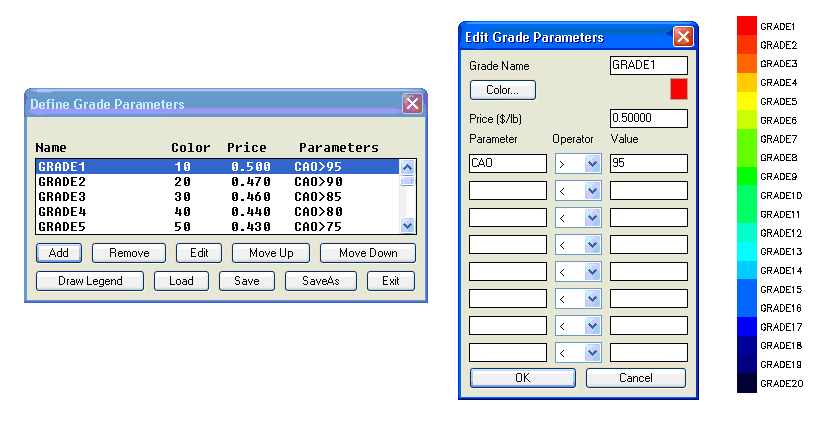

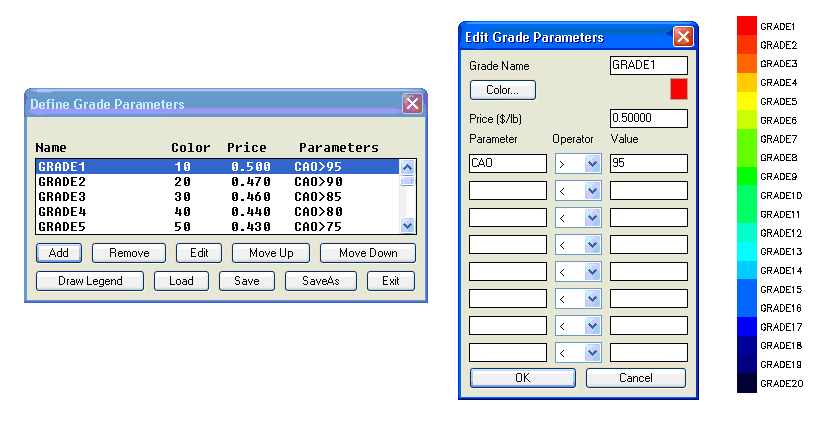

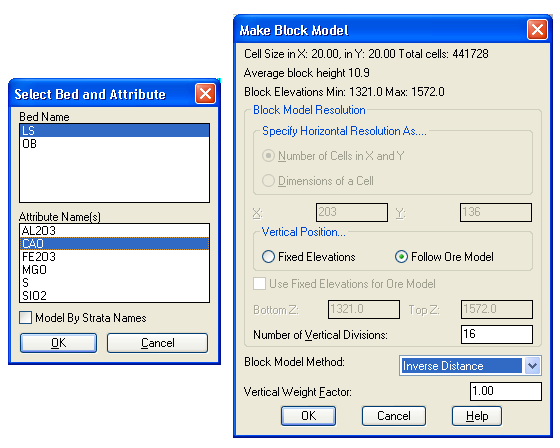

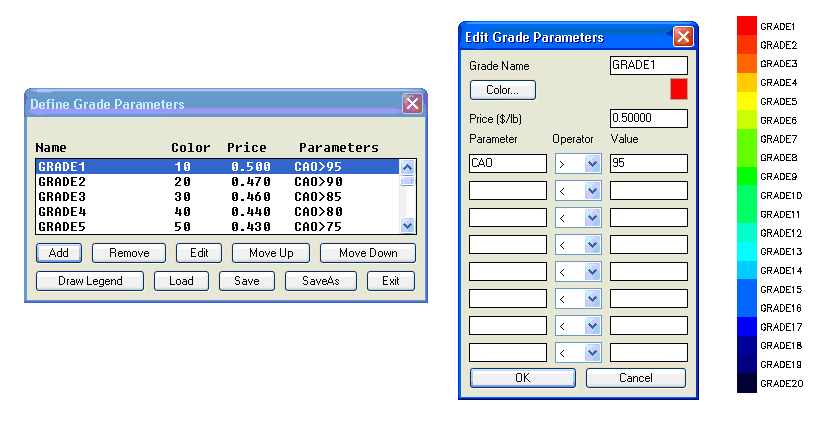

Define Grade Parameter File

This command defines the grade ranges of the ore. This is what

defines the blocks for colors and divisions for cross sections and

volumes. There is a Draw Legend button to put it on the map. The

price per pound is also defined here for the cost model, and that

will be used for the optimized pit design. Also notice that there

are 8 blanks for the various Parameters where the combination of

the several attribute ranges can define the grade. For example the

CaO > 90 and MgO< 15 defines the "High-Grade". For this

example, just the CaO is defined for the different ranges. If

another range is already defined, then the program will just use

what is available. That is why just the ">" option is used

below, starting at the highest grade and working down.

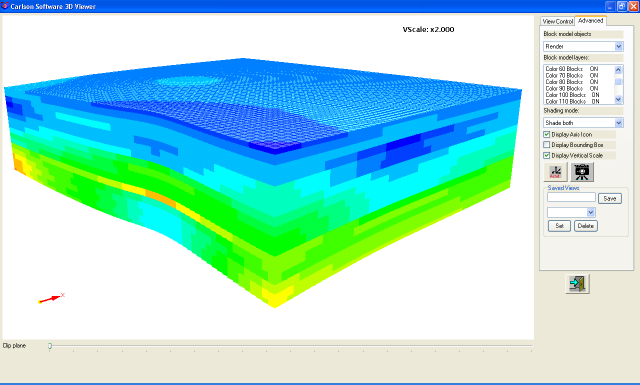

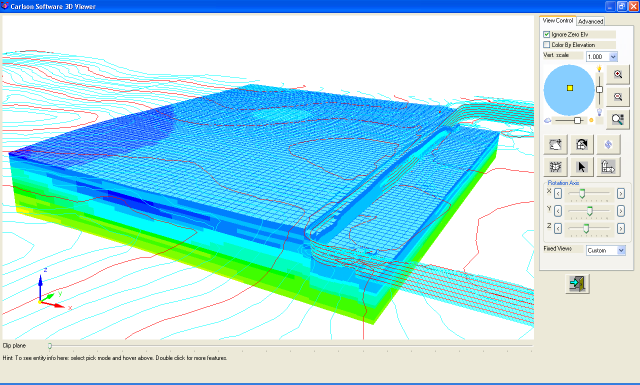

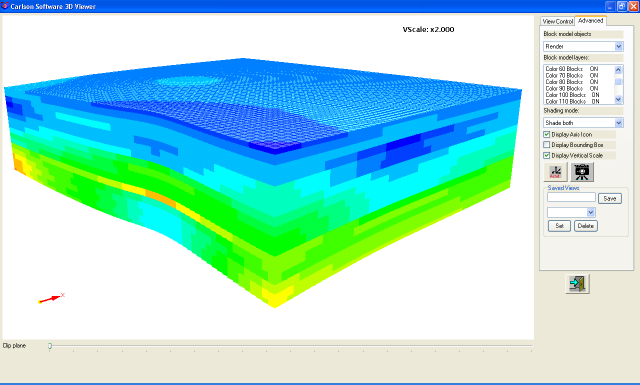

Block Model Viewer

Block Model Viewer

Now that the block model is built and the grade ranges are defined,

the model can be inspected and viewed in 3D to check it for any

problems. If the model is large, it is best to use an inclusion

polyline to view just a subset of the entire model. In the Advanced

Tab, there is a way to turn the various blocks on and off like

layers. Just click on the line to turn on or off and the blocks are

removed or added from the screen. This allows 3D views to see what

the quality is inside the middle of the blocks. Notice in this

example there are just green and blue blocks remaining.

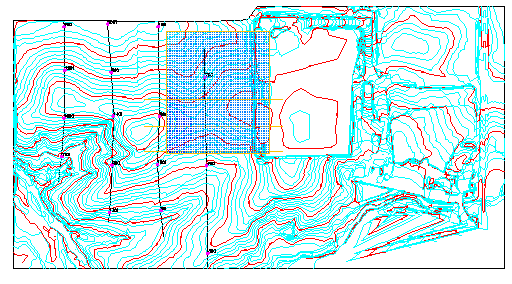

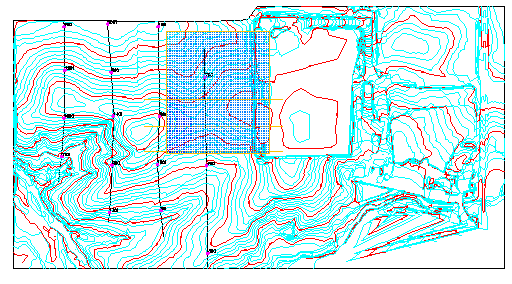

Draw Block Model

This is not a required step, but is convenient to place the blocks

in the drawing permanently. This command will draw the blocks on

screen in CAD as nodes or “dots”. These nodes can then be brought

into the 3D Viewer window and rendered the same as the Block Model

3D Viewer does. The nice option in this command allows to have a

top and bottom limiting surface to crop the blocks. That way if

just the blocks on a certain bench want to be viewed, use just the

top and bottom grids of that bench, or even the topography, and an

inclusion perimeter, to contain the blocks to draw, and ultimately

view. After selecting the file, just leave all set to "YES" on the

Draw Block Model screen. The nodes and contours drawn in CAD can be

viewed with the 3D Viewer Window as seen below.

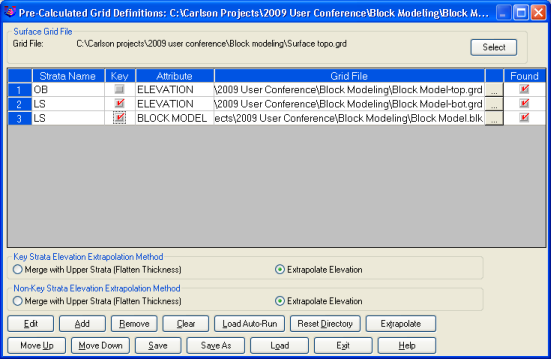

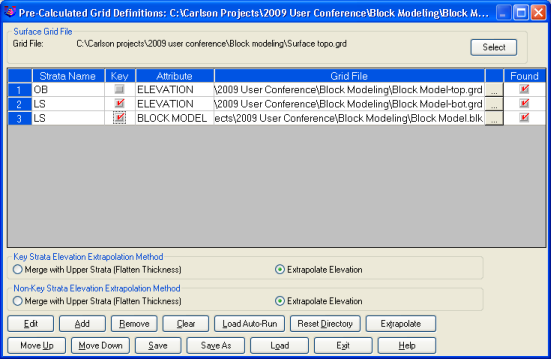

Define Geologic Model

This step is necessary to combine the block model with the surface

topo and any top or bottom elevation surfaces that will make up the

entire model. The procedure for strata models is to just add the

elevation grids as normal, and then add the BLK block model file to

the appropriate interval. Flat elevation grids can be used for

this, if it isn’t a stratified model that has roofs and floors,

like many hard rock metal mines and quarries that aren’t

stratified.

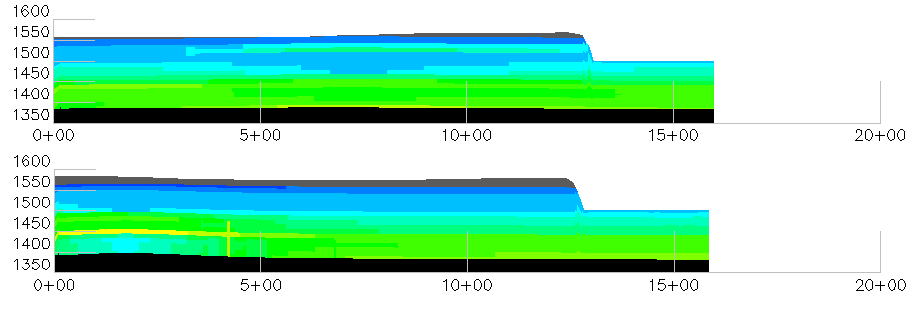

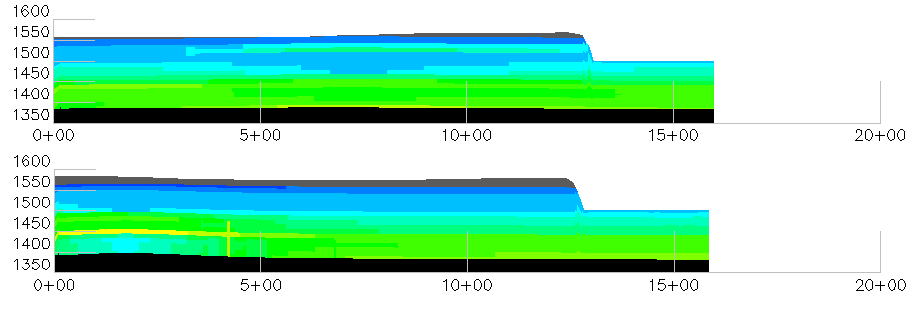

Fence Diagram

Now that the entire model is built and checked, a Fence Diagram can

be drawn to see the geology and blocks in section view. Fence

Diagram has an option to Hatch by Block Model. This can be drawn in

two ways. The initial section shows it on a 2D Grid, the second one

can be seen in 3D where it draws and hatches the fence in 3D below

the line, in Real World Coordinates. Shown below are two fence

diagrams from the drawing, on a 2D grid. Notice the coloration of

the blocks based on grade of limestone.

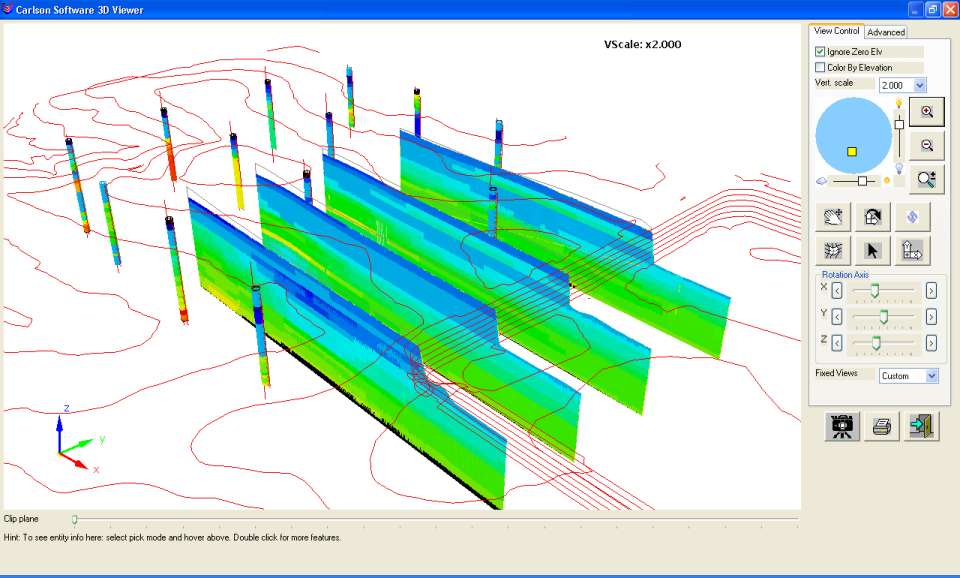

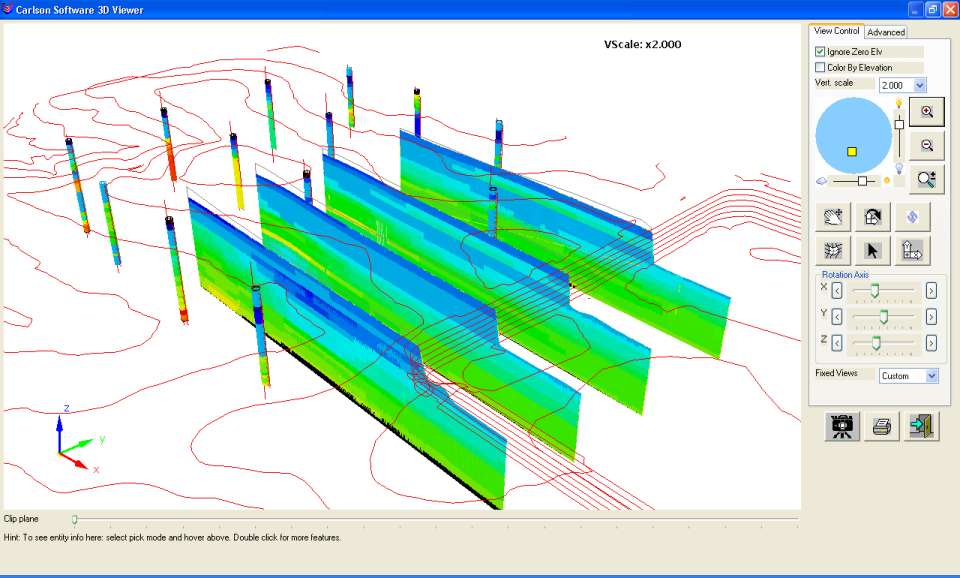

There is also an option to draw the

Fence Diagrams in 3D using the Real World Coordinates setting. When

this is viewed in the 3D Viewer Window along with 3D Geologic

Columns, the result is very useful to visualize the geologic

deposit as shown below. The Draw Geologic Column command will draw

the drillholes as 3D columns, and they can also be colorized by the

Grade Parameter File. Notice how the coloration in the drillholes

corresponds to the coloration in the fence cross-sections,

indicating and good modeling estimation.

There is also an option to draw the

Fence Diagrams in 3D using the Real World Coordinates setting. When

this is viewed in the 3D Viewer Window along with 3D Geologic

Columns, the result is very useful to visualize the geologic

deposit as shown below. The Draw Geologic Column command will draw

the drillholes as 3D columns, and they can also be colorized by the

Grade Parameter File. Notice how the coloration in the drillholes

corresponds to the coloration in the fence cross-sections,

indicating and good modeling estimation.

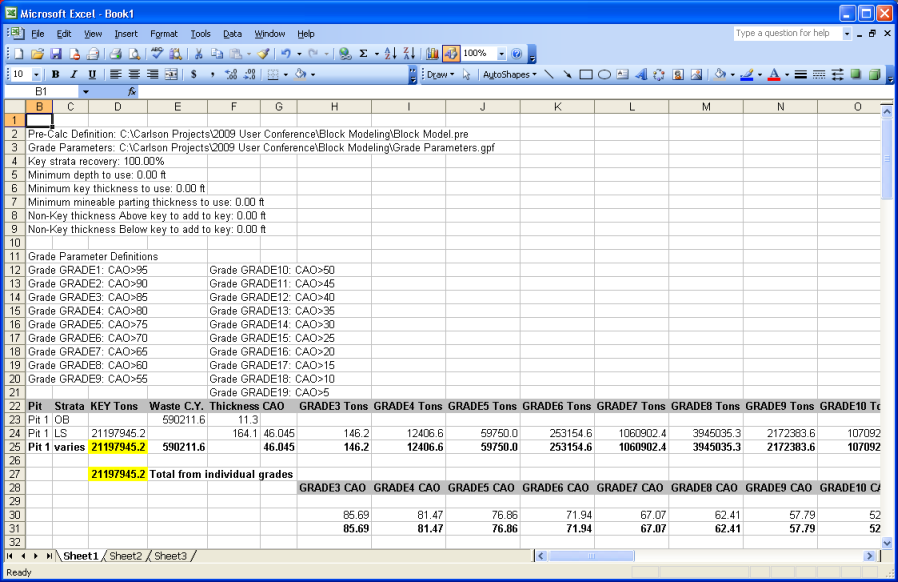

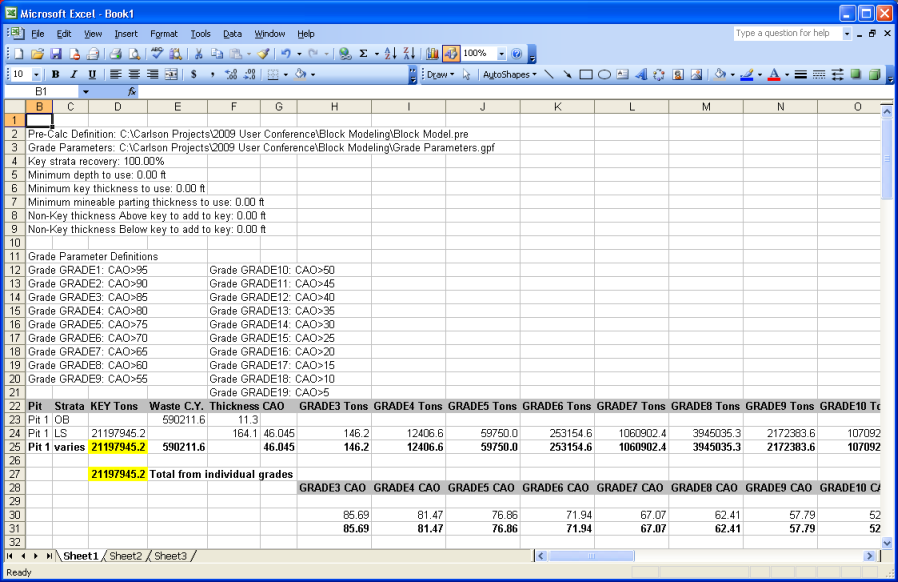

Surface Mine Reserves

The next step is to get the volume and tons of the different grades

of limestone with the Surface Mine Reserves. There is one check box

to turn on that will report the tons by grade, it is Breakout

Quantities by Attributes. This will not only give total tons of the

limestone, but also the tons in the various grades. Here is how the

window should appear.  Shown here is the report of the data

dumped into Excel using the Report Formatter. Notice how the total

Key tons match the individual grade tons added up in the yellow

cells. This is a good check to make sure all grades are accounted

for in the report. Also confirm that each grade's CaO falls in line

with the values defined in the Grade Parameter File.

Shown here is the report of the data

dumped into Excel using the Report Formatter. Notice how the total

Key tons match the individual grade tons added up in the yellow

cells. This is a good check to make sure all grades are accounted

for in the report. Also confirm that each grade's CaO falls in line

with the values defined in the Grade Parameter File.

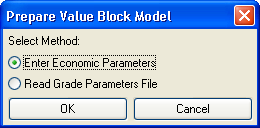

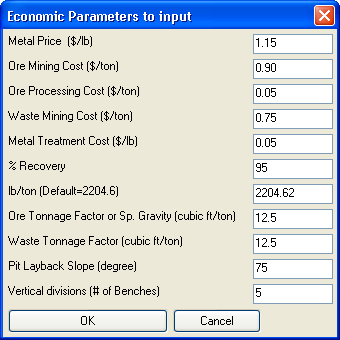

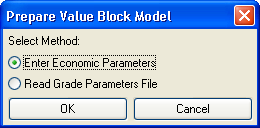

Prepare Value Block Model

Now to find the optimized final pit of profitable mining, we will

run this command to create a value block model, where each block is

assigned a cost associated with it. Once this value block model is

created, then the Optimized Pit Design can be run. First, select

the geologic block model to analyze. This is the file used in the

steps above. Then choose either to use the Grade Parameter file, or

to Enter the parameters on screen here. For this run, the Economic

Parameters will be entered. Select the Surface

Topography grid when prompted to do so. It will use this to

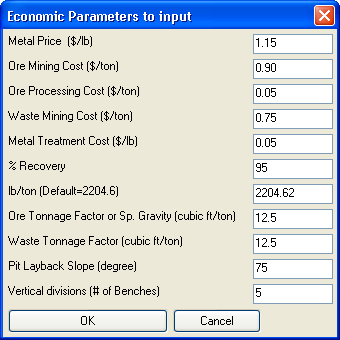

calculate the overburden on top of the blocks.  Enter in the Economic Parameters. Shown here is

a sample of the costs associated with the various mining stages.

This writes the value block model, where each block now has a value

assigned to it whether it is profitable or not. This file is named

Value Block Model.BLK.

Enter in the Economic Parameters. Shown here is

a sample of the costs associated with the various mining stages.

This writes the value block model, where each block now has a value

assigned to it whether it is profitable or not. This file is named

Value Block Model.BLK.

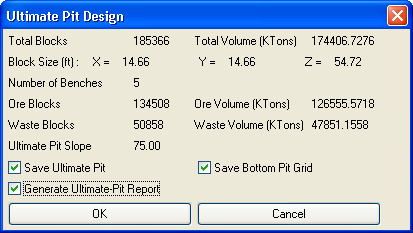

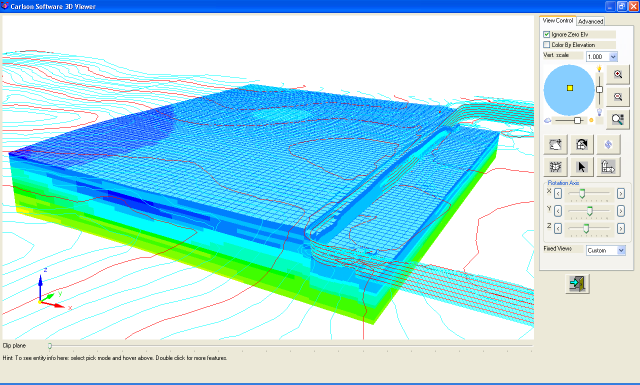

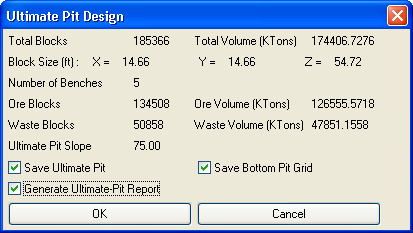

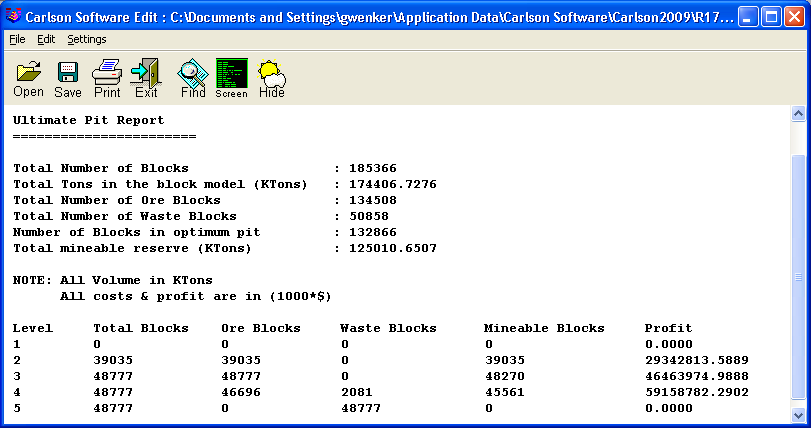

Optimized Pit Design

Now that the Value Block Model is written, the Optimized Pit Design

is run to create the ultimate pit and create the ultimate pit block

model. The Value Block Model is now the file to process, and this

one is selected first. All options are turned on to create an

ultimate pit grid, block model and a report. The block model is

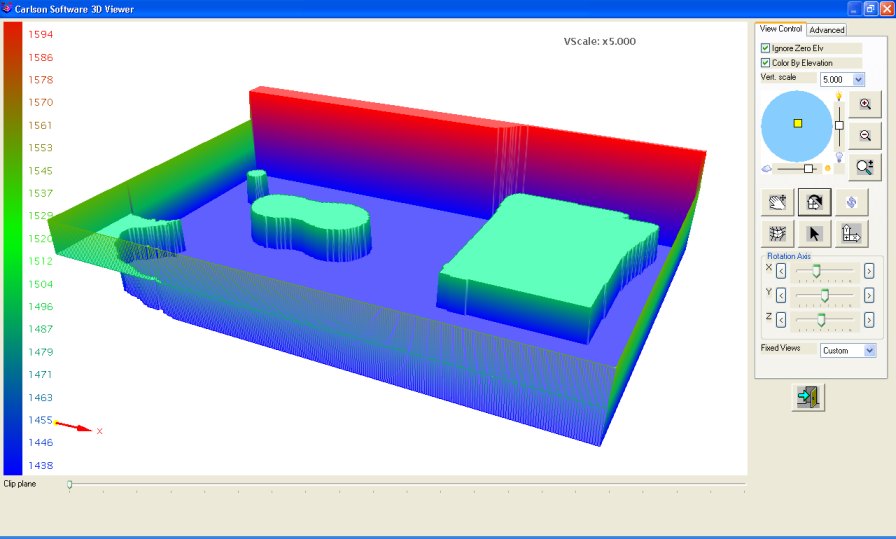

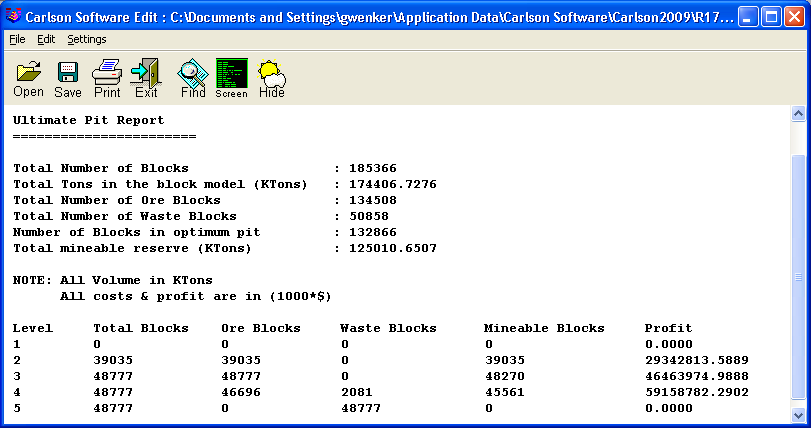

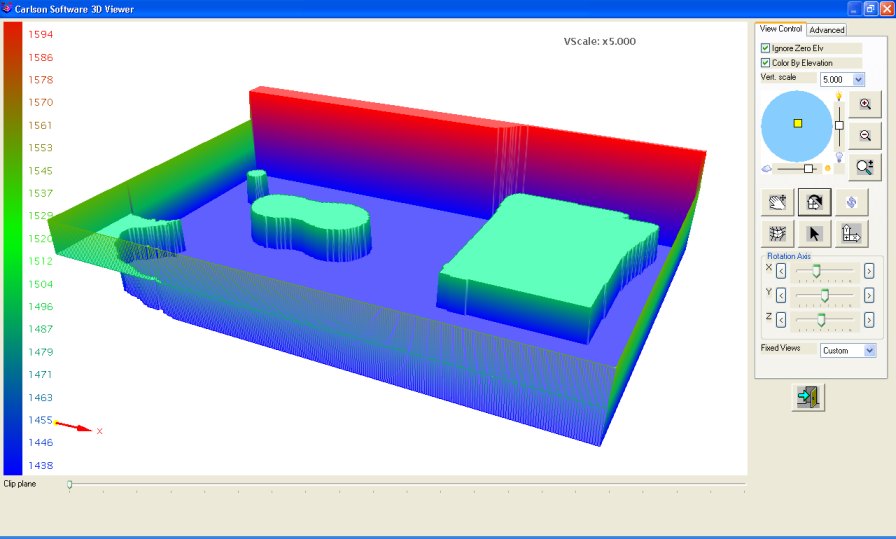

just for calculation purposes and contains cost values.  The final report shows that most of the blocks

are mineable. Level 1 doesn't have anything in it that is mineable.

The lowest level, 5 is not mineable, though there are blocks in it.

The blocks that are not profitable are what is left in the image

below. The grid is displayed here, with the Surface 3D Viewer, and

colored by elevation. It is easy to make changes in the input

parameters and run it again. The cost to mine or process the ore

can be modified and the new cost model created to see how it

affects the output.

The final report shows that most of the blocks

are mineable. Level 1 doesn't have anything in it that is mineable.

The lowest level, 5 is not mineable, though there are blocks in it.

The blocks that are not profitable are what is left in the image

below. The grid is displayed here, with the Surface 3D Viewer, and

colored by elevation. It is easy to make changes in the input

parameters and run it again. The cost to mine or process the ore

can be modified and the new cost model created to see how it

affects the output.

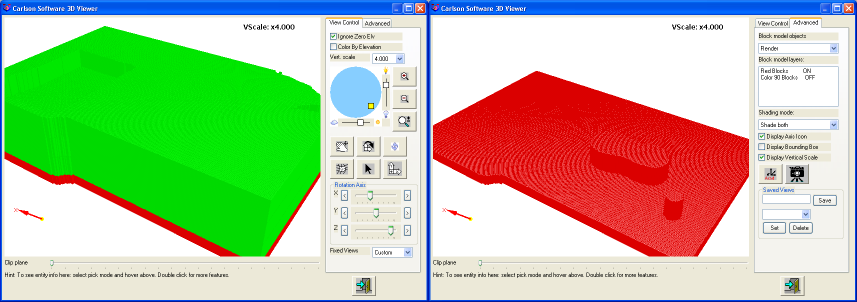

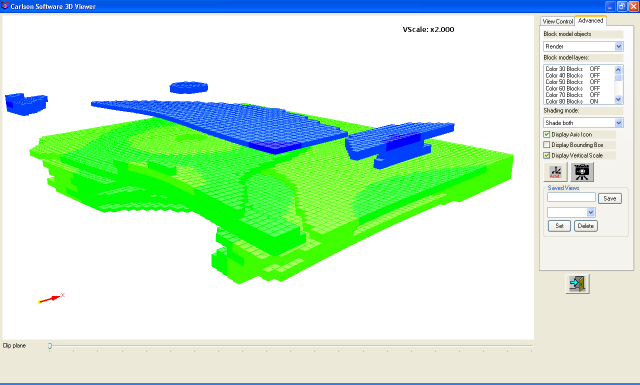

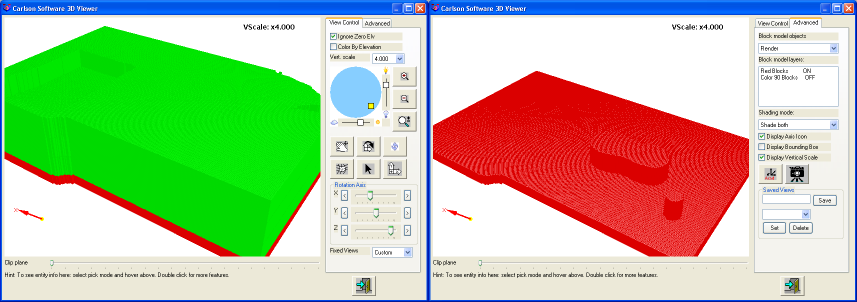

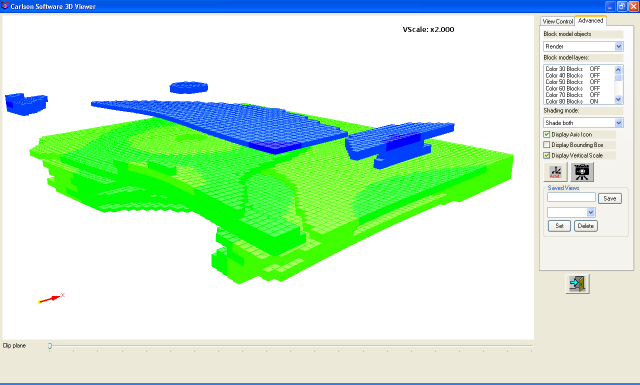

There is an automatic Grade Parameter File

written called the Profit and Loss.GPF. This will colorize the

blocks in the Value Block Model green if they are profitable, and

red if they are not. This final model can also be viewed in 3D and

it will resemble the ultimate pit grid file. Shown below is the

full model, and then the profitable blocks are removed or "frozen"

and just the red, nonprofitable blocks remain.

There is an automatic Grade Parameter File

written called the Profit and Loss.GPF. This will colorize the

blocks in the Value Block Model green if they are profitable, and

red if they are not. This final model can also be viewed in 3D and

it will resemble the ultimate pit grid file. Shown below is the

full model, and then the profitable blocks are removed or "frozen"

and just the red, nonprofitable blocks remain.

Block Model Viewer

Block Model Viewer

The second window sets the block height and

modeling method. There are two distinct methods for setting the

block height. They can be set to a fixed elevation and size which

is independent of the beds, or can follow the top and bottom of the

ore model from the drillholes. This creates almost a stratified

block model where the elevations of the blocks follow the top and

bottom of the ore elevations. This is like a hybrid of both

strata and block modeling. If there are not any strata, such as in

a gold or copper deposit, then the Fixed Elevations method is

preferred. Both methods work the same. If using the Fixed

Elevations method, to set the block height, the top and bottom of

the model are entered, with the number of samples chosen to set the

average block height, which is calculated and displayed at the top.

In this screen, if the Number of Vertical Divisions is set to 16,

the average block height listed above is 10.9. This should work

well with the horizontal size of 20x20, giving an average block

size of 20x20x10. This example will use Inverse Distance as the

modeling method with a vertical factor of 1. Selecting OK builds

all of the blocks and puts them in the BLK file. Choose a name for

the BLK file, such as LS_CaO.BLK.

The second window sets the block height and

modeling method. There are two distinct methods for setting the

block height. They can be set to a fixed elevation and size which

is independent of the beds, or can follow the top and bottom of the

ore model from the drillholes. This creates almost a stratified

block model where the elevations of the blocks follow the top and

bottom of the ore elevations. This is like a hybrid of both

strata and block modeling. If there are not any strata, such as in

a gold or copper deposit, then the Fixed Elevations method is

preferred. Both methods work the same. If using the Fixed

Elevations method, to set the block height, the top and bottom of

the model are entered, with the number of samples chosen to set the

average block height, which is calculated and displayed at the top.

In this screen, if the Number of Vertical Divisions is set to 16,

the average block height listed above is 10.9. This should work

well with the horizontal size of 20x20, giving an average block

size of 20x20x10. This example will use Inverse Distance as the

modeling method with a vertical factor of 1. Selecting OK builds

all of the blocks and puts them in the BLK file. Choose a name for

the BLK file, such as LS_CaO.BLK. Block Model Viewer

Block Model Viewer

There is also an option to draw the

Fence Diagrams in 3D using the Real World Coordinates setting. When

this is viewed in the 3D Viewer Window along with 3D Geologic

Columns, the result is very useful to visualize the geologic

deposit as shown below. The Draw Geologic Column command will draw

the drillholes as 3D columns, and they can also be colorized by the

Grade Parameter File. Notice how the coloration in the drillholes

corresponds to the coloration in the fence cross-sections,

indicating and good modeling estimation.

There is also an option to draw the

Fence Diagrams in 3D using the Real World Coordinates setting. When

this is viewed in the 3D Viewer Window along with 3D Geologic

Columns, the result is very useful to visualize the geologic

deposit as shown below. The Draw Geologic Column command will draw

the drillholes as 3D columns, and they can also be colorized by the

Grade Parameter File. Notice how the coloration in the drillholes

corresponds to the coloration in the fence cross-sections,

indicating and good modeling estimation.

Shown here is the report of the data

dumped into Excel using the Report Formatter. Notice how the total

Key tons match the individual grade tons added up in the yellow

cells. This is a good check to make sure all grades are accounted

for in the report. Also confirm that each grade's CaO falls in line

with the values defined in the Grade Parameter File.

Shown here is the report of the data

dumped into Excel using the Report Formatter. Notice how the total

Key tons match the individual grade tons added up in the yellow

cells. This is a good check to make sure all grades are accounted

for in the report. Also confirm that each grade's CaO falls in line

with the values defined in the Grade Parameter File.

Enter in the Economic Parameters. Shown here is

a sample of the costs associated with the various mining stages.

This writes the value block model, where each block now has a value

assigned to it whether it is profitable or not. This file is named

Value Block Model.BLK.

Enter in the Economic Parameters. Shown here is

a sample of the costs associated with the various mining stages.

This writes the value block model, where each block now has a value

assigned to it whether it is profitable or not. This file is named

Value Block Model.BLK.

The final report shows that most of the blocks

are mineable. Level 1 doesn't have anything in it that is mineable.

The lowest level, 5 is not mineable, though there are blocks in it.

The blocks that are not profitable are what is left in the image

below. The grid is displayed here, with the Surface 3D Viewer, and

colored by elevation. It is easy to make changes in the input

parameters and run it again. The cost to mine or process the ore

can be modified and the new cost model created to see how it

affects the output.

The final report shows that most of the blocks

are mineable. Level 1 doesn't have anything in it that is mineable.

The lowest level, 5 is not mineable, though there are blocks in it.

The blocks that are not profitable are what is left in the image

below. The grid is displayed here, with the Surface 3D Viewer, and

colored by elevation. It is easy to make changes in the input

parameters and run it again. The cost to mine or process the ore

can be modified and the new cost model created to see how it

affects the output.

There is an automatic Grade Parameter File

written called the Profit and Loss.GPF. This will colorize the

blocks in the Value Block Model green if they are profitable, and

red if they are not. This final model can also be viewed in 3D and

it will resemble the ultimate pit grid file. Shown below is the

full model, and then the profitable blocks are removed or "frozen"

and just the red, nonprofitable blocks remain.

There is an automatic Grade Parameter File

written called the Profit and Loss.GPF. This will colorize the

blocks in the Value Block Model green if they are profitable, and

red if they are not. This final model can also be viewed in 3D and

it will resemble the ultimate pit grid file. Shown below is the

full model, and then the profitable blocks are removed or "frozen"

and just the red, nonprofitable blocks remain.